Five EuroStar models for OR

Page 32

Page 33

Page 34

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

by Toby Clark

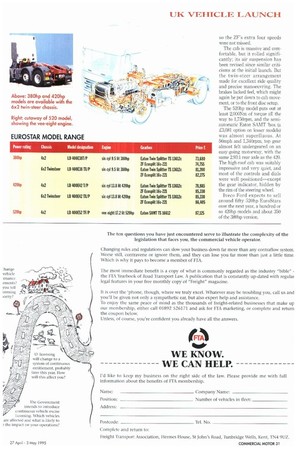

• Iveco's long-awaited EuroStar has finally made it to the UK, with five models at three power ratings from 380hp to 520hp, three roof heights and a choice of ZF or Eaton gearboxes. Base prices range from £73,680 to £87,125.

Launched to Europe's press almost two years ago, the EuroStar has been confined to the Continent while UK dealers got to grips with EuroTech, the mainstay of Iveco Ford's heavy range.

But in a rising heavy vehicle market, Iveco Ford Marketing Director Chris Christianson expects to sell 300-500 EuroStars in the first year (against 1,300-1,500 EuroTechs), mainly to owner-drivers and international haulage contractors with multiple-night trips.

The five basic models available in the UK comprise 4x2 (T/P) and 6x2 twin-steer (TX/P) variants of the 380hp and 420hp models—each has rear air suspension, and an Eaton Twin Splitter or a ZF Ecosplit 'box— and the SAMT-equipped 520hp model on a fully air-suspended 4x2 (TF/P) chassis.

The Ulm-built EuroStar's Iveco engines are the electronically controlled 375hp (276kW) 9.5-litre six-cylinder unit, the 420hp (309kW) 13.8-litre six and the 514hp (378kW) 17.2-litre vee-eight—the smaller two are already fitted to the EuroTech, which shares its chassis with the EuroStar. A 470hp version may be introduced once the specifications for Euro-3 are finalised.

The UK EuroStar is called the LD400E, indicating a plated GCW of 40 tonnes—the design GCW of 44 tonnes is shown by the Continental model designation of LD440E.

The medium-height cab, seen this year in CM's Sleeper Cab Test (CM 9-15 March), is standard: low or high-roof cabs are optional, the tallest has a maximum internal height of 2.37m. All have three-zone air-conditioning: the driver simply sets the desired temperature for each zone. A night heater is standard on the 520hp model. A lifting pusher axle (on the standard 3.80m outer axle spread) will be a Special Product Option (SPO) costing £6,800.

DRIVING IMPRESSIONS

CM first drove the 420hp EuroStar fitted with the 12speed Twin Splitter gearbox; this installation worked well, allowing for fast changes, and the engine had sufficient torque to stay happily in 11th on A. roads. It was easy to keep the revs in the "double green" band, so the ZF's extra four speeds were not missed.

The cab is massive and comfortable, but it rolled significantly; its air suspension has been revised since similar criticisms at the initial launch. But the twin-steer arrangement made for excellent ride quality and precise manoeuvring. The brakes lacked feel, which might again be put down to cab movement, or to the front disc setup.

The 520hp model puts out at least 2,000Nm of torque all the way to 1,750rpm, and the semiautomatic Eaton SAMT 'box (a

3,081 option on lesser models) was almost superfluous. At 56mph and 1,340rpm, top gear almost felt undergeared on an easy-going motorway, with the same 2.93:1 rear axle as the 420. The high-roof cab was suitably impressive and very quiet, and most of the controls and dials were well positioned—except the gear indicator, hidden by the rim of the steering wheel.

Iveco Ford expects to sell around fifty 520hp EuroStars over the next year, a hundred or so 420hp models and about 350 of the 380hp version.

Cab suspension

The old two-point rear cab suspension, with front eccentric rubber bushes, has been replaced by a four-point coil sprung system.

At the front the coil spring and damper units are linked with a heavy-duty torsion bar to counter roll. The cab's rear suspension has effectively been turned on its head: previously the dampers were mounted on the cab with the locking catch on the frame; the new model has the dampers on the frame and the locking catch on the cab, making lock-down easier.

