For DRIVERS, MECHANICS & FOREMEN.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an EXTRA FIVE 'SHILLINGS to the sender of the one whicg-we select as being the best each week. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of goodfaith. Address, D., M. and F., "The Commercial Motor," 7-15, Rosebery Avenue, London, EX. 1.

Lamps Alight.

On Saturday, July 31st, light your lamps at 9.18 in London, 9.52 in Edinburgh, 9.40 in Newcastle, 9.38 in Liverpool, 9.28 in Birmingham, 9.28 in Bristol, and 10.21 in Dublin.

A Crankshaft Lap.

The sender of the following communication has been awarded the extra payment of 5s. this week.

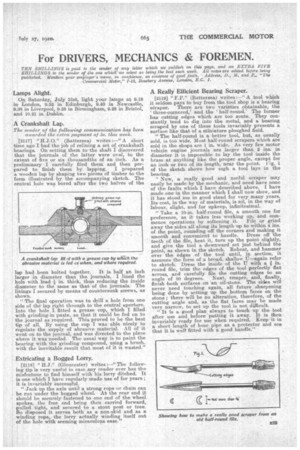

[2117] "II.J.0." (Battersea) writes :—"A short time ago I had the job of relining a set of crankshaft bearings. On setting them to-the shaft I discovered that the journals of the latter were oval, to the extent of five or six thousandths of an inch. As a preliminary I carefully filed them and then prepared to finish them by lapping.. I prepared a wooden lap by shaping two pieces of timber to the form illustrated by the accompanying sketch. The central hole was bored -after the two halves of the

lap had been bolted together. It is half an inch larger in diameter than the journals. I lined the hole with lead in. thick, thus reducing the inside diameter to the same as that of the journals. The linings I secured by means of countersunk serews, as shown.

"The final operation was to drill a hole from one side of the lap right through to the central aperture. Into the hole I fitted a grease. cup, which I filled with grinding-in paste, so that it could be fed on to the journal as required. This proved to be the best tip of all. By using the cup I was able nicely to regulate the supply of abrasive• material. All of • it went on to the journal, and was directed to the place where it was needed. The usual way is to paint the bearing with the grinding compound, using a brush. with the inevitable result that most of it is wasted."

_Extricating a Bogged Lorry.

[2118] " (Gloucester) writes :--" The follow ing tip is very useful in case any reader ever has the misfortune to find himself with his lorry ditched. It is one which I have regularly made use of for years; it is invariably successful.

"Jack up the axle until a strong rope or chain can be run under the bogged wheel. At the rear end it should be securely fastened to one end of the wheel spokes, the free end being then carried forward, pulled tight, and secured to a stout post or tree.

• So dieposed it serves both as a non-skid and as a winding rope, the lorry actually winding itself out of the hole with seeming miraculous ease."

A Really Efficient Bearing Scraper.

[2119] "F.P." (Battersea) writes :—." A tool which it seldom pays to buy from the tool shop is a bearing scraper. There are two varieties obtainable, the three-cornered,' and the 'half-round.' The former has cutting edges which are too acute. They constantly tend to dig into the metal, and a bearing scraped by one of these tools invariably presents a surface like that of a miniature ploughed field.

"The half-round is a better tool, but, as usually sold, is too wide. Most half-round scrapers which are sold in the shops are 1 in. wide. As very few motor vehicle engine journals are larger than, 2 ins, in diameter it is impossible to lay the tool inside the brass at anything like the proper angle, except for an inch or two of its length, near the point. rig, 1 of the sketch shows how sugh a tool lays in the bearing. "Now, a, really good and useful scraper may easily be made by the mechanic, and need have none of the faults which I have described above. I have made one in the manner which I shall now show, and it has stood ins in good stead for very many years. Its cost, in the way of materials' is nil, in the way of labour, slight, and for upkeep, infinitesimal.

"Take a 10-in, half-round file, a smooth one for preference, as it takes less working up, and com

mence operations by softening it. File or grind away the sides all along its length up to within 4 ins. of the point, rounding off the corners and making it smooth and convenient to handle. Dress off the teeth of the file, heat it, turn up the point slightly, and give the tool a downward set just behind the point, as shown in the sketch. Reheat, and hammer over the edges of the tool until, in section, it assumes the form of a broad, shallow U—again refer to sketch. Dress the inside of the U with a in. round file, trim the edges' of the tool perfectly flat across, and carefully file the cutting edges to an angle of 80 degrees. Next, temper, and, finally, finish both surfaces on an. oil-stone. The sides will never need touching again, all future sharpening being done by setting up the bottom faces on. the stone ; there will be no alteration, therefore, of the cutting angle and, as the flat faces may be made very narrow, to set up the tool is not difficult.

"It is a good plan always to touch up the tool after use and before putting it away. It is then invariably ready for use when required. Keep it in a short length of hose pipe as a protector and see that it is welt fitted with a good handle."