HINTS ON MAINTENANCE.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

338.—Setting-up the Foden Front Axle.

After a Foden wagon has been running for some years it will occasionally be noticed that the front axle appears to lean under the boiler. Various methods of overcoming, or attempting to overcome, this trouble have been devised. In some cases the axle has been taken out and turned round, but this

does not effect an improvement, as the fault is usually due to wear on the turntable.

This can be rectified by the use of a special phosphor-bronze washer made thicker at one side than at the other—in other words, wedge-shaped.

Two small holes are ugnally provided in the lower half of the turntable ; if not, suitable holes can be drilled. They should be tapped out I in. for a depth of fn., taking care not to go right down to the bottom, as otherwise it may render the removal of the spring bolt very difficult when the necessity to perform this operation arises. The washer must also be drilled and tapped for the two setscrews which are used for fastening the washer. After inserting these, saw off the heads and rivet over, finishing off to a smooth surface by the use of a file.

When fitting the washer, it will be necessary to adjust the cotter pin at the top of the pivot.

339.—Notes on the Dorman Engine.

The valve guides on the Dorman engine are renewable, and are made of good-quality cast-iron. In the event of the guides becoming badly worn, they can be removed by means of a drawing tool, or driven out, if tare be used in the latter operation. En turning a new set it is advisable to bore them a little over a running fit to allow for heat expansion, which might otherwise result in the valves sticking.

The tappets and tappet guides can easily be removed for inspection or renewal. Sometimes the small pin on which the tappet rol'er revolves wears or becomes loose, or a portion of the roller face may break away and set up an objectionable knock which may possibly be attributed to excessive clearance between the valves and the tappets

If at any time the inlet pipe has to be removed, B42 great care should be taken when it is being replaced, for the reason that the casting is divided, the top portion forming the connection between the two cylinders for the circulating water, whilst the lower half carries the mixture, and if a good joint is not secured the water may find its way into the inlet duct, causing a spluttering misfire while the engine

is running. •

On some of the Caledon chassis the inlet pipe is difficult to remove owing to the insufficient clearance allowed between the casting and the steering column, so that the casting cannot be withdrawn from the studs. If this be found to be the case, a cure can be effected by riveting the nuts on to the two studs nearest the dash, thus turning them into setscrews. The fan bracket also acts as an engine oil filler, and at its base is a strainer which requires cleaning from time to time. To do this it is necessary to remove the bracket and the fan, but this only entails the removal of four bolts, the out2r edges of the strainer forming the joint.

340.—Easing a Fierce Clutch.

One of our contributors states that some time ago he experienced difficulty with a cone clutch faced with a bonded asbestos material, this clutch being rather too fierce to be comfortable. He tried many .methods in order to effect an improvement, such as drilling holes and inserting corks, putting small springs under the material, etc. Some of these proved fairly effective for a short time, but did not last long enough to make's n appreciable difference.

He finally had a groove turned in the face of the Clutch cone, this groove being in. wide and deep. Into this groove he inserted a piece of catapult elastic and replaced the friction material. Since this time he has used the clutch for two years with very successful results,

341.—Withdrawing Magneto Ball Races.

We recently published a description of a device for removing the inner ring of a magneto ball race. One of our correspondents has forwarded particulars of what he considers is a better extractor, which has the advantage that there is no need to knock the end of the' spindle in order to remove the race.

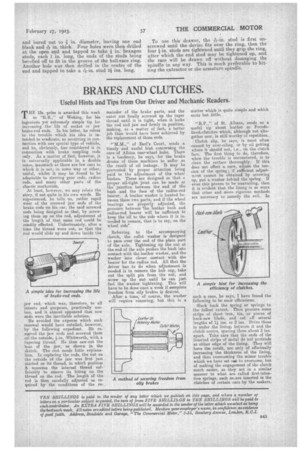

The instrument was made from a piece of round steel, 21 ins, long, which was put in the lathe

and bored out to in. diameter, leaving one end blank and'IT in. thick. Four holes were then drilled at the open end and tapped to take in. hexagon studs, each 1 in. long, the ends of the studs being bevelled off to fit in the groove of the ball-race ring. Another hole was then drilled in the centre of the end and tapped to take a k-in. stud 211 ins. long. To use this drawer, the A-in. stud is ,first unscrewed until the device fits over the ring, then the four }-in. studs are tightened until they grip the ring, after which the end stud may be tightened up, and. the race will be drawn otT without damaging the spindle in any way. This is Much Preferable to hitting the extractor or the armature spindle.