"WE PROUD OF OUR PER DRIVERS"

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

A sense of I an equable a 1g gives Pointer Group drivers to tricky site problems a long y from home

IF attack is the best form of defence, it is axiomatic that expansion is the best way of competing for traffic in a keen market. But in the case of a tipper fleet, the ;uccess of expansion is conditional on the traffic potential of the immediate area, or on the ability of the operator to concentrate sections of his fleet, at least temporarily, at appropriate focal points over a much wider area.

When long-distance transport was denationalized in 1953, the Pointer Group, Guardian Road, Norwich, were fortunate in the possession of a fleet of some 100 vehicles that had escaped the acquisitive attention of the State, and the subsequent take-over of a number of haulage concerns in East Anglia (there are now 16 companies in the group) enabled the company rapidly to expand its long-distance operations to meet a growing demand. Over 200 heavy lorries out of a fleet total of about 300 vehicles are now engaged in the carriage of general. goods, bulk liquids and prefabricated units of steel or concrete, and further expansion is likely.

In the case of tipper traffic, local expansion was strictly limited by the predominantly agricultural activities of the community, and it was necessary to create a flexible organization that would cater for the requirements of contractors operating in areas remote from the main depot. At the same time it was fully appreciated that drivers represent the most important element in the success of any project and that maintaining a team spirit and a "sense of belonging" amongst a group of men a long way from home is essential to co-ordinated effort and to good staff relations all round.

About 85 tippers are ,continuously engaged in roadbuilding work, and a substantial proportion may be temporarily based at distant sites up to 300 miles from Norwich. The teams of men who 'accompany the vehicles

B32 are provided with accoinmodation in caravans Owned by the company, or in local lodgings, and a mobile workshop is sent to the site, whiCh is in the charge of a fully-qualified mechanic. Although the site staff must be temperamentally suited to "moving from place to place" they work on a rota system, so that they are seldom away from home for more than a week or two. Vehicles may operate up to 40 miles from their temporary base.

"We are proud of our drivers," emphasizes Mr. P. H. Pointer, director of the group, "and we are proud of their record in the districts in which they have worked." In some cases, the prospect of intensive tipper operations in a locality has created apprehemion on the part of the residents which has taken an overt form, but inevitably this has been followed in due course with official appreciation of the drivers' general conduct and for their regard for the interests (and prejudices) of the inhabitants. An equable temperament is considered the most important factor in the make-up of a tipper driver's character, and it is notable that a number of drivers have worked for the group for over 20 years. They receive every assistance from senior members of the exectitive staff, a careful survey of an area being made before the start of an operation. Every driver is required to have a detailed knowledge of traffic regulations.

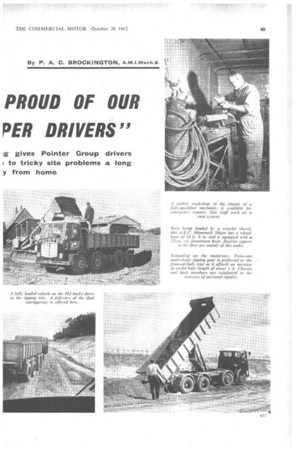

When expansion of the tipper fleet was being planned, it was considered that a high-capacity, dual-purpose maximum-load eight-wheeler could he employed that would be suitable for the carriage of both tight and heavy materials. After a fairly long testing period, it was decided, however, that the use of a vehicle with a robust chassis, con-alined with heavy-duty tipping.gear and lifting frame. Was

of greater practical importance than obtaining the maximum payload, despite the fact that the vehicles would be heavier than they need be for the transport of bulky materials. Accurate matching of vehicle chassis, lifting gear and body structure is considered essential.

Aluminium bodies with a capacity of 12 cu. yd. are fitted to the majority of the heavier vehicles, which represents a sacrifice in payload of more than a cubic yard (or about 1-1 tons) compared with the load that could be carried if a lighter chassis and gear were employed.

In the main, the heavy tippers are mounted on A.E.C. Mammoth Major chassis of 14-ft. 8-in, wheelbase, powered by the maker's 9.6-litre engine, and lifting gear comprises Edbro or Pilot twin-ram underbody gear. This type is preferred to front-of-body gear because it affords an increase in the useful body length of about 1 ft. without attendant disadvantages with regard to strength characteristics, given that the vehicle chassis and lifting frame are adequately reinforced. Both the chassis members and body frame are normally boxed-in to increase the overall strength of the entire structure and to give uniform distribution of torsional stresses.

On a typical site, tipping is frequently performed on very uneven or louse ground, and torsional rigidity of the structure promotes uniformity of ram action, which is particularly valuable if a "sticky " material is being handled. In very adverse conditions, however, maintaining a reasonable margin of safety is dependent upon the experience and intelligence of the driver.

The relatively high first cost and repair costs of aluminium bodies are offset by the gain in payload they afford, the importance of which is increased by the reduced capacities of the bodies and by a strict embargo on over a34 loading. Comparatively rapid wear of the aluminium by gravel abrasion is the main operational disadvantage of employing light-alloy bodies. The U-shaped body is nearideal for some types of material, but is not a good generalpurpose type. All aluminium bodies tend to distort and refitting to another chassis of the same model normally presents a number of difficult problems.

Servicing Particular tribute is paid to the nation-wide servicing facilities provided by the A.E.C. company, which enable the maintenance schedules of the site, teams to be simplified by virtue of the ready availability of spares anywhere in the country. Power units are given a top overhaul after 70,000 miles and pistons are renewed at this mileage in the unusual event of ring-groove wear being excessive. Reboring is performed "as required," the upper mileage limit being normally about 150,000.

Rotella T 10W30 lubricating oil is used for all the diesels, and the oil is changed after 5,000 miles. The use of one grade of oil simplifies storage and eliminates incorrect selection, whilst the multi-grade properties of the lubricant promote easier starting and a long battery life. Radiators are partly blanked-off in winter to give more efficient engine operation and to reduce cold corrosion, and an anti-freeze solution is added to the coolant. It has been noted that anti-freeze has a penetrating action that sometimes increases the likelihood of cylinder gasket failure.

Acting on the principle that "smoke costs money," pumps and injectors are regularly checked and serviced by two full-time fully qualified fitters with the aid of Merlin equipment, and faulty units are immediately replaced. The fitters of the injection shop are also responsible for road testing the vehicle fortnightly to ensure that the engine is free from undue smoking over the entire load-speed range.

After extended experiments with various types of air filter, the oil bath type has been retained in service but the unit is now mounted inside the cab at a high level. This reduces the amount of dust drawn into the filter and the air is relatively cool, which improves engine performance.

Dunlop tyres are used throughout the fleet, and this concentration on one make has reduced the stock of spare tyres required by two-thirds and ensures uniformity of diameter and tread pattern, tyre life varying between 25,000 and 70,000 miles. One or two other makes are employed in small numbers to afford a comparison of wear life. New tyres are fitted to the tankers and after retreading they are transferred to long-distance platform vehicles. After they have been retreaded a second time they are fitted to tipping vehicles.