sM0 0 • A RRIVING in Manchester on the day before I

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

tested the Crossley double-decker bus chassis, I --was able to obtain a pre-view of its performance by travelling in one of the 8-ft.-wide vehicles supplied to Manchester Corporation.. The granite-sett road surfaces of the Manchester suburbs left no doubt that the passengers benefited by the excellent Suspension. When cornering, there was notably little body sway, and I was • favourably impressed by the quietness of both engine and gearbox, although I was sitting in the front seat of the lower saloon; Where noise would be most noticeable. Generally, the Crossley chassis leaves an impression of good modern design based on welbtried .principles, and it is likely to outlive the 10-12-year period normally regarded as the life of a passenger vehicle.

In particular, the chassis frame, which is of 11-in. by 3-in. by I-in. section, is welt reinforced, by flitch plates bolted to the inside of the frame over the engine and wheel-arches, with other plates welded to the underside of the lower flanges. The brake cross-tube is retained not only in sturdy bearings from the frame side members, but safety, brackets are fitted from the cross-tube to comply with M.O.T. regulations. These details, together with many. finer points, show that the chassis has been designed to withstand continuous hard work, with relatively I ittle "maintenance.

The Crossley .8.6-litre six-cylindered direct injection engine has overhead valve gear which is 'driven from a camshaft located well up in the cylinder casting, and by short push-rods. A mono bloc casting of alloy cast iron,

the cylinder block is bolted to the aluminium-alloy crankcase. Air-hardened liners are fitted to the block.

Strip bearings coated with lead indium are used for all the main bearings of the crankshaft. These ensure long life and rapid dissipation of heat. Fitted with .a torsional vibration ,damper at the fore end, the crankshaft has nitrided crankpins and journals, seven bearings supporting the shaft in the crankcase. The connecting-rod•bearings are Cromet-lined on the top half to carry the load of combustion, the lower part of the bearing being lined with white 'metal. With a hardened crankshaft and this form of bearing, the need for regrinding should be infrequent.

Camshaft and auxiliaries are driven by a triplex roller chain automatically adjusted for wear by a spring-loaded sprocket, all drive sprockets being mounted on ball bearings The Clayton Dewaildre exhanster. and C.A.V. centriftrally governed fnet-injection Pump are driven by an intermediate Shaft through helical gearing. Driven by_i_.tojjc-j?..gy,§baft: is.Q61t-hr. engine, the .dynamo is

as accessibly mounted alongside the gearbox, away from the heat and vapour of the power unit.

The water pump is positively driven, a skew gear from the drive being used to operate the oil-supply pump. Oil is drawn through a strainer and delivered through an Autoklean filter to the bearings. It is then conducted through oitways to the big-end bearings. A secondary pump delivers oil to the timing chain and valve gear, and surplus oil from the valve gear is conducted through cored passageways to lubricate the camshaft bearings.

The fan is driven by twin belts and pulleys, the driving puliey being located on the front of the exhauster and fuel-pump drive shaft. As the fan is mounted on an eccentric bracket, the belts may be readily adjusted for wear.

The engine is notable for its accessibility, for all component units are mounted high above the frame line. Lifting hooks are conveniently provided on the heads, and the large orifice oil filler cap is located in line with the cylinder heads. An oil-pressure gauge is housed in the filler casting.

The engine, .clutch and gearbox unit are retained in the frame on Silentbloc mountings to isolate engine vibration, and the radiator is secured on Metalastik mountings to protect the tube stack from road shocks.

The chassis tested was fitted with a constant-mesh gearbox, although synchromesh or Turbo Transmitter units may be fitted if desired. This compact unit incorporates constant-mesh gears for second, third and fourth ratios, engagement being made through dog clutches Mounted on a bracket on the off side of the engine, the selector lever is connected by a single control to the selector mechanism housed in the gearbox cover A single dry-plate clutch unit is used, the friction plates being secured by cork inserts, so that there arc no rivet holes to collect dirt, and metal-to-metal contact is impossible Ball bearings are used to support the clutch spigot shaft, and the withdrawal mechanism is provided with a ball bearing

The propeller shaft, which is divided into two short lengths, is supported at the centre by a large bearing. A Layrub coupling is fitted to the fore part of the shaft and a Hardy-Spicer coupling is located at the rear In common with all other Crossley chassis, the tear axle is of the fully floating underslung-worm pattern; in this case the drive is offset to the near side.

Of robust design, the front axle incorporates heavyduty tapered-roller bearings for the hubs and top bearings of the swivel pins, a large plain bearing being used at the bottom of the swivel pin A cap is fitted at the bottom of the king-pin to prevent the escape of lubricating oil. All brake mechanism is enclosed, and the drums can be readily lemoved without disturbing the hubs A Clayton Dewandre triple-servo brake system is used, the rear brakes being operated from the master servo, whilst independent servos mounted direct on the stub axles operate the front brakes. Adjustment

al0 for facing wear is made independently at each wheel. Brake-camshaft and cross-shaft bearings are of generous proportions and, like the remainder of the brake mechanism, are protected against the entry of dirt or moisture.

