DAIMLER INTRODUCES 8.6-LITRE OIL ENGINE

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

First Details of a 100 b.h.p. Ur Specifically for Bus Service. Co; Notable Feature ; Auxiliaries in F Main Unit and All Drive Gear + wheel End

AS we have already announced in " The Commercial Motor," the Daimler concern of Coventry has designed and developed a new compression-ignition bus engine. Now that this unit has -passed its various tests and is in production, it is possible to supplement our earlicr description with a full account of the engine and its performance on the bench.'

Besides economy of fuel, the purposes of this new design are to attain sufficient compactness for interchangeability with other engines used in the company's chassis, and to provide that high degree of reliability which is so necessary if maintenance charges are to be small. This latter con-. sider-ation depends largely on the rigidity of the main engine structure; primarily for that reason, the cylinder block and crankcase are cast together. Additionally, there is much well placed internal ribbing and the width of the base is generous.

With a bore of .4.5 ins and stroke of 5.5 ins., the six cylinders have a total displacement of 8.6 litres, They are arranged vertically in line and work on the four-stroke cycle, with vertical overhead valves operated by overhead rockers, short push rOds and hollow cast-iron tappets bearing on a camshaft placed high in the cylinder casting. The compression ratio is 15 to 1 and there is direct injection by either C.A.V. or Simms equipment, to the customer's choice. In both cases, the injectors are of the lour-spray type and engine speed is governed between 350 r.p.m. and 1,800 r.p.m.

Production Setting for 100 b.h.p.

Although this. engine will develop well over 120 b.h.p. without a smoky exhaust, the procluctiOn setting of the fuel injection pump is Chosen to. give a Maximum output of 100 .b.h.p., At this 'setting ' the fuel .consumption is virtually constant at about .34 pint per b.h.p. per hour over'a wide speed range, as may be ken from the curves-on

the accompanying graph. . .

Incidentally, an .interesting pdint isthe small difference in specific fuel• consumption between the settings for 105 ' b,h.p., maximum and 85 b.h.p. maximum; although there is an appreciable increge with 'the ' setting for 125 b.h.p.maximum,. the exhaust being then orr the threshold of smoke.

Reverting to the mechanical design, compactness has

• been attained largely.: by. arranging the auxiliaries in parallel with the main unit.. All. the drive gearis at; the rear or flywheel end of the engine in a-compartment formed in the main casting and provided with a large cover plate. Integral' with the crankshaft (and nitrided -with it) is a helical gear meshing with, a Tufnol idler which, in turn,

a24 drives a steel gear to operate the 7-in. 24-volt Simms dynamo and the water pump in tandem on the near side.

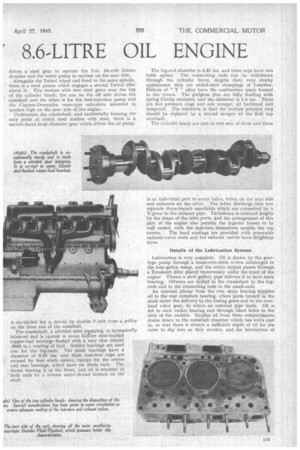

Alongside the Tufnol wheel and fixed to the same spindle, there is a steel pinion which engages a second Tufnol idler above it. This meshes with two steel gears near the top of the cylinder block; the one on the off side drives the camshaft and the other is for the fuel-injection pump and the Clayton-Dewandre vane-type exhauster mounted in tandem high on the near side of the engine.

• Underneath the crankshaft, and incidentally forming the only point at which steel meshes with steel, there is a narroiv-faced large-diameter gear which drives the oil pump.

A six-bladed fan is driven by double V. It from a, pulley on the front end of the camshaft.

The crankshaft, a nitrided steel stamping, is dynamically balanced and is carried in. seven .Glacier steel backed copper-lead bearings flashed with a very thin (about .0002 in.) coating of lead. Similar bearings are used also for the big-ends. The main bearings have a diameter of 3.35 inst and their cast-iron caps are secured by four studs apiece, except for the centre and rear bearings, which have six studs each, The thrust bearing is at the front, and oil is retained at both ends by a reverse screw-thread formed on the shaft. The big-end diameter is 2.81 ins, andthese caps have two bolts apiece. • The connecting rods can be withdrawn through the cylinder bores, despite their very stocky appearance; they are nickel-steel stampings of I-section. Pistons of." Y" alloy have the combustion space formed in the crown. The .gudgeonpins are fully 'loafing with spring Circlip retainers, and the-diameter is 1..5 ins. There are. five .pressure rings and Onescraper, all hardened and tempered. The intention is that the bottom 'pressure ring should be replaced by a 'second scraper 'at the first top overhaul.

