COMPLYING WITH POLICE BUS REQUIREMENTS.

Page 9

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

How the Stipulations of Scotland Yard are Followed, Giving Safety and Silence in Public Service.

WHEN the enormous number of buses now running in the metropolitan area—over 4,000—is taken into consideration and compared with the extremely small number of accidents which can, in any way, be attributed to mechanical defects in the construction of these buses, it becomes clear that the regulations insisted upon by the Metropolitan Police have had the effect of bringing into existence a vehicle which is safe and silent and which can be driven in the crowded streets of cities without inconvenience to other traffic. It is true that, in the early days of the London bus, the police regulations were severely criticised by some engineers who found it hard to fall in with some of the points insisted upon, but one does not hear much grumbling to-day.

The regulations of other great cities such as Manchester and Birrninghd'm do not differ to any appreciable extent from those of London, excepting in the matter of body construction, 13odies being allowed there which would not be acceptable for London. On the 'other hand, certain regulations may be hecessary in provincial districts which are not needed in London.

With the exception of such hilly districts as Sydenharn and Highgate there are not many London suburbs where buses operate on hilly routes or which require anything more effective in chassis equipment than the ordinary brakes. There are, however, a few points which do not seem to be perfectly clear. The clearance of 10 ins, under all parts excepting steering heads and steering arms is required to extend so far back as the rear axle, but it is not perfectly clear whether this definitely ex

eludes the rear aale. Chassis designers for London bus requirements, however, regard the rear axle as excluded.

The greatest difficulty which constuctors of buses have met with in getting their products passed by the police is the degree of silence insisted upon. -All other matters are easily settled by measurement, but silence is more or less a matter of opinion, no two persons holding exactly similar views. Even those who have had the greatest experience in bus construction and reconstruction have encountered considerable difficulty in producing buses which come up to the required standard -of quietness. Many efforts have been made to produce gearboxes which will not only run quietly when new, but which will remain quiet and can . be relied upon not to be noisy after reconditioning._ With regard to the final drive, there was no trouble after the wotra replaced the earlrer types' of drive, as the worm can always be relied 'upon for silence. Every ',bus now running inLondon. is equipped with a worm drive, with the exception of the later types made by the Associated Equipment Co.' in which the pinion and rack ring has been revived. Considering the trouble which was experienced through the noise produced by this class of drive in the earlier days of the motorbus, it speaks very highly for the engineering skill which has been brought to bear on this long-abandoned device, and raised it from one of the noisest drives to one which will now compare favourably with any other form for silence.

Even now this form of drive would probably never have seen the light of day again had it not been for the efforts made to reduce the height of the platform, with the ultimate object of asking for a covered-in top. It is not easy to see the reason why covered-in tops are not permitted, as London is particularly favourable for their use, having no low bridges, as is proved by the number of routes used by the covered trams. So long ago as 1909 the Corporation of Widnes ran buses with covered tops, without, so far as we know, having any accidents to record. If the reluctance to grant permission for their -use in London is due to fear of their being blown over, we think that the fear can be dismissed, as, if such buses will stand up on the exposed banks of the Mersey estuary, there is little to be feared from the gales we get in London.

The Straker-Squire Bus Chassis.

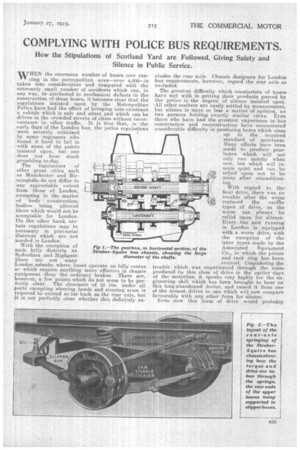

The general lines of the StrakerSquire bus are so well known that there is no need to describe more than, thosefeatures which bear some relation to the particular regulations insisted upon by the Metropolitan police, and oertain points which help to make the chassis successful as a bus. As in all other chassis which are destined to be used as buses, the gearbox had to . receive special attention in order to secure silent running. This was accomplished mainly by the use of cast-iron for the shell of the box, which is less resonant than aluminium, and by means of the very -stiff shafts and ample bearinp employed. A sectional drawing on the shaft line is given in Fig. 1.

Air-hardening steel is used for the gears, and great care is taken in the cutting and depthing of the teeth.

The engines as usually turned out are fitted with a governor.

