New Major More Work at Low Cost

Page 71

Page 72

Page 73

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

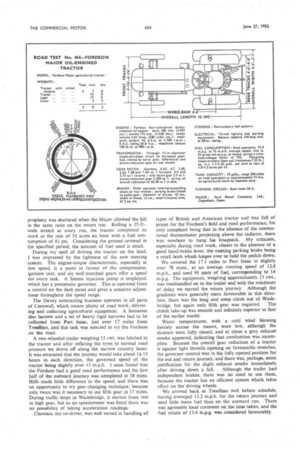

By Laurence J. Cotton, M.I.R.T.E.

BECAUSE of its six-speed gearbox and engine torque characteristics, the new Fordson Major oil-engined tractor can do much more work than its predecessor in a specified period, and the fuel bill is low. Working on a steep hill and ploughing a medium-heavy loam soil at a steady 11 acres an hour, it used 1-11 galls. of oil fuel. On the road it hauled a loaded trailer for 17 miles at an average speed of 13 m.p.h. with a fuel-consumption rate of 13.4 m.p.g.

There is little doubt that the oil-engined tractor is the farmer's tool of the near future, and the new Major, produced at low cost, will advance the trend. A new standard road tractor has not yet been marketed and all my tests were made with the agricultural model, but the general characteristics of the road haulage tractor will be basically similar. The main differences between the new tractor and its predecessor are its power unit, which is interchangeable with petrol and vaporizing-oil engines, its dry clutch, gearbox, a new type of differential brake, recirculatoryball steering and pressurized radiator. Added attractions in its agricultural form are adjustable-track pneumatic tyres and three-point hydraulic lift.

Many of the components, including the main casting and moving units, are common to all three engines, which have overhead push-rod-operated valve gear and a single head covering all four bores. The oil engine is arranged for direct injection, the four-hole injector spraying into central pot-shaped cavities in the piston crowns. Shell-type bearings, a five-bearing crankshaft, pressure lubrication and wet cylinder liners are employed.

A thermostat is supplied in the top water pipe, whilst the running temperature can be controlled by shutters operated from the driving seat. An ethertube thermometer, with the dial on the instrument panel, indicates water temperature in the cylinder head.

Whereas the former tractor had a water capacity of nine gallons, the new model has a system which holds three gallons, but has a pressure valve in the radiator cap which raises the boiling-point of the water and reduces loss from evaporation or spill. A four-bladed fan, water pump and radiator shroud further improve the efficiency of the cooling system.

The 11-in.-diameter single-plate clutch is new and a six-speed gearbox with two selector levers is another innovation. The ratios are paired 1-3, 2-4 and 5-6, and there are two reverse gears. While the main lever is engaging any one of a pair, an alternative gear is selected by moving the second lever either up or down. The range of ratios enables full use to be made of the engine torque under the varying conditions of operation, and relatively more ground is covered in a given period.

To obtain a general picture of the tractor in its road transport and agricultural applications, a standard model with oil engine was made available for my tests in the West Country. With the co-operation of F. Davey and Sons (Tresillian), Ltd., Newquay, the largest agricultural contractor in Cornwall, 1 was provided with a variety of work, fuel for the tractor and an experienced driver to guide me in the art of ploughing and other land operations. To make my observations more complete, a torque dynamometer was provided for the agricultural trials by courtesy of Farm Industries, Ltd., of Truro.

The Fordson Major was ready at the Tresillian home farm and after filling the tank to the brim and preliminary engine warming, an F.R. three-furrow mounted plough was attached. During the first hour, the headland was marked out in a field nearby and two pints of fuel were used in warming-up and in preparatory work. Next, the plough was set. During this period I measured out the field and its general incline, which, in the direction of ploughing, was 45 yds. of 1 in 5 gradient, 80 yds. of 1 in 8 and 100 yds. of 1 in 15. The texture of the soil required third gear when climbing and fourth gear during the return run.

No effort was required on the part of the Fordson to plough 1 1acres an hour, and on a fast timed test, it was working at the rate of 1.43 acres an hour. Fuel consumption varied from 1.25-1.46 gallons per hour, depending on the speed of working.

Among the equipment put at my disposal by Mr. Rex Davey, who is responsible for the agricultural-contract side of the business, was a Ransomes four-furrow trailed plough, and this was impressed for part of the day's work. Working on the same ground, winter fallow, there was a tendency towards wheel-spin when working up the gradient, but reducing tyre pressures to the minimum gave the requisite adhesion. Wheel weights were fitted. The dynamometer was interposed at this point and with a furrow width of 1 ft. and working to a depth of 71 ins., the pull recorded was 2,600 lb. From this I calculated the soil resistance to be 7.22 lb per sq. in. At the time of the trials, the soil was moist and in good condition for ploughing.

