Tinsdale and Terberg: two for the road

Page 24

Page 25

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

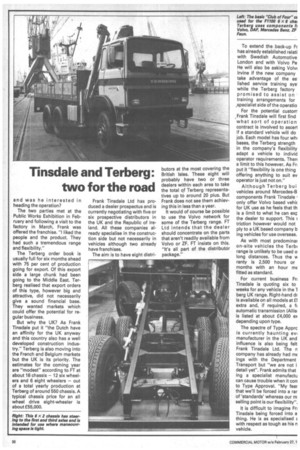

The Dutch company makes a wide range of vehicles and has the ex IVECO man as UK agent

FRANK TINSDALE has long been associated with the commercial vehicle industry so it came as no surprise when he reappeared on the scene following his departure from the driving seat at IVECO UK. What might have come as a surprise, however, writes Graham montgomerie, is whose driving seat he would choose to sit in. It wasTerberg's.

Based at Winsford in Cheshire, the new company, Frank Tinsdale Ltd, will be the sole agents in the UK for vehicles manufactured by the Dutch company.

The fact that Frank Tinsdale Ltd is based at Winsford — the home of IVECO and also formerly of Magirus Deutz — is pure coincidence. Frank was looking at the Cheshire area in general terms as being convenient for access by road via M6 and M62 and by air through Manchester airport. Helooked at Macclesfield and Wilmslow. Then the Winsford offices became available for immediate occupation, at a sensible price, and Frank Tinsdale returned to Winsford.

Terberg is not a household name to UK operators and usually only occurs in CM in the Amsterdam show reports. A little background information will not go amiss.

The company, Terberg Benschop BV, has been a family concern for some 80 years and is still controlled by the Terberg family. Originally involved in general metal work, the company came onto the vehicle scene at the end of World War II. At this time lorries were not plentiful in the Netherlands so .1 Dutch government bought ex-military vehicles mainly of 3 manufacture, to get its ulage industry moving again. rberg got involved in adapting a vehicles for civilian use.

From adapting military hides, it was a gradual evolu'nary process to the present t-up whereby Terberg uses mponents from other menucturers to build its own hides badged with the family me. The word "proprietary" is It as apt in this context as it mild be if, say, Cummins or Iler components were used. ,rberg in the main uses enles, gearboxes, axles, and bs from Volvo although some pc:leis incorporate MercedesIn components.

It could be argued that Terwg is in competition with alvo who after all do make -nilar vehicles. Frank Tinsdale quick to refute this suggestion mover. "The Terberg policy is build what the big manufacrers aren't interested in from a volume point of view". This a similar argument to that ;ed by David Hargreaves at astair Dennis.

Although Terberg may be ought of as building "one-off oecials" the Dutch company akes a wide range of standard ohicles although describing an x 8 as "standard" takes some atting used to.

The F1900 8 x 8 is a typical :ample of what Terberg gets r to. This uses a Volvo TD 100 engine rated at 191 kW (260 1p) at 2200 rpm driving rough a twin-plate clutch to a ;-speed Volvo SR62 gearbox. le axles are Terberg with a pacity of nine tonnes each at the front and 13 tonnes each at the rear. The first Terberg in the UK was delivered a few weeks ago and is an F1900.

The type numbers have no significance in that they do not give any details of the vehicles spec in the way that, say, the 16.28 Roadtrain does for Leyland. The F1900 uses the Volvo F7 cab but if a gross design weight of 44 tonnes is not enough then Terberg also offers an 8 x 8 built around the F12 with an F12 cab and the TO 120E engine rated at 240 kW (326 bhp) DIN.

This particular "animal" known as the F2000 uses Faun

axles with capacities of 121/2 tonnes and 15 tonnes respectively front and rear. An interesting feature of these Terbergs is the suspension which uses American "Ridewell" rubber suspension at the rear and air at the front in conjunction with parabolic leaf springs. Terberg has used air suspension since the introduction of the 8 x 8 some eight years ago. Rubber suspension at the rear is standard for the eight-wheelers and optional on the three axle machines.

Volvo components are also used for the TS60 pipe carrier which is again an 8 x 8 and can transport six tubes of 1.05m (3ft 5in)) diameter and 24m (78ft 8in) in length. It is adjustable •in length and has a gvw of 73 tonnes for a payload of 45 tonnes.