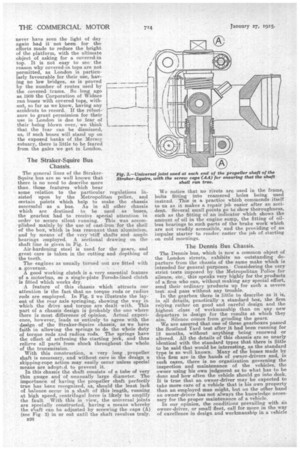

A good working clutch is a very essential feature of a motorbus, so a single-plate Perodo-lined clutch is fitted which works dry. A feature of this chassis which attracts our attention is the fact that no torque rods or radius rods are employed. In Fig. 2 we illustrate the layout of the rear axle springing, showing the way in which the drive and torque are dealt with. This part of a chassis design is brobably the one where there is most difference of opinion. Actual experience, however, leads us entirely to agree with the design of •the Straker-Squire chassis, as we have faith in allowing the springs to do the whole duty of torque rods and radius rods. The springs have the effect of softening the starting jerk, and thus relieve all parts from shock throughout the whole of the transmission.

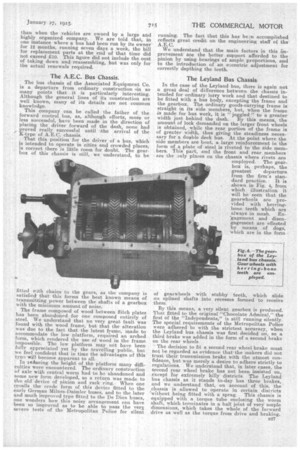

With this construction, a very long , propeller shaft is necessary, and without care in the design a skipping-rope action may easily occur unless special means are adopts d to prevent it. In this chassis the shaft consists of a tube of very thin gauge and of unusually large diameter. The importance of having the propeller shaft perfectly true has been recognized, as, should the least lack of balance occur in a shaft of this length, running at high speed, centrifugal force is likely to amplify the fault. With this in view, the universal joints are specially constructed, having a means whereby the shaft can be adjusted by screwing the caps (A) (see Fig 3) in or out until the shaft revolves truly. We notice that no rivets are used in the frame, bolts fitting into reamered holes being used instead. This is a practice which commends itself to us as it makes a repair job easier after an accident. Several small points go to show thoroughness, such as the fitting of an indicator which shows the amount of oil in the engine sump, the fitting of oil. less bearings to such parts of the brake work which are not readily accessible, and the providing of an impulse starter to render eaaier the job of starting on cold mornings.

The Dennis Bus Chassis.

The Dennis bus, which is now a common object of the London streets, exhibits no outstandin& departure from the chassis of the same make which is intended for general purposes. Considering the very strict tests imposed by the Metropolitan Police for silence, etc., this speaks very highly for the products of a firm who can, without making any special effort, send their ordinary products up for such a severe test and pass without any trouble. In the gearbox there is little to describe as it is, in all details, practically a standard box, the firm relying rather on good and careful design and the highest class of workmanship than on any new departure in design for the results at which they aim. Silence comes from grinding the gears. We are assured that one of these gearboxes passed the Scotland Yard test after it had been running for 12 months, without anything being renewed or altered. All the details of this chassis are so nearly identical with the standard types that there is little to be said that would be interesting, as the standard type is so well known. Many of the buses made by this firm are in the hands of ovSner-drivers and, in such cases, there is no organization governing the inspection and maintenance of the vehicles, the owner using his own judgment as to what has to be done and how often the vehicle should go into dock. It is true that an owner-driver may be expected to take more care of a vehicle that is his own property than an employed man might, but on the other hand an owner-driver has not always the knowledge necessary for the proper maintenance of a vehicle. In our opinion, the conditions prevailing with an owner-driver, or small fleet, call for more in the way of excellence in design and workmanship in a vehicle than when the vehicles are owned by a large and highly organized company. We are told that, in one instance where a bus had been run by its owner for 12 months, running seven days a week, the bill for replacement parts at the end of that time did not exceed 210. This hgure did not include the cost of taking down and reassembling, but was only for the actual renewals required.

The A.E.C. Bus Chassis.

The bus chassis of the Associated Equipment Co. is a departure from ordinary construction -in so many points that it is particularly interesting. Although the general lines of its construction are well known, many of its details are not common knowledge. This company can be called the father of the forward control bus, as, although efforts, more or less successful, have been made in the direction of placing the driver forward of the dash, none had proved really successful until ethe arrival of the K-type of A.E.C. chassis.

That this position for the driver of a bus, which is intended to operate in 'cities and crowded places, is correct there is little room for doubt. The gearbox of this chassis is still, we understand, to be fitted with chains to the gears, as the company is satisfied that this forms the beat known means of transmitting power between the shafts of a gearbox with the minimum amount of noise.