The cylinder heads are cast in two sets of three and there is an individual port to every valve, inlets on the near side and exhausts on the other. The latter discharge into two separate three-branch manifolds which are connected by a Y-piece to the exhaust pipe. Turbitlence is attained largely by the shape of the inlet ports, and the arrangement of this part of the engine also permits the injector bosses to be well cooled, with the injectors, themselves outside the top covers. The head castings are provided with renewable exhaust-valve seats and the exhaust valves have Brightray faces.

Details of the Lubrication System Lubrication is very complete. Oil is drawn by the geartype punip through a brass-wire-mesh screen submerged in the fonr-gallon sump, and the entire output passes through a Tecalemit filter placed transversely under the.front.of the engine Thence a steel gallery pipe delivers it to each main bearing. Oilways are drilled in the crankshaft to the bigends and in the connecting rods to the small-ends.

An internal oilway from the rear main bearing supplies oil to the rear camshaft bearing, where ports formed in the shaft meter the delivery to the timing gears and to the overhead valve gear, to which an external pipe leads. Oil is fed to each rocker bearing and through bleed holes to the ends of the rockers. Surplus oil from these compartments drains down to the camshaft chamber which has weirs cast in, so that there is always a sufficient depth of oil for the cams to dip into as they revolve, and, for lubrication of the seven camshaft bearings. The normal oil pressure is SO lb. per sq. in.

Cooling water is delivered• from the pump to a gallery cast in the cylinder block near its' top -face. Thence it travels up to the head castings through six holes, one near each injector boss. Other larger holes on both sides connect the head jackets to the cylinder jacket in which local therrno-syphonic circulation takes place. This arrangement helps a rapid attainment of the normal working temperature around the cylinders and ensures adequate cooling of the injectors and exhaust valves as well as the hot part of the cylinder wall near the offset combustion chamber.

There is a thermostat in the outlet pipe and a bypass from it to the water pump takes the circulation while the

thermostat is closed. The cooling eater capacity is 10 gallons.

'The water pump is of the vane type and its. wheel is mounted on two spaced ball bearings. Lubrication is by grease nipple and the gland is a spring-loaded carbon ring bearing against a polished ;cast-iron• face. The ptunp is easily detachable and, as .already. indicated, it is situated near the front of the engine on the near side.

'To this engine is fitted the latest open-circuit type of Daimler Fluid Flywheel'which ^ has no cairity ring. It has better slip.echaracteristics than had the earlier designs, and was developed, originally, to .withstand the heavy duties imposed by certain tmilitary applications. Its merits are shown, particularly, during .iiigh-torque low-speed work, so it should be especially valuable in ,city-bus service. Oil

leakage has been virtually eliminated. ,

Mounted detachably on the steel fly,a,heel is a steel starter-gear,ring. The starter is. a 24-,volt Simms of axial type, placed near the rear of the engine on the off side.

Power, torque and fuel consumption characteristics can best be seen in the relevant curves, but two items not shown there deserve special -mention. Both relate to smoothness of operation.. We have seen one of these engines running. on. the bench and were impressed by the steadiness and quietness of its tick-over.

Combustion-chamber design may be partlyl responsible for this, but Mr. C. M. Simpson, the company's chief engineer, attributes it largely to the fact that the fuelinjection pump is driven from the flywheel-end of the crankshaft. At this end, cyclic speed variation is naturally at a minimum and there is consequently no " fighting " or hacklashing in the drive. This permits the low-speed governor to function smoothly, there being no disturbances to fintter. its necessarily light springs. In short, the injection proceSs is just as accurate at low speeds as it is at other points in the range.

The second item relates to torsional vibration of the crankshaft. In the original design, provision was made for the incorporation of a crankshaft damper, although the dimensions of the shaft were calculated to put its critical' speed well above the governed maximum. The sequel testifies that theory and practice can happily agree.

'Careful tests and measurements showed that practically no torsional oscillation occurs at any point in the speed range. The greatest twist observed, in fact, was so §mall that no known practicable form of damper could have reduced it to any appreciable extent. In other words, a damper is quite unnecessary and therefore none is fitted. . It may be true that this new Daimler engine incorporates no major feature which has not been seen before. It certainly is true that all its features are skilfully blended. This, in brief, is a tine example of sound design based on well-proven engineering principles, and there can be no doubt that the Daimler oil engine will soon earn an eXcellent reputation.