More Power to the Chieftain's

Page 58

Page 59

Page 60

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Use of more powerful engine i Chieftain Super Six results in Ili formance whilst still retaini operational econo By John F. Moon, A.M.I.R.T.E.

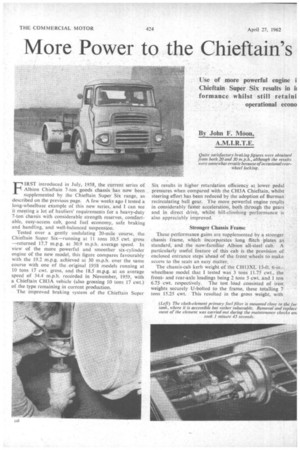

FIRST introduced in July, 1958, the current series of Albion Chieftain 7-ton goods chassis has now been supplemented by the Chieftain Super Six range, as described on the previous page. A few weeks ago (tested a long-wheelbase example of this new series, and I can see it meeting a lot of hauliers' requirements for a heavy-duty 7-ton chassis with considerable strength reserves, comfortable, easy-access cab, good fuel economy, safe braking and handling, and well-balanced suspension.

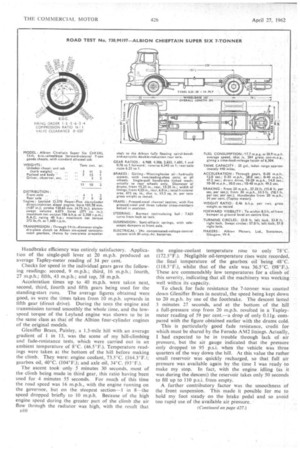

Tested over a gently undulating 20-mile course, the Chieftain Super Six—running at 11 tons 10.5 cwt. gross —returned 17.7 m.p.g. at 30.9 m.P.h. average speed. In view of the more powerful and smoother six-cylinder engine of the new model, this figure compares favourably with the 19.2 m.p.g. achieved at 30 m.p.h. over the same course with one of the original 1958 models running at 10 tons 17 cwt. gross, and the 18.5 m.p.g. at an average speed of 34.4 m.p.h. recorded in November, 1959, with a Chieftain CH3A vehicle (also grossing 10 tons 17 cwt.) of the type remaining in current production.

The improved braking system of the Chieftain Super Six results in higher retardation efficiency at lower pedal pressures when compared with the CH3A Chieftain, whilst steering effort has been reduced by the adoption of Burman recirculating ball gear. The more powerful engine respIts in considerably faster acceleration, both through the gears and in direct drive, whilst hill-climbing performance is also appreciably improved.

Stronger Chassis Frame These performance gains are supplemented by a stronger chassis frame, which incorporates long flitch Plates as standard, and the now-familiar Albion all-steel cab. A particularly useful feature of this cab is the provision of enclosed entrance steps ahead of the front wheels to make access to the seats an easy matter.

The chassis-cab kerb weight of the CH13XL 13-ft. 6-in.wheelbase model that I tested was 3 tons 11.75 cwt., the frontand rear-axle loadings being 2 tons 5 cwt. and I ton 6.75 cwt. respectively. The test load consisted of iron weights securely U-bolted to the frame, these totalling 7 tons 15.25 cwt. This resulted in the gross weight, with

nobody in the cab, exceeding the Albion recommended figure by 5 cwt., but even so it is obvious that use of a heavy timber-construction platform body would still permit a 7-ton payload to be carried on this chassis without exceeding the stipulated 11 tons 2 cwt. limitation.

With myself and Albion's " Borizo " Storti aboard, the 7-tonner grossed 11 tons 10.5 cwt., and of the total imposed load the front wheels were carrying 4 tons 1.5 cwt., whilst the rear axle's share of the load was 7 tons 9 cwt.

Gradient restart tests were carried out on the way north out of Glasgow, on the 1-in-5 Murrayfield Drive. Westerton. Facing up this gradient the handbrake held the vehicle easily with a single-handed pull and without need for assistance from the footbrake. An attempted restart in second gear only just failed, but a bottom-gear restart was •made very easily, using only about a quarter of the available throttle travel.

The Chieftain Super Six was then turned around and a

stop was made facing down the hill. Again the handbrake held the machine quite comfortably, but, because of the higher reverse ratio, slightly more throttle opening was required when making a reverse restart, and even then I found it difficult to get away smoothly. A certain amount of transmission judder was evident.

Continuing north, the Albion was taken to Buchlyvie. Here the fuel-test tank was connected to the fuel system, following which a 10-mile consumption test in the direction of Stirling was carried out. The first five miles of this course are sharply undulating. The second half of the stretch is almost completely flat, but despite this the road speed was kept down to about 33 m.p.h. throughout.