The frame composed of wood between flitch plates has been abandoned for one composed entirely of steel. We understand that no very great fault was found with the wood frame, but that the alteration was due to the fact that the latest frame, made to accommodate the low platform, required an arched form, which rendered the use of wood in the frame impossible. The low platform may net have been fully appreciated yet by the travelling public, but we feel confident that in time the advantages of this type will become apparent to all.. In reducing the height of the platform many difficulties were encountered. The ordinary construction of axle with central worm had to be abandoned and some new form developed, so a return was made to the old device of pinion and rack ring. When one means the crude form of this device fitted to the early German Milnes-Daimler buses, and to the later and much improved type fitted to the De Dion buses, one wonders how this noisy arrangement can have been so improved as to be able to pass the vere severe tests of the Metropolitan Police for silent running. The fact that this has been accomplished reflects great credit on the engineering staff of the A.E.C.

We understand that the main factors in this improvement are the better support afforded to the pinion by using bearings of ample proportions, and to the introduction of an eecentric adjustment for correctly clepthing the teeth.

The Leyland Bus Chassis

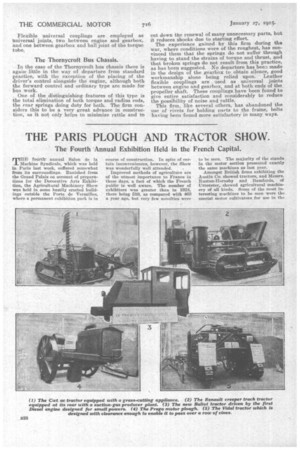

In the case of the Leyland bus, there is again not a great deal of difference between the chassis intended for ordinary lorry work and that destined to be fitted with a bus body, excepting the frame and the gearbox. The ordinary goods-carrying frame is straight in its side members, but, when the frame is made for bus work, it is "joggled" to a greater width just behind the dash. By this means, the amount of lock demanded on the larger front wheels is obtained, while the rear, portion of the frame is of greater width, thus giving the steadiness necessary for a double deck bus. At the point where the side members are bent, a large reinforcement in the form of a plate of steel is riveted to the side members. This part, and the front and rear members are the Drily places on the chassis where rivets are employed. The gearbox is, perhaps, the

greatest departure from the firm's stan

dard practice. It is shown in Fig. 4, from which illustration it will be seen that the gearwheels are provided with herringbone teeth which are always in mesh. Engagement and disengagement are effected by means of dogs, which are in the form

of gearwheels with stubby teeth, which slide on splined shafts into recesses formed to receive them.

By this means, a very silent gearbox is produced. That fitted to the original "Chocolate Admiral," the first of the "Independents," is still running silently. The special requirements of the Metropolitan Police were adhered to with the strictest accuracy, when the Leyland bus chassis was first decided on, so a third brake was added in the form of a second brake on the rear wheels.

The decision to fit a second rear wheel brake must not be regarded as evidence thatethe makers did not trust their transmission brake with the utmost confidence, but was merely a desire to adhere strictly to regulations. We understand that, in later cases, the second rear wheel brake has not been insisted on, except or extremely hilly districts. The Leyland bus chassis as it stands to-day has three brakes, and we understand that, on account of this, the chassis is allowed to operate in certain districts 'without being fitted with a sprag. This chassis is equipped with a torque tube enclosing the worm shaft, which terminates in a ball joint of very ample dimensions, which takes the whole of the forward drive as well as the torque from drive and braking. Flexible universal couplings are employed as ttniversal joints, two between engine and gearbox, and one between gearbox and ball joint of the torque tube.

The Thornycroft Bus Chassis.

In the case of the Thornycroft bus chassis there is againlittle in the way of departure from standard practice, with the exception of the placing of the driver's control alongside the engine, although both the forward control and ordinary type are made for bus work.

One of the distinguishing features of this type is the total elimination of both torque and radius rods, the rear springs doing duty for both. The firm considers this to be a very great advance in construction, as it not only helps to minimize rattle and tti cut down the renewal of many unnecessary parts, but it reduces shocks due to starting effort.

The experience gained by this firm during the war, where conditions were of the roughest, has convinced them that the springs do not suffer through having to stand the strains of torque and thrust, and that broken springs do not result from this practice, as has been suggested. No departure has been made in the design of the gearbox to obtain silence, good workmanship alone being relied upon. Leather flexible couplings are used as universal joints between engine and gearbox, and at both ends of the propeller shaft. These couplings have been found to give entire satisfaction and considerably to reduce the possibility of noise and rattle.

This firm, like several others, has abandoned the use of rivets for holding parts to the frame, bolts having been found more satisfactory in many ways.