THE FUEL QUESTION.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

Prospects of Alcohol Production—Cost and Calorific Values—Gas and the Container Problem—Producer Gas.

FROM THE INTERIM memorandum recently issued by the Fuel Research Board itis evi dent that, in spite of the successful experiments which have been made with the admixture of alcohol with other fuels noimmediate alleviation of the fuel situation can be expected from this source.

It is true that the legislative questions concerninc.' the use of power alcohol are being dealt with milt

t; Finance Bill now before Parliament, and the Revenue Bill shortly to be introduced, but unless supplies are to be readily obtainable, little progress will be made possible. As the memorandum very rightly points out, so long as the raw materials available for alcohol production are imported or home-grown foodstuffs, we must look for other and cheaper sources of power. The memorandum alludes to research work which has already been initiated, with a view to devising satisfactory laboratory processes for the production of power alcohol from the unlimited quantities of tropical vegetation that are to be found in various parts of the Empire ; but, even if a satisfactory pro cess is eventually evolved,' considerable time must necessarily elapse before supplies of power alcohol could be available. Therefore, as, the Director of Fuel Research has pointed out, coal is likely to remain—for a long time, at any rate—the world's principal source of fuel; and, in this country, where it is tire natural source of heat and

power, wo 'have, at present, no alternative but to concentrate o n the adattation of• its products for transport p u r poses.

We have, therefore, to consider the way in which t h a constituents of raw coal can be divided up into gaseo is, liquid and solid fuels, so that the potential heat units can be made available, in the forms most suited to the required purpose. Re cent developments in gasification processes have resulted in frbm 8,000,000 to 9,000,000i of 'the 30,000,000 of B.T.U.s in a ton of coal being obtained in the gaseous products, 3,500,000 in the liquid products, a.nd 15,000,000 in the coke.

COAL GAS.

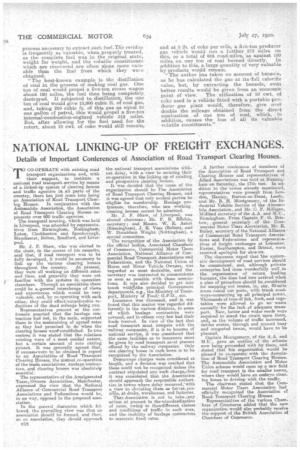

PRODUCER GAS (rriatte from Anthracite at £3 alen

CONE.

glOWSNAISIO

ALCOHOL at 5; a Gallon.

:;.,04:0Aftp,::,:040LAMINgt PETROL al a' a Gallon. (.5hoded/borear)

'Comparative Costs.

In comparing the relative costs of various fuels. in terms of the M.T.U.a obtainable from them some interesting figures are given in the memorandum. The cost of 1,000,000 B.T.U.s in the form of petrol at 3s. per gallon is about 21s, that is to say, two' and-a-half times the cost of 1,000,000 B.T.U.s in the form of gas, and 14 times the -coat of the same calorific value in coke. Taking alcohol at 5s. Per gallon, 1,000,000 B.T.U.s would cost about 52s. We see,' therefore, that on the basis of heat production —which is ultimately power production, if we neglect the efficiency of the method of conversion into power—as a power-producing fuel, alcohol is by far the most expensive of the various products to which reference has been made. Next to coke, gas is obviously the cheapest fuel to use, and it is interest

ing to note that, in their memorandum, the Fuel Research Board suggest that town and coke-oven gas might be extensively used for omnibuses arkd passenger -cars for quick traffic, if light and safe containers could be developed and refilling stations established on the principal roads.

This is a development to which we have devoted much attention in the past, and for which we see great prospects. The development of the design and construction of the gasbags, as used during the war, was cut short by the scarcity of gas, and, while that form of container was adrnittediy a makeshift, hurriedly adapted to tide over an emergency, had investigation proceeded along those-lines, we are confident that a much more satisfactory device would have 'resulted. The production of a safe and comparatively light form of container should not be beyond the ingenuity of our engineers, especially when it is appreciated that the .low temperature carbonization process assists the problem. If the -carbonization of coal at about 600 degrees Centigrade becomes common, gas of twice the calorific value of town, gas would be avallable, so that-twice the number of thermal units could be carried in.the containefs, --which would mean that either the volume, or the pressure at which the gas was stored, could be reduced.

Producer Gas Prospects.

asaktite The memora.ndum also refers to ..Nthe suitability of coke, produced by the' -low temperature processes, for use in suction-gas

Comparative cost of various producers. I t forms of fuel in terms of states that the

the heat units they contain. cost would not ex

ceed 3s. per :1,000,000 B.T.U.s, which is approximately one-seventh of the cost of the equivalent number of units obtainable.from petrol at 3s. per gallon.. In the solution of the fuel problem the gas-producer should, therefore,. play an important part. Recently, some remarkable results of experiments which had been carried out with the Smith gasproducer were published in The Commercial Motor, showing that great success.. is attending the develop

ment of this appliance. In considering .the fuel question, it may, therefore, be of interest to quote the following extract from the paper read: by Lieut.Colonel D. J. Smith before the Institution of AutoMobile Engineers at the beginning of the year :-

"Solid fuels present the only method whereby the high cost of liquid fuels can be countered and the general position made less unsatisfactory and these 'can be used without destroying any material from which liquid fuels might be extracted. • For instance,, coke, charcoal, and dried peat represent the reside left after the liquid fuels have been extracted, so the utmost value is got out of the material Used in providing fuel for both light and heavy motor vehicles. In the case of anthracite, there are practically no volatile constituents, so this fuel, if used directly, entails no loss to the liquid supply. "It has long been the author's firm opinion that every material from which any form of liquid fuel is obtainable should, before being used, be subjected, as far as it is possible, to the process necessary to extract such fuel. The residue is frequently as valuable, when, properly treated, as the complete fuel was in the original state, weight for weight, and the volatile constituent's which are recovered are often alone more valuable than the fuel from which they we e obtained.

"The best-known example is the distillation of c68.1 in the process of making coal gas. One ton of coal would propel a fire-ton steam wagon about 160 miles, the fuel than being completely destroyed. If subjected to distillation, the one ton of coal would give 13,000 cubic ft. of coal gas, and, taking. 250 cubic ft. of this gas as equal to one gallon of petrol, this would propel a five-ton internal-combustion-engined vehicle 312 miles. But, after allowing for the fuel usedfor the retort, about 10 cwt. of coke would still remain, • and at 3 lb. of coke per mile, a five-ton producer gas vehicle would run a further 373 miles on this, or a total of 685 road-miles, as against 160 miles on one ton of coal burned directly. In addition to this, a large quantity of very valuable by-products would remain, The author has taken no account of benzole, as he has calculated the gas at its 'full calorific value, but, by extracting the benzoic, even better results would be given from an economic point of view. The utilization of in cwt. a coke used in a vehicle fated with a portable producer gas plant would, therefore, give ore/double the mileage obtained from the direct combustion of one ton of coal, which, in addition, causes the loss of all its valuable volatile constituents."