Rapid Acceleration and Good akes

Page 30

Page 31

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

Mark the

w Volvo

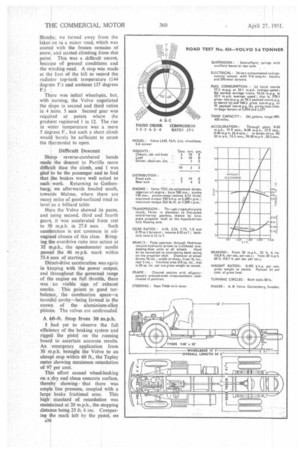

By L. J. COTTON, AN acceleration rate , of .' over 1 m.p.h. per second to 30 m.p.h. and efficient braking after five miles' continuous "burning'• were highlights in the performance of the new Volvo 5-6tonner which I tested in Sweden This model, powered by a new direct-injection off engine, is, like its predecessors, built for hard work

This is shown in the robust assembly of the chassis, the adequatesized components and its unladen weight: in stripped form it tips the scales at 3 tons 7 cwt. There was sufficient evidence in the experimental and design departments to convince me that although reduction of weight is considered important, it is secondary to soundness of construction Formerly the Volvo goods chassis was available only with a pre combustion-type power unit and this engine, from the cylinder block downwards, forms the basis of the direct-injection oil engine. Conforming with current design, it has a monobloc cast-iron crankcase and cylinder block and a Tocco-hardened seven-bearing crankshaft, which rotates in precision-finished steelshell lead-bronze-coated bearings. The bearing journals are of large diameter, and the connecting rods are split obliquely across the bores for withdrawal through the cylinder block

Lubrication System

Pressure lubrication is supplied to all bearings, valve gear, timing gears and the gudgeon pins. Oil is drawn through a floating screen and pumped through a rotatable selfcleaning filter actuated by the clutch pedal. This filter is of the laminatedsteel pattern.

Wet-type cylinder liners are employed, the upper seal being made by the head gasket, whilst two washers at the periphery form a seal at the base of the block The camshaft And auxiliaries are operated from the crankshaft by, a gear train, and the dynamo and fan. share a common .lielt.and pulley drive from the front of_the crankshaft

The C.A.V. fuel-injection equipt28 ment, with vacuum-governor control. is mounted on the right-hand side of the cylinder casting, and delivers fuel to low-pressure four-hole injectors. with an opening pressure of 120 atmospheres.

This direct-injection unit, designed and built by ' Volvo in its Penta Works, has a maximum output of 100 b.h.p. at 2,400 r.p.m. when complete with accessories, and a torque of 253 lb.-ft. It is rather more powerful than the average engine fitted to a British-made vehicle of the same load capacity, and affords a power-to-weight ratio of approximately 0.5 b.h.p. per cwt with full load. Thus, the performance is above average in respect of hillclimbing and acceleration.

The Borg and Beck 14-in.-diameter clutch, with spring centre plate, is of adequate size for the high torque, and the five-speed overdrive-top gearbox, with a cast-iron case, is again of generous proportions. This unit, made by one of the Volvo subsidiary companies, has synchromesh engagement for all gears except the lowest ratio, and a helical tooth form

• is provided for the second, third, fourth and overdrive gears. Some of the latest Gleason machines are emplo.yed for accurate cutting of the gear blanks.

The fully floating rear axle is provided with a hypoid final drive, the standard ratio of 6.33 to 1 being used in conjunction with 9.00 by 20-in. tyres, giving a maximum speed of over 50 m.p.h. A Hardy Spicer two-piece propeller shaft with a flexibly mounted centre bearing, conveys the drive from the gearbox to the axle.

Frame Construction The chassis frame is a pressed-steel channel-section structure, assembled by cold riveting. The alligator-jaw, cross-members are formed by joining two top-hat-section pressings at their flanges, and the extremities of each member are made to add to the resistance to lozenging. The fuel and vaccum tanks, battery crate and cab running-boards are supported on outriggers from the side members.

In keeping with the power-toweight ratio, the brake frictional area is high. The Volvo has 16-in.-diameter drums and wide shoes, which afford a total frictional area of 518 sq. ins., or approximately 50 sq. ins.per ton with full load. In addition. there is an independent contracting •band on the transmission system for. use when parking or'. ii an emergency.

The main system incorporates a ydrovac, with a vacuum cylinder of i-in. diameter, and a Lockheed ave cylinder H ins, in diameter and /0-leading-shoe units at the wheels.

the Hydrovac unit, the piston is tamed in the " off " position by a ispended vacuum, which is !strayed to apply the brakes. The rums are made of heavy-section ist iron reinforced with cooling is.

Gothenburg, the birthplace of the st vehicle, is in flat country, and a difficulty was experienced in eating suitable ground for acceleraan and braking trials. Rather more ire was required to find a hill to imb, although with the aid of an :.dnance map, a road was found ading up to a range of hills about ! miles away.

The 5}-ton payload was added !fore leaving the works, and the eighbridge record revealed that 29 per cent, of the gross load was carried by the front axle. With a normal-control chassis, such as the Volvo, it is difficult to achieve a load ratio of 1 to 2 between the front and rear axles, especially when a 17-ft. body, as supplied on the test chassis, is fitted. The rear overhang • was approximately 6 ft.