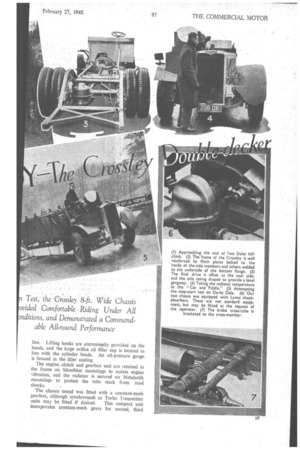

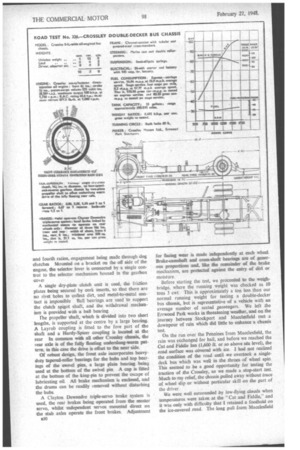

Before starting the test, we proceeded to the weighbridge, where the running weight was checked as 10 tons 3 cwt This is approximately a ton less than our normal running weight for testing a double-decker bus chassis, but is representative of a vehicle with an average number of seated passengers. We left the Errwood Park works in threatening weather, and on the journey between Stockport and Macclesfield met a downpour of rain which did little to enhance a chassis test.

On the run over the Pennines from Macclesfield, the rain was exchanged for hail, and before we reached the Cat and Fiddle Inn (1,600 ft. ors() above sea level), the road surface was covered with ice. I had not realized the condition of the road until we overtook a single deck bus which was well in the throes-of wheel spin. This seemed to be a good opportunity for testing the traction of the Crossley, so we made a stop-start test. Much to my relief, the chassis .pulled away without trace of wheel slip .or without particular skill on the part of the driver.

We were well surrounded by low-flying clouds when temperatures were taken at the "Cat and Fiddle," and it was only with difficulty that I retained a foothold on the ice-covered road. The long pull from Macclesfield had raised the radiator temperature by 22 degrees F., the final temperature being 120 degrees F. above atmospheric at this point.

With the roads in such condition, I had expected a hazardous journey on the drop down to Buxton, but found that the chassis could be driven in safety at 25-28 m.p.h It was impossible to travel faster than this because the intense hail forced me to keep my eyes almost closed, and visibility was poor It was a relief to find that Buxton was only in the midst of a heavy rainstorm, so we made a fast journey to Bakewell and Winster, in preparation for the Two Dales hill-climb between Winster and Chesterfield The climb over the Pennines might have been con sidered a sufficient *hill test for the chassis, but as it was fitted with the 6 5-to-I final-drive ratio, t considered it only fair to make the attempt on a 1-in-4 gradient Two Dales, which includes a section of this order, is two miles long and has an average gradient of 1 in 10 On the first attempt, which was Made without a stop, the Crossley climbed the hill with ease, and although we were in bottom gear, there was plenty of power to spare from the engine The second test was made under short-stage service conditions, with a stop every quarter of a mile. This caught the Crossley on the l -in-4 section at Darby Dale and we were unable to restart on this gradient After reversing to a 1-in-5 Stretch, we were able to resume the test

An Arduous Test

It was a severe trial for the well-laden double-decker, and there can be few similar conditions in this country. At the summit of the hill, the radiator temperature registered 168 degrees F, against 138 degrees F at the foot, and an atmospheric temperature of 35 degrees F

Not wishing to battle our way back Over the Pennines, we returned to Stockport by the lower road through Buxton and Whaley Bridge At Hazlegrove we turned off the direct route to make a .10-mile circuit for fuel-consumption tests on express and short-stage service For this test the Autovac supply was disconnected from the main tank. Starting with the Autovac tank filled to the point of overflowing, a volume of fuel equal to that used was measured into the tank until it was again about to overflow

In this way I gathered that on a give-and-take course, which involved a fair section of third-gear work, the Crossley could be expected to average 16.84 mpg. at

25.9 m.p.h. on express service On short-stage service of four stops to every mile, the consumption rate worked out at 8 2 m p.g and speed at 17 78 111 p.h., a 15-second stop at each point having-been deducted to arrive at this speed During the second test, we accelerated rapidly and braked sharply on every occasion These consumption figures are somewhat better than those normally yielded by a double-decker chassis, partly because of the economy of the engine, and partly on account of the lower running weight By this time the 'weather had improved and the road surface was in a fit state for brake tests With emergency applications we were able to stop in 56 ft from 30 m.p.h and 28 ft from 20 mph, espective efficiencies being 54 per cent and 48 per cent. Although.these tests were made aftef successive heavy applications of the brakes on the earlier tests, and the brakes were showing evidence of warming up, they had lost little of their efficiency As it is," the results are well suited to the requirements of a passenger vehicle Powerful Acceleration The acceleration tests which followed showed the benefit of the low axle ratio, and the results were notably good for the size of the engineemployed With accurate gear changes at 13 m.p h and 20 in.p.h , the Chassis reached 20 m.p.h from rest in 11,5 secs and 30 mph. in 25 secs Top-gear acceleration was correspondingly good and from 10 to 20 m p h was'aChieved in 11 secs

and to 30 m.p.h in 245 secs • After a short journey back tri the works, the lubricating-oil temperatures showed the engine oil to be 136 degrees F and the real axle 155 degrees F These results ale highly satisfactory, when taking into consideration the fact that the last 12 miles had been covered under the heavy load conditions of stopping and starting every 500 yds.. and the atmospheric temperature had risen to 46 degrees F When driving the Crossley, I appreciated the convenient positions and light action of the controls Moreover, the engine induction roar was well toned down by the efficient air silencer' • With the 6 5-to-1 linal-drive ratio, the chassis is well suited to short-service operation, and can he expected to hold its own against others with high engine capacity and high axle ratios With the alternative ratio of 6 to 1, it should be admirable for express service, and an economical performance could be expected.