WESTINGHOUSE POWER-BRAKE DEVELOPMENTS.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

Pedal-controlled Valve a New Feature. How the System can be Applied to Steam Wagons.

WE have often commented upon the need for devoting more attention to the braking of heavy commercial vehicles, not only in the direction of decreasing the stopping distance, but also to reduce the fatigue of driving. The Westinghouse power brake goes a long way towards fulfilling both of these reqnirements, and is making steady progress towards popularity. The system has been gradually improved since its inception, the latest feature being the provision of a foot-controlled valve, should the customer desire it, in place of the hand lever on the steering column.

We are informed that, although the foot control presents many advantages, many drivers prefer the hand lever, because, on a long gradient, the valve can be set and left in position, whereas the pedal requires continual application. However, the pressure required is hardly more than that needed to depress an accelerator pedal, so that the labour involved in keeping the brakes on is only slight.

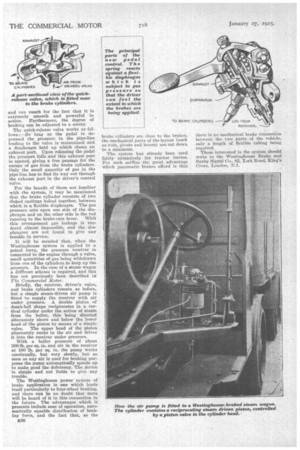

In our view the principal advantage of the foot control is that the driver can actually feel the extent to which he is applying the brakes. As will be seen from the sectional drawing reproduced, the depression of the pedal first closes the exhaust opening and then places the brake cylinders in communication with the air reservoir. In so doing a spring is compressed and reacts against a diaphragm subject to air pressure. Consequently, the degree of pressure which the driver's foot is exerting corresponds to the air pressure in the brake cylinders end is, therefore, proportional to the braking effect produced.

Another feature of the Westinghouse system is a diaphragm valve placed near to the brake cylinders which releases the air immediately upon the removal of pressure from the brake pedal. With this arrangement there is no lag in the system, the brakes coining " off " as quickly as in any mechanical layout.

We witnes ed a practical demonstration of the sys em applied to a 3-ton lorry, and can vouch for the fact that it is extremely smooth and powerful in action. Furthermore, the degree of braking can be adjusted to a nicety.

The quick-release valve works as follows :—So ' long as the pedal is depressed the pressure in the pipe-line leading to the valve is maintained and a diaphragm held up which closes an exhaust port. Upon releasing the pedal the pressure falls and this exhaust port is opened, giving a free passage for the escape of gas from the brake cylinders. Only the small quantity of gas in the pipe-line has to find its way out through the exhaust port in the driver's control valve.

For the benefit of those not familiar with the system, it may be mentioned that the brake cylinder consists of two dished castings bolted together, between which is a flexible diaphragm. The gas pressure acts upon one side of the diaphragm and on the other side is the rod running to the brake-cam lever. With this arrangement gas leakage is rendered almost impossible, and the diaphragms are not found to give any trouble in service.

It will be recalled that, when the Westinghouse system is applied to a petrol lorry, the pressure receiver is connected to the engine through a valve, small quantities of gas being withdrawn from one of the cylinders to keep up the pressure. In the case of a steam wagon a difrArent scheme is required, and this has not previously been described in The Commercial Motor.

Briefly, the receiver, driver's valve, and brake cylinders remain as before, but a simple steam-driven air pump is fitted to supply the receiver with air under pressure. A double piston of dumb-bell shape reciprocates in a vertical cylinder under the action of steam from the boiler, this being directed alternately above and below the lower head of the piston by means of a simple valve. The upper head of the piston alternately sucks in the air and drives it into the receiver under pressure.

With a boiler pressure of about 200 lb. per sq. in. and air in the receiver at 100 lb. per sq. in. the pump works continually, but very slowly, but so soon as any air is used for braking purposes the pump automatically speeds up to make good the deficiency. The device is simple and not liable to give any trouble.

The Westinghouse power system of brake application is one which lends itself particularly to four-wheel braking, and there can be no doubt that more will be heard of it in this connection in the future. The advantages which it presents include ease of operation, automatically equable distribution of braking force, and the fact that, as the

30 brake cylinders are close to the brakes, the mechanical parts of the layout (such as rods, pivots and levers) are cut down to a minimum.

The system has already been used fairly extensiyely for tractor lorries. For such set-rice the great advantage which pneumatic brakes afford is that

there is no mechanical brake connectiOn between the two parts of the vehicle, only a length of flexible tubing being required.

Those interested in the system should write to the Westinghouse Brake and Saxby Signal Co., 82, York Road, King's Cross. London. N.1.