Mr. Larborn, the Volvo experimental engineer, was at the wheel when we left Gothenburg to drive to Slamby for the start of the hillclimb, Lakes Radasjon and Landvettersjon were frozen, but the road alongside had been cleared of snow to expose a cobbled surface. The Volvo, a left-hand-drive home model, had been reared on this type of road Surface, therefore the suspension was neither too harsh nor over-resilient.

Before reaching the village of

Slamby, we turned away from the lakes on to a minor road, which was coated with the frozen remains of snow, and started climbing from this

point This was a difficult ascent, because of ground conditions and the winding road. A stop was made at the foot of the hill to record the radiator top-tank temperature (144 degrees F.) and ambient (37 degrees F.).

There was initial wheelspin, but, with nursing, the Volvo negotiated the slope in second and third ratios in 4 mins. 5 secs Second gear was required at points where the gradient registered 1 in 12. The rise in water temperature was a mere 5 degrees F., but such a short climb would barely be sufficient to cause the thermostat to open.

Difficult Descent Sharp reverse-cambered bends made the descent to Partille more difficult than the climb, and I was glad to be the passenger and to find that the brakes were well suited to such work. Returning to Gothenburg, we afterwards headed south, towards Malmo, where there are many miles of good-surfaced road as level as a billiard table.

Here the Volvo showed its paces, and using second, third and fourth gears, it was accelerated from rest to 30 m.p.h. in 27.8 secs. Such acceleration is not common in oilengined chassis of this class. Bringing the overdrive ratio into action at 32 m.p.h.. the speedometer needle passed the 40 m.p.h. mark within 55.4 secs of starting.

Direct-drive acceleration was again in keeping with the power output, and throughout the governed range of the engine on full throttle, there was no visible sign of exhaust smoke. This points to good turbulence. the combustion space—a toroidal cavity—being formed in the crown of the aluminium-alloy pistons. The valves are tinshrouded.

A 60-ft. Stop from 30 m.p.h. I had yet to observe the full efficiency of the braking system and rigged the pistol on the running board to ascertain accurate results. An emergency application from 30 m.p.h. brought the Volvo to an abrupt stop within 60 ft., the Tapley meter showing maximum retardation of 97 per cent.

This effort caused wheel-locking on a dry and clean concrete surface, thereby showing that there was ample line pressure, coupled with a

large brake frictional area. This highstandard of retardation was maintained at 20 m.p.h., the stopping distance being 25 ft. 6 ins. Comparing the mark left by the pistol, on

A30

itial application, and the tyre arkings, there was a negligible lay in the pressure build-up of the ydrovac unit.

The solenoid switch was removed )m the pedal and replaced by the mrating plunger of the Mintex

.essometer Using a pedal effort 140 lb., I was able to reproduce e same Tapley readings as were Itamed during the previous tests. normal application of 45 lb. oduced a Tapley figure Of 88 per nt.

Using this reading as the optimum, aarnmenced warming the drums for e fade test by driving against the akes, using third gear and the celerator pedal hard on the flooriards. This was a test far more vere than the Volvo engineers had er tried, and they were keen to 'serve the results.

Drastic Treatment Maintaining 45 lb. pressure on the akcs, the facing material showed ins of heating at the end of a mile, iere the Tapley meter recorded 83 r cent. A further 10-per-cent. loss is experienced at the end of the cond mile.

Soon, increased pedal pressure was quired• to keen the speed to 18i m.p.h., as the expansion of the urns and the softening of the ction material had become more arked. At the third mile point e efficiency reading in stopping was Awed to 39 per cent., and this tire remained constant to the end of the trial. Resistance to fade was excellent and recuperation to normal was greatly assisted by the design of the drums to promote cooling.

Immediately afterwards came the fuel-consumption trials, the first being conducted on an out-andreturn level route, and the second in a hilly area which would compare with territory I normally choose for a road test in Britain.

The fuel test tank used for this trial was a slim, cylindrical unit, shaped in the fashion of a foam fire extinguisher •and equipped with a calibrated sight glass and spirit levels, so that it could be adjusted to the true vertical position.

Few cars or lorries were seen

throughout the day, and the absence of traffic lights or other delays presented ideal conditions for consumption trials. Except when starting from rest at each end of the level course, the overdrive ratio was employed all the time, so that the engine was running at an economical speed. The consumption rate over the out-and-return journey worked out to 17.5 m.p.g. at an average speed of 33.1 m.p.h.

Over the more undulating route there were a few occasions demanding brief use of direct drive, but because of the good power-to-weight ratio, overdrive was employed for 96.5 per cent. of the running time. Thi3 caused a slight increase in the fuel-consumption rate to 16.55 m.p.g., at an average speed of 33.1 m.p.h.

Economical for its Size

Considering the ample size of the Volvo power unit, its economy is good, and compared with its smaller contemporaries, it is only slightly below the average in consumption rate, measured in terms of m.p.g., for the 5-6-ton class of direct-injection oil-engined chassis.

Taking into account the average speed and load, and developing the consumption rate to the time-loadmileage factor, the high speed of the Volvo chassis brings the product well above average. For a 5-6-ton oilengined lorry, the average time-loadmileage factor is 4,100, whereas that of the Volvo, measured over the normal route, is 5,577.