AN IMPROVED TYPE OF CYLINDER LINER.

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

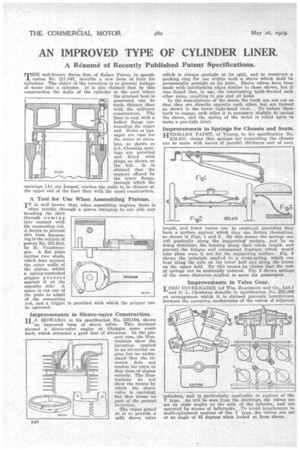

TIIE well-known Swiss firm of Sulzer Freres, in specification No. 211,847, describe a new form of liner for cylinders. The object of the invention is to prevent leakage of water into a cylinder. It is also claimed that by this construction the walls of the cylinder at the part where the greatest heat is generated can be made thinner than with the ordinary, construction. The liner is cast with a hollow flange surrounding the upper end. Holes or passages are cast for the water to circulate, as shown at .AA. Cleaning openings are provided and fitted with plugs, as shown on the left. It is claimed that the support offered by the lower flange, through which the openings (A) are formed, enables the walls to be thinner at the upper end of the liner than with the usual construction.

A Tool for Use When Assembling Pistons.

IT is well known that, when assembling engines, there is Improvements in Sleeve-valve Construction. II J. HOWARD, in his specification No. 230,194, shows an improved form of sleeve valve. This inventor showed a sleeve-valve engine at Olympia • some years back, which attracted a good deal of attention. In the present case, the illustrations show the invention applied to an air-cooled engine, but we understand that the inventor does net confine his valve to that class of engine entirely. The illustrations do not show the means by which the sleeve valve is operated, but that forms no part of the present invention.

The object aimed' at is to provide a split sleeve valve which is always gastight at its split, and to construct a packing ring for use within such a sleeve which shall be permanently gastight at its joint. Sleeve valves have been made with interlocking edges similar to those shown, but it was found that, in use, the interlocking teeth 'fretted each other away, resulting in gas and oil leaks.

In the manufacture of the sleeve the teeth are not cut so that they are directly opposite each other, but are formed as shown in the lower right-hand view. To induce these teeth to engage each other it is necessary slightly to spring the sleeve, and the spring of the metal is relied upon to make a gas-tight joint.

Improvements in Springs for Chassis and Seats.

HERMANN PAPST, of Vienna, in his specification No. 232,410, claims that springs for supporting the chassis can be made with leaves of parallel thickness and of even length, and fewer leaves can be employed providing they have a surface against which they can flatten themselves, as shown in Figs. 1 and 2. By this means the springs can roll gradually along the impportine surface, and by so doing distribute the bending along their whole length, and prevent the fatigue and consequent fracture. which would take place were it not for the supporting surface. Fig. 2 shows the principle applied to a cross-spring, which can bear along the axle on the lower half and along the frame on the upper half. By this means he claims that the cost of springs can he materially reduced. Fig. 3 shows springs of the same character applied to seats for passengers.

Improvements in Valve Gear.

LORD INVERNAIRN (of Wm. Beardmore and Co., Ltd.)' and E. L. Chorleton describe in specification No. 232,399 an arrangement which it is claimed prevents interference between the cperating mechanisms of the valves of adjacent cylinders, and is particularly applicable to engines of the V type. As will be seen from the drawings, the valves are set at right angles to the axis of the cylinder, and are operated by means of bellcranks. To avoid interference in multi-cy.lindered engines of the V type, the valves are set at an angle of 45 degrees when looked at from above.