HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

618.—Some Facts Concerning the Hanford Radiator.

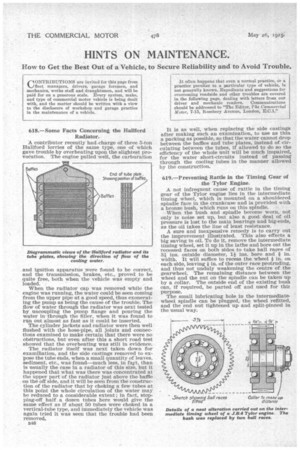

A contributor recently had .charge of three 5-ton Hallford lorries of the same type, one of which gave trouble by overheating upon the slightest provocation. The engine pulled well, the carburation

and ignition apparatus ;were found to be correct, and the transmission, brakes, etc., proved to be quite free, both when the vehicle was empty and loaded.

When the radiator cap was removed while the engine was running, the water could be seen corning from the upper pipe at a good speed, thus exonerating the pump as being the cause of the trouble. The flow of water through the radiator was next tested by uncoupling the pump flange and pouring the water in through the filler, when it was found to run out almost as fast as it could be inserted.

The cylinder jackets and radiator were then well flushed with the hose-pipe, all joints and connections examined to make certain that there were no obstructions, but even after this a short road test showed that the overheating was still in evidence.

The radiator itself was next taken down for exanathation, and the side castings removed to expose the tube ends, when a small quantity of leaves, sediment, etc., was found—much less, in fat, than Is usually the case in a radiator of this size, but it happened that what was there was concentrated at the upper part of the radiator just above the bailie on the off side, and it will be seen from the construction of the radiator that by choking a few tubes at this point the whole circulation of the water may be reduced to a considerable extent ; in fact, stopping-off half a dozen tubes here would give the same effect as if about 50 tubes were choked in a vertical-tube type, and immediately the vehicle was again tried it was seen that the trouble had been removed.

MS

It is as well, when replacing the side castings after making such an examination, to use as thin a packing as possible, so that the water cannot drop between the baffles and tube plates, instead of circulating between the tubes, if allowed to do so the efficiency of the whole unit will be much impaired, for the water short-circuits instead of passing through the cooling tubes in the manner allowed by the construction.

619.—Preventing Rattle in the Timing Gear of the Tylor Engine.

A not infrequent cause of rattle in the timing gear of the Tylor engine lies in the intermediate timing wheel, which is mounted on a shouldered spindle face in the crankcase and is provided with a bronze bush, which runs on this spindle.

When the bush and spindle become worn, not only is noise set up, but also a good deal of oil pressure is lost to the main bearings and big-ends, as the oil takes the line of least resistance.

A sure and inexpensive remedy is to carry out the improvement illustrated. This also effects a big saving in oil. To do it, remove the intermediate timing wheel, set it up in the lathe and bore out the recessed faces on both sides to take ball races of 3# ins, outside diameter, 1# ins, bore and # in. width. It will suffice to recess the wheel # in. on each side, leaving # in. of the outer race protruding, and thus not unduly weakening the centre of the gearwheel. The remaining distance between the wheel and the nut on the spindle can be taken up by a collar. The outside end of the existing bush can, if required, be parted off and used for this purpose.

The small lubricating hole in the intermediatewheel spindle can be plugged, the wheel refitted, and the end nut tightened up and split-pinned in the usual way.