Cab exterior

The cab floor is now a one-piece composite construction; with redesigned steps to make entry easier and safer. The front frame has also been revised, reducing the front overhang by 75mm.

There are separate brackets for the cab, towing eye and front spring mountings (all three were previously attached to a large one-piece cast aluminium bracket which doubled as the front cross member receiver). Beneath the grille is a new bumper and air dam. Although it is moulded in one piece, it can be replaced in sections and Foden will produce separate ends, allowing easy repairs to corner damage. The end sections can simply be cut off and the replacements bolted in place. The front cab corners have been made smoother and more aerodynamic.

Foden's new 4000 Series cab sits higher than its predecessor to make room for extra noise encapsulation. This helps it meet the 80dB(A) drive-by noise limit which comes into force for new vehicles from 1 October 1996. The "low datum" cab sits 20mm higher than before; the "high datum" version (which sits on top of the Cummins 14litre) is 50mm higher. Both variants have extra door skirts.

The traditional Foden ram air intake protruding above the cab has been dropped in favour of a neat intake on the rear offside. The filter itself now lives under the cab; the locker behind the driver's seat has been lost as a result. According to Foden's senior project engineer Reg Lewis, the task is not to force air in, but to place the intake in an area of cool, relatively undisturbed air, "The only place you can realistically put it is where we've got it now", he says.

Foden has used its transatlantic connection to good effect—the new cab steps and rear catwalk are based on standard Kenworth walkway sections with large holes that prevent dirt build-up.

Traditionalists will welcome the return of the kite to the Foden grille; it is also destined to reappear on the smaller 2000 and 3000 Series cabs.

Other exterior changes include the grouping together of all major electrical and air connections under the lifting grille, 110. beneath a separate weatherproof cover. Access should be better than with their previous location inside the cab.

The optional under-cab mounting point for batteries has been deleted as this space is now taken up with an air tank and integral air dryer.

At the rear of the cab, the revised catwalk and grab handle improves access for coupling up.

New moulding techniques While Foden continues to rely on traditional open-faced moulding methods when building up its cabs, the new 4000 Series' one-piece floor pan, front bumper and air dam, step surrounds and mud wings are produced using a technique called Resin Transfer Moulding (RTM).

Components are produced by placing glass fibre strands into a heated, closed mould which then has resin injected into it. This is said to give a more consistently finished panel, with smoother, more attractive surfaces.

All the new mouldings are sourced from an outside supplier and such is the quality of the RIM components that it is easy to mistake them for plastic constructions. Cab interior changes The new 1000's interior has received a lot of attention; ironically, it now resembles that of the EC from Sandbach rival. ERF. The redesigned dashboard, described by general marketing manager Gary Rowlands as "less of a curve, more of a dogleg" puts everything within easy reach and space is made for Cummins' Road Relay on-board trip computer display.

The heater controls are smoother to operate and extra vents in the dash direct air to the driver's face. The whole heater system has been upgrad ed a new radiator header tank ensures that the system is more tolerant of any coolant loss.

There is a smaller more attractive steering wheel and new padded door trims from Paccar. Subtle changes are designed to improve the driving position: the brake pedal has been lowered on all models and those equipped with the new Eaton S-Series gearbox will have a lower mounted clutch pedal. Steering column adjustment should be better, thanks to a mechanism that is easier to release. The steering downshaft is also new, Floor or seatmounted seatbelts can be ordered as an option.

Small detail fittings include a shaver socket and mirror, and fold out drink tray over the central engine hump which has a different covering.

Our first impression of the pre-production sleeper cab is that it will be an attractive home-from-home that maintains the Foden tradition of a cab that's comfortable yet practical. Swivelling eyeball-type interior lights are used in place of the previous fixed lamps and the striped seat trim has been superseded by a single colour.

The bunk in the standard Milne sleeper cab has been raised by 250mm giving much more usable storage space beneath it. The mattress and base are supported on gas filled struts and split into two sections to ease access to the storage compart. ments. To utilise that storage space Foden fits the night heater under the passenger seat.

A neat roller blind blanks out the optional rear window and new, heavier curtains extend round the track easily and stow away with the minimum of fuss.