The steering • layout of this vehicle is particularly interesting in that all axles are steered using hydraulic rams with the synchromisation between front and rear bogies through a mechanical connection. The TS60 has a top speed of 60 km/h (37 mph) and a crawling speed of 5 km/h (3 mph)).

Not all Terberg's production is at the heavy end of the market nor is it necessarily all-wheel drive. The F1150 is a 4 x 4, 16 tonner with only its high ground clearance (and the badge!) giving away the fact that it is not a standard F6 Volvo.

For use in constricted areas Terberg builds a 6 x 2 chassis with steering to the first and third axles. Only the driven axle is fitted with twin tyres with the others using big singles. Depending on the individual spec this special 6 x 2 can gross 20 to 24 tonnes.

So much for the technical side of Terberg. Now what about the organisation? After all a vehicle is only as good as its back up. The start of Frank Tinsdale Ltd goes back to January of last year when the Terberg sales director contacted Frank at his home on the Isle of Man. The company wanted to enter the UK market and was he interested in heading the operation?

The two parties met at the Public Works Exhibition in February and following a visit to the factory in March, Frank was offered the franchise. "I liked the people and the product. They had such a tremendous range and flexibility."

The Terberg order book is usually full for six months ahead with 75 per cent of production going for export. Of this export side a large chunk had been going to the Middle East. Terberg realised that export orders of this type, however big and attractive, did not necessarily give a sound financial base. They wanted markets which could offer the potential for regular business.

But why the UK? As Frank Tinsdale put it "the Dutch have an affinity for the UK anyway and this country also has a well developed construction industry." Terberg is also moving into the French and Belgium markets but the UK is its priority. The estimates for the coming year are "modest" according to FT at about 18 chassis — 12 six wheelers and 6 eight wheelers — out of a total yearly production at Terberg of around 550 chassis. A typical chassis price for an all wheel drive eight-wheeler is about £55,000. Frank Tinsdale Ltd has produced a dealer prospectus and is currently negotiating with five or six prospective distributors in the UK and the Republic of Ireland. All these companies already specialise in the construction side but not necessarily in vehicles although two already have franchises.

The aim is to have eight distri butors at the most covering the British Isles. These eight will probably have two or three dealers within each area to take the total of Terberg representatives up to around 20 plus. But Frank does not see them achieving this in less than a year. It would of course he possible to use the Volvo network for some of the Terberg range. FT Ltd intends that the dealer should concentrate on the parts that aren't readily available from Volvo or ZF. FT insists on this. "It's all part of the distributor package."

To extend the back-up Fr has already established relati with Swedish Automotive London and with Volvo Pe He will also be asking Volvt Irvine if the new company take advantage of the es. lished service training sys' while the Terberg factory promised to assist on . training arrangements for ,specialist side of the operatio

For the potential custorr , Frank Tinsdale will first find what sort of operation contract is involved to asceri if a standard vehicle will do job. Each model has four will bases, the Terberg strength in the company's flexibility adapt a vehicle to individ operator requirements. Then a limit to this however. As Fr. put it "flexibility is one thing offering anything to suit ev operator is just not on."

Although Terberg bui vehicles around Mercedes-B components Frank Tinsdale only offer Volvo based vehic for UK use as he feels that th is a limit to what he can exp the dealer to support. This triction however would not ply to a UK based company b ing vehicles for use overseas.

As with most predominar on-site vehicles the Terbt range is unlikely to be used o long distances. Thus the VI ranty is 2,500 hours or months with an hour ITIE fitted as standard.

For current business Fri Tinsdale is quoting six to weeks for any vehicle in the 1 berg UK range. Right-hand dr is available on all models at extra and, if required, a ft automatic transmission (Allis, is listed at about £4,000 e)g depending upon type.

The spectre of Type Apprc is currently haunting evi manufacturer in the UK and influence is also being felt Frank Tinsdale Ltd. The n company has already had mE ings with the Department Transport but "we are not i detail yet". Frank admits that ing a specialist manufactu can cause trouble when it con to Type Approval. "My fear that we'll be forced into a rar of 'standards' whereas our m selling point is our flexibility".

It is difficult to imagine Fn Tinsdale being forced into a thing. He is as specialised z' with respect as tough as his n vehicle.