Gross Ton-m.p.g. Values

Following braking and acceleration tests, this 10-mile stretch was retraced back to Buchlyvie, and the quoted fuel-consumption figure of 17.7 m.p.g. is based on the total amount of fuel used for both legs of the test. It is interesting to note that, although the consumption rate is slightly heavier than that of the two earlier Chieftain models, the gross ton-m.p.g. figure of 204 compares closely with that of 217 obtained with the 1959 CH3A and 209 produced by the CH3 tested in 1958.

Between this two-part consumption test, acceleration and braking trials were carried out on the long, flat, straight stretch of road to the west of Stirling. Quite satisfactory braking figures were obtained at full pedal effort from both 20 and 30 m.p.h., although the results obtained were some what erratic because of irregular rear-wheel locking. Several stops were made without any rear-wheel locking at all, however, and under these conditions the Albion came to rest in an average distance of 53.5 ft. from 30 m.p.h. and in 27.75 ft. from 20 m.p.h.

It seems clear that this Girling-Westinghouse airhydraulic braking system is fairly finely tuned, and that the rear brakes are intended to bring the rear wheels just to the point of locking. The result is that slight variations in road surface can cause the brakes to lock the wheels completely. Probably a little less effort at the rear brakes would reduce this tendency. There was very little lag detectable in the system, but I still feel that were the front brakes taking a higher share of the overall braking effort the stopping distances could be reduced by some 5 ft. or so. Handbrake efficiency was entirely satisfactory. Application of the single-pull lever at 20 m.p.h. produced an average Tapley-meter reading of 34 per cent.

Checks for speed in the individual gears gave the following readings: second, 9 m.p.h.; third, 16 m.p.h.; fourth, 27 m.p.h.; fifth, 43 m.p.h.; and top, 58 m.p.h.

Acceleration times up to 40 m.p.h. were taken next, second, third, fourth and fifth gears being used for the standing-start runs. The average figures obtained were good, as were the times taken from 10 m.p.h. upwards in fifth gear (direct drive). During the tests the engine and transmission turned smoothly the whole time, and the lowspeed torque of the Leyland engine was shown to be in the same class as that of the Albion four-cylinder engines of the original models.

Gleniffer Braes, Paisley, a 1.3-mile hill with an average gradient of 1 in 13, was the scene of my hill-climbing and fade-resistance tests, which were carried out in an ambient temperature of 8°C. (46.5°F.). Temperature readings were taken at the bottom of the hill before making the climb. They were: engine coolant,73.5°C. (164.3°F.); gearbox oil, 40°C. (104°F.); and axle oil, 34°C. (93°F.).

The ascent took • only 5 minutes 30 seconds, most of the climb being made in third gear, this ratio having been used for 4 minutes 55 seconds. For much of this time the road speed was 16 m.p.h., with the engine running on the governor, but on the steepest section-1 in 8-the speed dropped briefly to 10 m.p.h. Because of the high engine speed during the greater part of the climb the air flow through the radiator was high, with the result that

the engine-coolant temperature rose to only 78°C. (172.5°F.). Negligible oil-temperature rises were recorded, the final temperature of the gearbox oil being 48°C. (118.5°F.), whilst that of the axle was 36.5°C. (98°F.). These are commendably low temperatures for a climb of this severity, indicating that all the machinery was working well within its capacity.

To check for fade resistance the 7-tonner was coasted down Gleniffer Braes in neutral, the speed being kept down to 20 m.p.h. by use of the footbrake. The descent lasted 3 minutes 27 seconds, and at the bottom of the hill a full-pressure stop from 20 m.p.h. resulted in a Tapleymeter reading of 59 per cent.-a drop of only 0.11g. compared with the figure obtained earlier with the drums cold.

This is particularly good fade resistance, credit for which must be shared by the Ferodo AM2 linings. Actually, I had expected to be in trouble through lack of air pressure, but the air gauge indicated that the pressure only dropped to 95 p,s.i. when the vehicle was three quarters of the way down the hill. At this value the rather small reservoir was quickly recharged, so that full air pressure was available again by the time I was ready to make my stop. In fact, with the engine idling (as it was during the descent) the reservoir takes only 50 seconds to fill up to 110 p.s.i. from empty.

A further contributory factor was the smoothness of the front suspension. This made it possible for me to hold my foot steady on the brake pedal and so avoid too rapid use of the available air pressure. The Chieftain Super Six has front springs with a higher rate than those of the Chieftain CH3A, and I consider that these give a better cab. ride than is obtainable in the lighter vehicle. The Super Six rides, extremely well under all conditions and, with_the improved steering characteristics, this makes it a very pleasant vehicle to handle.