Chassis The shorter front overhang has reduced the swept turning circles. Foden has also specified ZF Servocom 8098 steering gear for the new 4000 and is now able to rate the front axle at 8,000kg without recourse to a booster rain.

Standard suspension will continue to be front steel parabolics, with air suspension as an option, with or without ECAS on the rear. Disc brakes will not feature on the new 4000 at the moment—but Foden is running a separate project for disc brake developments. The changes to the new 4000 have increased the tare weight by some 100kg.

Drivetrain

Last summer, Foden announced that it would be the first UK truck maker to offer Cummins' 11litre M11 engine—its TipCon appearance in the new 4000 fulfils that promise. The M11 will fit under the "low datum" cab Rowlands says: When we launch this vehicle we'll be launching a new drivetrain as well. Operators will be able to place an Mll order immediately for July supply."

The M11 will initially be offered at a nominal 374hp (279kW) with 1,3501bft (1,825Nm) of torque. A 335hp (250kW) version is in the pipeline. While interest in Mil is likely to be high, the familiar L10 engine will stay on line until the Euro-2 deadline in October 1996.

Although Perkins has lost a lot of the ground it made against Cummins in the early nineties Foden is sticking with the 12-litre Tx. The Euro-2 Tx also makes its debut at TipCon this week (see TipCon report for full details). The straight-six Perkins will be able to meet the tough Euro-2 emission barrier "without electronics", says Rowlands.

Fans of the famous yellow Caterpillar engine range can take heart from Rowland's comment that Foden "has firm plans for the Cat...they are on the horizon, but the timing for Cat engines has yet to be finalised." Commercial Motor expects Foden to offer the 10-litre, electronically con trolled 3176 Caterpillar and the 500hp 14-litre 3406E. Given the cost of certificating both engines to Euro-1, only to recertificate them for Euro-2 within 18 months, Foden might well go straight to Euro-2 versions in time for October 1996. It has no plans to offer a Detroit Diesel 60 Series.

Along with the Mll diesel the TipCon show truck will also have the latest S Series Eaton synchro box, operated by the traditional Foden cable linkage. This box will not replace the TwinSplitter but will be offered alongside the constant-mesh Eaton boxes. Allison's fivespeed World Series automatic box will also be on the extensive options list.

Project history The new 4000 Series is codenamed 5-10—the fifth variant of the long-serving S10 cab. It has its roots in a project to fit fourpoint cab suspension in 1990. Foden's marketing, sales and engineering departments were involved in the design team and it was soon realised that fitting four-point cab suspension would entail other changes to the cab's front.

During 1991 and 1992 a number of 4000 Series cabs were built with four-point cab sus pension. Various changes were experimented with and prototype testing began in 1993. That year Foden invited its first 'customer focus group', made up of fleet customers, to view the new 4000 Series at Sandbach. Dealer focus groups followed.

In 1994 the first prototypes were shipped to the US for durability testing at the Paccar proving ground at Mount Vernon, Washington State. The plan was to launch the vehicle last summer, but following the durability tests the launch was put on hold. The new 4000 Series was rigorously tested and in the process, the test team cracked a front cross-member, something Foden has never managed before, Severe corrosion testing also triggered some re-design work. Although Foden was confident that the product could be launched as it stood, the company believed it was worth delaying to see the revisions into production first.

Marketing story The changes will be carried over to Foden's 3000 and 2000 Series trucks later this year. They are designed to attract new customers in the fiercely contested fleet market, the construction industry and the North-West of England. Tractive units account for some 55% of the UK heavy truck market, but only 21% of Foden's output. If the company is to improve its UK market share from around 3%, it will have to improve its market penetration for tractive units.

The adoption of the S Series will allow Foden to compete against Continental manufacturers in the lucrative rental and contract hire fleets, where driver acceptance of constantmesh transmissions is low.

Foden will focus on UK sales with the 4000. Rowland says: "We will probably have to upgrade our dealer network to meet the targets." The company has 54 UK service points.

The new 4000 Series will cost around £1,000 more than the current model. Development continues—Rowlands promises significant changes in the next twelve months.