BRAKES AND CLUTCHES.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Hints and Tips from Our Driver and Mechanic Readers.

THE 15e. ,prize is awarded this week to "E.B.," of Woking, for his ingenious yet extremely simple tip for increasing the life of socket or jaw brake-rod ends. In hia letter, he refers to the trouble which his idea is intended to eradicate, as occurring in connection, with one special type of vehicle, and he, obviously, has considered it in connection with brake coupling rods only. As a matter of fact, however, it is universally applicable in, a double sense, inasmuch as there are few cars to which it is net, in some way or other, useful, whilst it may be found to be adaptable to steering gear rods, radius rods, and many other parts of the chassis mechanism.

At least, however, we may relate the story, if not quite in his own words. He experienced, lie tells us, rather rapid wear of the screwed jaw ends of the brake rods on his car, the said screwed ends being designed so that, by screwing them up on the rod, adjustment of the length of that same rod could be readily effected. -Unfortunately, after a time the thread wore out, so that the rod would slide up and down inside the

ja end, which was, therefore, to all int ts and purposes, practically useles , and it almost appeared that new

impwere the inevitable solution. e avoided the expense which such re ewal would have entailed, however, by the following expedient. He rem ved the jaw ends and screwed them on the outside, On. Whitworth, with a ta ering thread. He then saw-cut the lx s of the jaw, as shown in the sk tch. The rest needs little explana ti In replacing the rods, the nut on th outside of the jaw was first just st rted net its thread, in which position it squeezes the internal thread suffie ently to ensure its biting on the th sad on the rod. The length of the ro is then carefully adjusted as req red by the conditions of the re

mainder of the brake parts, and the outer nut finally screwed up the taper thread until it is tight, when it locks the rod and jaw end firmly in position, making, as a matter of fact, a better job than would have been achieved by the replacement of those ends.

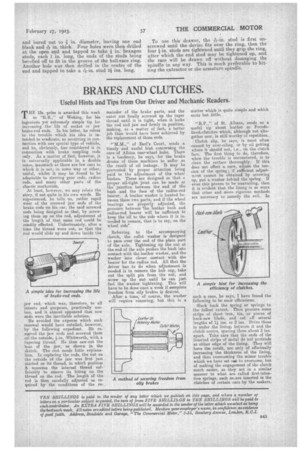

"M.M.," of Earl's Court, sends a timely and useful hint concerning the care of Albion rear-wheel hubs. There is a tendency, he says, • for the brake drums of these machines to suffer as the result of oil leakage. It may be prevented by proper attention being paid to the adjustment of the whee! bushes. These are designed so that a proper oil-tight joint can be made at the junction between the end of the bush and the face of the radius-rod bearer. A leather washer is located between these two parts, and if the wheel bearings are properly adjusted, the pressure between 'the leather bush and radius-rod bearer will be sufficient to , keep the oil to the side where it is intended to remain, that is to say, on the wheel side' Referring to the accompanying sketch, the collet washer is designed to pass over the end of the plain part of the axle. Tightening up the nut at the end of the axle pushes the bush into contact with the leather washer, and the washer into closer contact with the bearer for the radius rod. All that the driver has to do when adjustment is needed is to remove the hub cap, take out the split pin from. the nut, and screw up the nut until he can just feel the washer tightening. This will have to be done once a week if eemplete freedom from oily brakes is desired. After a time, of course, the washer will require renewing, but this is a matter which is quite simple and which costs but little.

"R.P.," of St. Albans, sends us a useful tip about leather or Ferodolined,clutches which, although not alto.gether new, is still worthy of repetition.

Clutch slip, he says, is most often caused by over-oiling, or by oil getting where it should not, i.e., on the clutch face. The first thing to do, therefore, when the trouble is encountered, is to clean the surface thoroughly. If this does not effect a. cure, adjust the tension of the spring; if sufficient adjustment cannot be obtained by screwing up, put a washer behind the spring. If even this proves to be unavailing, then it is evident that the lining is eo worn that other and more rigorous methods are necessary to remedy the evil. In such a case, he says, I have found the following to be most efficacious.

Slack back the spring or springs to thefullest extent. Then procure some strips of sheet iron tin, -or pieces of hack-saw blade, and cut off several lengths of II ins. or 2 ins. Drive these in under the lining, between it and the clutch centre, spacing them about 3 ins. apart. Take care that the ends of the inserted strips of metal do not protrude at either edge of the lining. They will have the result, not only of effectually increasing the thickness of the lining, and thus overcoming the minor trouble which we have set mat to overcome, but of making the engagement of the clutch much easier, as they act in a similar manner to what are called first-intention springs, such as.are inserted in the clutches of certain cars by the makers.