Fleet Operation

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

Shorn of Frills TLS article should really be entitled FI" How to Maintain a Fleet of 41 Vehicles with a Garage Manager, Three

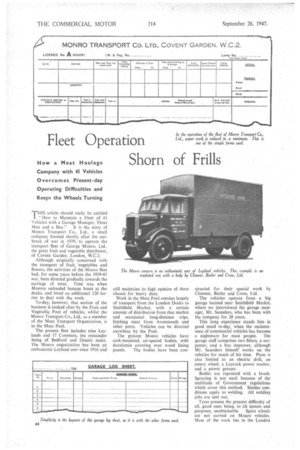

Men and a Boy." It is the story of Monro Transport Co., Ltd., a small company formed shortly after the outbreak of war in 1939, to operate the transport fleet of George Monro. Ltd., the great fruit and vegetable distributor, of Covent Garden, London, W.C.2.

Although originally concerned with the transport of fruit, 'vegetables and flowers, the activities of the Monro fleet had, for some years before the 1939-45 war, been directed gradually towards the carriage of meat. Time was when Monros unloaded banana boats at the docks, and hired an additional 120 lorries to deal with the work.

To-day, however, that section of the business is looked after by the Fruit and Vegetable Pool of vehicles, whilst the Monro Transport Co., Ltd., as a member of the Meat Transport Organization, is in the Meat Pool.

The present fleet includes nine Leylands and 17 Commers, the remainder being of Bedford and Dennis make. The Monro organization has been an enthusiastic Leyland user since 1916 and still maintains its high opinion of these chassis for heavy duty.

Work in the Meat Pool consists largely of transport from the London Docks to Smithfield Market, with a certain amount of distribution from that market and occasional long-distance trips, fetching meat from Avonmouth and other ports. Vehicles can be directed anywhere by the Pool.

The present Monro vehicles have cork-insulated, air-spaced bodies, with duralumin covering over wood lining panels. The bodies have been con structed for their special work by Clement, Butler and Cross, Ltd.

The vehicles operate from a big garage located near Smithfield Market, where we interviewed the garage manager, Mr. Saunders, who has been with the company for 28 years.

This long experience stands him in good stead to-day, when the maintenance of commercial vehicles has become a nightmare for most people. The garage staff comprises two fitters, a carpenter, and a boy improver, although Mr. Saunders himself works on the vehicles for much of his time. Plant is also limited to an electric drill, art emery wheel, a Laycock power washer, and a power greaser.

BodieG are repainted with a brush. Spraying is not used, because of the multitude of Government regulations which cover this method. Similar conditions apply to welding. All welding jobs are sent out.

Tyres present the greatest difficulty of all, good ones being. to all intents and purposes, unobtainable. Spare wheels are not carried on Monro vehicles. Most of the work lies in the London area, but even on long journeys the lorries are sent out without spares, as so many have been stolen in recent years.

It might seem risky to send a vehicle from London to Avonmouth without a spare wheel, but there are certain points in, favour of the practice, as Mr. Saunders explained, apart from the elimination of theft., No driver's mate is carried, and even if a spare wheel_ were provided, the driver alone could hardly change a rear wheel. Moreover, should trouble occur on the road, some good-natured country garage owner will usually supply him with a tyre to get him home.

Safety Bonus

A bonus of one full week's wages is given to every driver who gets through 12 months without an accident, and most of the men earn it. "Accidents" moreover, include blows to stationary vehicles.

Attention to brakes and steering is naramount in the .tnaintenance of Ate, tieet. When drivers are interrogated as to the condition of their vehicles, two questions are alWays asked_ before.. others., "Can you steer it? Can you

stop it?

Maintenance in general is conducted on a time, rather than on a mileage, basis, but there is no set time at which a vehicle is withdrawn from service.When it starts to give trouble, it comes

in foran overhaul. _ • Drivers' report sheets are the exact opposite of an official form. They would, in fact, cause the average senior civil servant to smirk, as they are designed to give essential information, and nothing else. Two of the forms used in the control of the fleet are reproduced.

It might be imagined that, because of the shortage of plant, major overhauls would be sent out. That is not the case. Chassis are stripped down in the garage and worn or damaged parts replaced by new ones.

Specialist Repairs Welding jobs, as already mentioned, are sent oat, as also are spring repairs —always a specialist's job—and cylinder blocks requiring to be rebored. For the rest, practically everything is -done on the spot by the fitters and the garage manager himself.

The simplicity of this arrangement may not appeal to operators, but it certainly appears to work efficiently in the case of Monro Transport Co., Ltd. Vehicles are kept in service for long periods and give remarkably little trouble.

As an example, one Leyland belonging to the company has covered more than 190,000 miles since 1931. It is now employed on London dock work and is good for many more years of useful

,ervic.e. We were told that Leyland Nlotors,., Ltd., is particularly helpful in I he matter of supplying spares—even in 'hese difficult days.