WORKSHOP TOOLS AND EXPEDIENTS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Suggestions from Some of Our Driver and Mechanic Readers.

•A LARGE amount of drilling had to

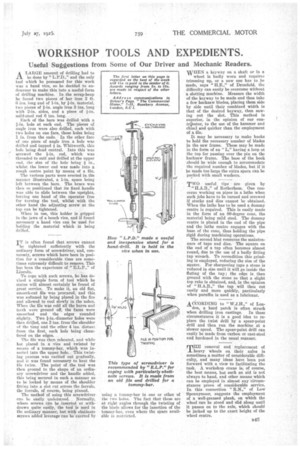

be done by " L.P.D.," and the only tool which he possessed for this work was a hand vice, so he decided to endeavour to make this into a useful-form of drilling machine. In the scrap-heap he found two pieces of bar iron 2 ft. 6 ins, long and of 1-in, by f-in. material, two pieces of 1-in, angle iron 3 ins, long with 2-in, sides, and a piece of 4-in, mild-steel rod 6 ins, long.

Each of the bars was drilled with a :-in. hole at each end. The pieces of angle iron were also drilled, each with two holes on one face, these holes being 1 in. from the ends. In the other face of one piece of angle iron a hole was drilled and tapped f in. Whitworth, this hole being dead central. Into this was screwed the fin, rod, which was threaded to suit and drilled at the upper end, the size of the hole being f in., whilst the lower end was made into a rough centre point by means of a file.

The various parts were erected in the manner illustrated, a 1-in, space being left between the bars. The brace was then so positioned that its fixed handle was able to aide between the uprights, leaving one hand of the operator free for turning the tool, whilst with the other hand the adjusting screw at the top can be tightened.

When in use, this holder is gripped.

• in the jaws of a bench vice, and if found necessary a hand vice can be used for holding the material which is being

• drilled.

IT is often found that screws cannot be tightened sufficiently with the ordinary form of screwdriver, and, conversely, screws which have been in position for a considerable time are sometimes extremely difficult to remove. This has been the experience of "E.L.F.," of Lincoln.

To cope with such screws, he has devised a simple form , of tool which he states will almost certainly be found of great service. To make it, an old fiat, smooth-cut file was procured, and this was softened by being placed in the fire and allowed to cool slowly in the ashes. When the file was cold all the burrs and teeth were ground off, the faces were smoothed and the edges rounded slightly. Two t-in.-diameter holes were then drilled, one 3 ins. from the shoulder of the tang and the other 4 ins. distant from the first, each hole being chamfered on the edges.

The file was then reheated, and while hot placed in a vice and twisted by means of a tommy-bar, which was inserted into the upper hole. This twisting process was carEed out gradually, and it was found necessary to heat the file twice. The point of the tool was then ground to the shape of an ordinary screwdriver and the handle added, this being secured in such a manner as to be locked by means of the shoulder fitting into a slot Cut across the ferrule, the ferrule, of course, being pinned.

The method of using this screwdriver can be 'easily understood. Normally, where screws can be inserted or withdrawn quite easily, the tool is used in the ordinary manner, but with obstinate screws added leverage can be exerted' by using a tonnay-bar in one or other of the two holes. The fact that these are at right angles through the twisting of the blade allows for the insertion of the toramy-bar, even where the space available is restricted. WHEN a keyway on a shaft or in a wheel is badly worn and requires trimming up, or a new one has to be

made, says " of Dronfield, the difficulty can easily be overcome without a slotting machine. Measure the width of the keyway to be made and then take a few hacksaw blades, placing them side by side until their combined width is that of the desired keyway, then sawing out the slot. This method is superior, in the opinion of our cont4butor, to the use of the hammer and eked and quicker than the employment of a file.

It may be necessary th make hooks to hold the necessary number of blades in the saw frame. These may be made in the form of an "L," having a loop at the top for passing over the pin on the hacksaw frame. The base of the hook • should be wide enough to accommodate the required number of blades, but if it be made too large the extra space can be packed with small washers.

TWO useful tips are given by

."H.A.B.," of Rotherham. One concerns working on pipes in a lathe when such jobs have to be turned and screwed if stocks and dies cannot be obtained. When the lathe has to be used a dummy centre is required. This is easily made in the form of an 80-degree cone, the material being mild steel. The dummy centre is placed in the end of the pipe and the lathe centre engages with the base of the cone, thus holding the pipe rigid during machining operations.

The second hint concerns the maintenance of taps and dies. The square on the end of a tap often becomes almost round, due to the use of a badly fitting tap wrench. To recondition this grinding is employed, reducing the size of the square. For sharpening taps a stone is reduced in size until it will go inside the fluting of the tap ; the edge is then ground with the stone so that a slight top rake is obtained, and, in the opinion of "H.A.B.," the tap will then cut easily and more quickly, particularly when paraffin is used as a lubricant.

ACCORDING to " VV.J.EL," of Lon

don, a hard patch is often struck when drilling iron castings. In these circumstances it is a good idea to replace the twist drill by a spear-point drill and then run the machine at a slower speed. The spear-point drill can easily be made from carbon or cast-steel and hardened in the usual manner.

rilHE removal and replacement of

• heavy wheels on their axles is• sometimes a matter of considerable difficulty, and many ideas have been put forward with a view to facilitating the task. A workshop crane is, of course, the best means, but such an aid is not always to hand, and other means which can be employed in almost any 'circumstances prove of considerable service.

In this connection " of Low -Spennytnoor, suggests the employment of a well-greased plank, on which the wheel can be stood and slid along until it passes on to the axle, which should be jacked up to the exact height of the wheel centre.