For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the fender of the best letter which we publish on, this page7 all others are paid for at the rate cd a penny a live, with an allowance for photographs. All notes are edited before being pnblished. Mention, your employer's name, in • confidence, as evidence of good faith, Address, 1)., M. and F., " The

Co7nmerclat Motor," Rosebery Avenue, London, E.C. 1.

Lamps Alight.

On Saturday, the 29th June, light your lamps at 9.49 in London, .10.59 in Edinburgh, 10.16 in Newcastle,

10.11 ia Liverpool, 10.1 in Birmingham," 9.58 in Bristol, and 10.55 in Dublin..

The Acid Treatment. •

The sender of the following communication liar been awarded the IQs. prize this week.

[1871] " (West Dulwich) writes : —" It is not

infrequently found that. new gearwheels designed with a Square hole and intended to slide upon the gearbox 'shaft are somewhat t;ght when erected in place. The garage mechanic is then, to someextent, in a dilemma. The shaft may not be touched, since, In 99 cases of out 100, other gears .slide upon it. These are already in position. Th reduce the shaft to fit the new gear would be to render all the others Slack. The -new gearwheel is hardened all over : a file will not tench it. To soften it is risky, sinee one ilof two things would be stire to result; either the

ear itself would warp, or it would be found impossible to harden it again and bring it to the same State as it was when purchased.. The following method has proved satisfactory in such cases. As it m known to probably only a few, a useful purpose might well be served by publishing it in the columns f your D.M. and F. page, ' A stout piece of sheet rubber should be procured, and laid upon the table of a slotting machine or other ixrailar _part conveniently adapted to take T-head bolts. The gearwheel should be laid upon this sheet ipf rubber, so that one end of the squared hole is Closed by the rubber. A couple of bars can be lad across the wheel, which is then secured in place by

means. of T-headed the passing through these bars and being held in the slots of the table at their other ends. A strong solution of nitric acid should be poured into the hole until it is almost level with the top, a little room being left for the addition of some

killed spirits,' such. as is used for soldering. The acid will immediately commence to take effect upon. the metal, and after tWo or three minutes the gear may be removed, when it will no doubt ha found to be sufficiently free on its shaft to be erected in-place. " In these days of widespread semi-technical education as disseminated in our schools, it is perhaps hardly necessary to warn readers that care must be taken not to spill the acid upon one's clothes or hands, as it will burn either."

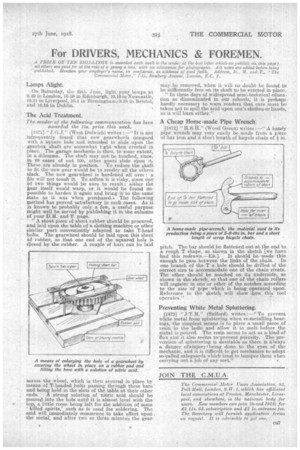

A Cheap Home-made Pipe Wrench.

[1872] " H. 6.11." (Wood Green) writes :—" A handy pipe wrench may very easily be made from a piece of bar iron and a•short length of bicycle chain of in.

pitch. The bar should be flattened out at the end to a rough T. shape, as shown in the sketch [we have had this redrawn.—ED.]. It should bemade "thin enough to pass between the links of the chain. In one branch of the T'a hole should be drilled of the correct size to accommodate one of the chain rivets. The other should be notched on its underside, as shown in the sketch, so that one of the chain rollers will register in one or other of the notches according to the size of pipe which is being operated upon. Reference to the sketch will show -how this., tool Operates,"

PreVenting White Melal Spluttering.

[1873] " (Salford) writes : —" To prevent

white metal from spluttering when re-metalling.-bearings, the. simplest means is to place a small piece of resin in the ladle and allow it to melt. before the metal is poured. The resin seems to act as a kind of flux and it also see-tas to prevent porosity. • The prevention of spluttering is desirable as there is always a danger oft,injury I being done to the eyes of the mechanic, and it is difficult to get mechanics to adopt so-called safeguards which tend to hamper them when cairying out a job of any sort."