In a two-hour test with this trailed plough, which required third gear for the full bout, we worked 2.42 acres of ground and used 2 galls. 5 pts. of oil fuel. As an indicatiOn that the fuel is used to its full efficiency and that the engine cooling capacity is adequate. the radiator shutters were closed through out these trials, yet the water temperature remained below 170 degrees F., even when pulling hard during the times tests. The day temperature ranged from 50-55 degrees F. during the three days' tests.

Having been subjected to a fair trial at ploughing, the Fordson was next attached to a rear-mounted cultivator with 3-in. duckfoot shares set to 8-in. depth.

The morning programme comprised cross-cultivating a 22-acre field, and in three hours the task was twothirds completed. Although the ground was covered at the rate of 41 acres per hour, the Fordson could have operated much faster with such light loading. Fourth gear was found to be most satisfactory for this class of work and on this light loading the fuel consumption was 0.335 galls, per acre, or approximately 14 galls, per hour.

In the corner of the field was a heavy set of triplegang rollers, which, according to local forecast, would be more than the Major could manage on a 1-in-5 gradient. It was a laborious task to line up the rollers astern, to tow them down to the newly ploughed field and assemble them in working position. Rolling is necessarily a slow task, but with the width covered by the equipment, much work can be done in an hour. Second gear was found to be suitable and the local prophecy was shattered when the Major climbed the hill in the same ratio on the return run. Rolling a 25-ft.wide stretch at every run, the tractor completed its work at the rate of 5i acres an hour with a fuel consumption of 81pts. Considering the ground covered in the specified period, the amount of fuel used is small.

During my spell of driving the tractor on the land, I was impressed by the lightness of the new steering system. The engine-torque characteristic, especially at low speed, is a point in favour of the compressionignition unit, and six well-matched gears offer a speed for every task. A Simms injection pump is employed, which has a pneumatic governor. This is operated from a control on the dash panel and gives a sensitive adjustment throughout the speed range.

The Davey contracting business operates in all parts of Cornwall, which means plenty of road work, delivering and collecting agricultural equipMent. A Somerset disc harrow and a set of heavy rigid harrows had to be collected from Port Isaac, just over 17 miles from Tresillian, and this task was selected to try the Fordson on the road.

A two-wheeled trailer weighing 15 cwt. was hitched to the tractor and after inflating the tyres to normal road pressure we drove off along the narrow country lanes. It was estimated that the journey would take about 11-li hours in each direction, the governed speed of the tractor being slightly over 13 m.p.h. I soon found that the Fordson had a good road performance and the first half of the outward journey was completed in 38 mins. Hills made little difference to the speed, and there was no opportunity to try gear-changing technique, because only twice was it necessary to use fifth gear in 17 miles. During traffic stops in Wadebridge, it started from rest in high gear, but as no speedometer was fitted there was no possibility of taking acceleration readings.

Clarence, my co-driver, was well versed in handling all

types of British and American tractor and was full of praise for theFordson's field and road performance, his only complaint being that in the absence of the conventional thermometer projecting above the radiator, there was nowhere to hang his knapsack. My criticism, especially during road work, relates to the absence of a good hand-brake lever, the existing parking brake being a small latch which hinges over to hold the pedals down.

We covered the 17.1 miles to Port Isaac in slightly over 78 mins., at an average running speed of 12.8 m.p.h., and used 91 pints of fuel, corresponding to 14 m.p.g. The equipment, weighing approximately 15 cwt., was manhandled on to the trailer and with the minimum of delay we started the return journey. Although the gradients were generally more favourable in this direction, there was the long and steep climb out of Wade

bridge, but again only fifth gear was required. The clutch take-up was smooth and infinitely superior to that of the earlier model.

Water temperatures, with a cold wind blowing fiercely across the moors, were low, although the shutters were fully closed, and at times a grey exhaust smoke appeared, indicating that combustion was incomplete. Because the overall gear reduction of a tractor is against light throttle opening on favourable stretches, the governor control was in the fully opened position for the out and return journey, and there was, perhaps, some justification for the slight exhaust smoke immediately

after driving down a hill. Although the trailer had independent brakes, there was no need to use them, because the tractor has an efficient system which takes effect on the driving wheels.

We arrived back at Tresillian well before schedule, having averaged 13.2 m.p.h. for the return journey and used little more fuel than on the outward run. There was agreeable local comment on the time taken, and the fuel return of 13.4 m.p.g. was considered favourably.