The variable-ratio Burman gear steering requires only light efforts when approaching full lock at walking pace, whilst towards the dead-ahead position there is a noticeable increase in the effort required, although this never gets to the point of being heavy. Castor action when running forward is pleasant, although not pronounced, but when moving in reverse the self-centering action becomes, if anything, "negative," so that it is difficult to get off full lock when reversing in a confined space.

Brake-pedal effort, reaction to which is provided by a coil spring, is low, and the braking characteristics are progressive. The action of the clutch is also light, only about 55 lb. being required for complete disengagement, whilst the action of the gear change is, as usual with this Albion unit, above reproach.

Engine-noise insulation The test vehicle was basically standard except for the optional overdrive ratio, the pressed-steel front bumper and the spare wheel and carrier, but a further piece of optional equipment was a quilted muff over the engine cowl This is a comparatively cheap item, but one which I feel could well be standard because its sound-insulation properties proved to be very high so that engine noise in the cab was not particularly great. With the quilt off, however, considerable mechanical, injection and induction noise penetrated the standard steel cowl, and I feel that it is a case of spoiling the ship for a ha'porth of tar to supply the Chieftain Super Six without a bonnet cover as standard.

The finish of the standard cab is generally quite satisfactory, although the draught proofing of the example I had was not particularly brilliant. Some of the draughts came in through the glove boxes, of all places. Furthermore, when the optional heating and demisting equipment is not fitted (as in the case of my cab) penetrating draughts tear at the driver's and passenger's feet through two holes in the frontal panelling. Simple cover plates over these openings would solve this problem when heating units are not fitted.

Although the standard rear-view mirrors have a nominal diameter of only 5 in.. they are Eversure convex mirrors and the range of vision they give is almost as effective as that provided by quite large, flat mirrors, which would, in any case, be more expensive, more difficult to mount rigidly and more liable to create forward and sideways blind spots.

Various maintenance tasks were conducted on the Chieftain Super Six, the first of these being level checks.

was able to check the coolant level in 10 seconds, engine oil in 28 seconds, gearbox oil in 52 seconds and the rearaxle oil in 1 minute 9 seconds. There is a trap in the cab floorboard on the passenger side to give access to the dipstick, whilst the level plugs in the gearbox and axle

both have the same size of head, a B.S.F. spanner being required.

The reservoir for the braking-system hydraulic fluid is located ahead of the radiator, access to it being provided by pulling forward the radiator grille which is secured by two budget locks. This procedure took me only 38 seconds. There is a separate reservoir for the clutch

hydraulic circuit, and the level in this took me 2 minutes 30 seconds to check, access to the reservoir being obtained through a two-bolt trap in the driver's floor board—and the reservoir cap itself being protected by a rubber cap which is not easy to replace, although undoubtedly useful.

Battery-level checks were complicated by the seat mounting arrangement. There is a battery under each of the cab seats, and the complete seat assemblies have to be removed before the cell levels can be seen,. The scat frames incorporate four pegs which fit tightly into four rubber bushes,,and a crowbar is needed to ease each seat out of its mounting. My times for checking the levels in the two batteries were 1 minute 30 seconds for the nearside, and 2 minutes for the off-side, but these times exclude the minutes spent in looking for and using the crowbar. In any case, I do not like the adjustment method of the driving seat, it being quite impossible to re-position the seat while sitting on it.

Air-cleaner Oil Level To get at the oil-bath air cleaner it is necessary to remove the single engine-cowl panel, this taking 12 seconds. With the panel off, the cleaner level can be checked in 1 minute 15 seconds, replacement of the cowl panel taking a further 18 seconds. While the cowl was off I removed and replaced the element of the C.A.V. bowl-less fuel filter in 1 minute 10 seconds, but did not attempt to remove an injector, the procedure involved being somewhat cornplicated.

The primary fuel filter is of the cloth-element type, and removal and replacement of this clement took me 1 minute 45 seconds, although I got soaked with dery in the process, because the filter is below the level of the fuel tank and therefore, when it is stripped, fuel syphons vigorously from the tank. In addition to this disadvantage, the very location of the filter itself renders it liable to damage if the vehicle is taken over very rough ground.

I did not adjust the brakes, change a fuse or remove the spare wheel of the test chassis, but the times for these tasks should be the same as for the CH3 Chieftain tested in 1958. On that occasion I adjusted the brakes in a total time of 8 minutes 15 seconds, changed a fuse wire in 5 minutes 15 seconds and removed the spare wheel in 4 minutes, re-stowage taking a further 5 minutes. The design of the spare wheel carrier is not altogether satisfactory, for it is necessary to get underneath the carrier to reach the four securing nuts.

The Albion Chieftain Super Six CH13XL 13-ft. 6-in.wheelbase chassis, with standard cab, is listed at 11,837.