For DRIVERS, MECHANICS & 'FOREMEN.

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter whi5h we publish on this page, and an EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D.,. M. ,and F., "The Commercial Motor," 7-15, Rosebery Avenue, London, B.C. 1.

Lamps Alight.

On Satuiday, October 30th, light your larnp,s at 5.6 in, Loudon, 5.7 in Edinburgh, 5.2 in Newcastle, 5.13 in Lrvvreool, 5.1? in Birmingham, 5.16 in Bristol, and 6.6 in Dublin.

Useful Homemade Hand-drill Attachment.

The sender of the following communication has been awarded the eitra payment of Sc this week.

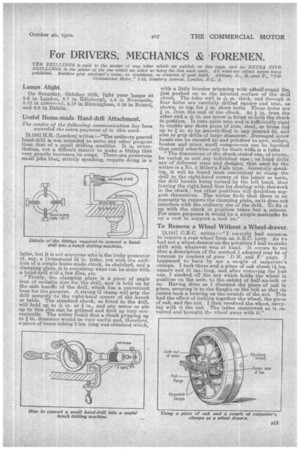

[2,150] H.B. (London) writes:—"The ordinary geared hand-drill is not intended to serve any other purpose than that of a small drilling machine. • It is, nevertheless, not a difficult matter to make a fitting that very greatly increases its scope. There are numerous small jobs that,. strictly speaking, require doing in a lathe, but it is not everyone who is the lucky possessor of, say, a Drummond 31 in. lathe, yet with the addition of a simple home-made chuck, as sketched, and a clamping plate, it is surprising what can be done with a hand-drill a-,d a few files, etc.

" Firstly? the clamping plate is a piece of angle iron of suitable size for the drill, and is held on by the side ha,nclie of the drill, which has a convenient boss for the purpose. A strong G clamp will grip the drill securely to the right-hand corner of the bench or table. The standard chuck, as fitted to the drill,

will hold up to in or in., and any screw or pin up to this size can be gripped and filed up very conveniently. The writer found that a, chuck gripping up to in. diameter would be very useful and, therefore, a piece of brass tubing 3 ins, long was obtained which, with a little interior trimming with athalf-round file, just pushed on to the _knurled surface of the drill' chuck. The tube wall is -A.m. thick, and through it four holes are carefully drilled square. and true, as shown to tap for in. short bolts. These holes are in, shown, the end of the chuck. At 1 in. from the

other end a tlein. set screw is fitted to hold the chuck in position. It runs quite true and is tiufficiently rigid to enable any short piece of iron, steel, or brass rod up to I in. to be smooth-filed to any desired fit, and also to grip drills of large .diaaneter... Damaged screw heads can be cleaned up and polished as new, collars, bushes and many small components can be handled that could otherwise only. be dealt with% in a lathe "The dimensions of the chuck stated can, of course, be varied to suit any individual case,as hand drills are of-different sizes and ,designs, that used by the writer is a No. 2 Miller's Falls type. Generally speaking, it will be found most convenient to clamp the drill to the right-hand corner of the bench or table, the drill handle being turned by the left hand, thus leaving the right-hand free for dealing witInthei work in the chuck ; but other positions will, doubtless suggest themselves. The writer finds that there is no riecessityto remove the clamping plate, aoit does not interfere with the ordinary. use of the drill. To fix it up with the chuck in position takes but a, minute. For some purposes it would be a simple mattereto fit up a rest to support a tool on."

To Remove a Wheel Without a Wheel-drawer.

[2,151] C.R.C. writes :—" I. recently had occasion to remove a rear wheel from an A.E.C. lorry. As we had not a wheel-drawer on the premises I had to make shift with whatever was at hand. It occurs to me that a. description of the method I adopted may be of interest to readers of your D.M. and F.' page. I happened to have by me a couple of carpenter's clamps. I took-these and a piece of oak about 11 ins. square and 18 ins.., long, and after removing the hub cap, I slacked off the nut which holds the wheel in position on the axle, to the extent of half-an-inch or so. Having done so I clamped the piece of oak in place, securing it to the flanges on the hub so that its centre took a bearing on the outside of the nut. This had the effect of locking together the wheel, the piece of oak, and the nut. I then revolved the wheel, carrying with it the nut. The latter unscrewed as it revolved and brought the wheel away with it."