New Heavy-duty Universal Joint

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

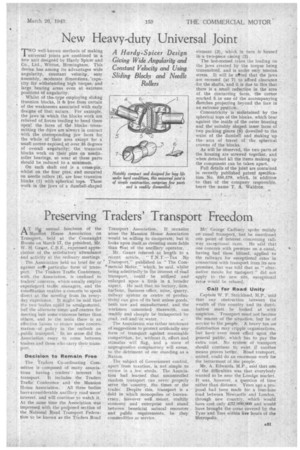

A Hardy-Spicer Design Giving Wide Angularity and Constant Velocity and Using Sliding Blocks and Needle Rollers

erNVO well-known methods of snaking 1 universal joints are combined in a new unit designed by Hardy Spicer and Co., Ltd.. Witton, Birmingham. This device has among its advantages wide angularity, constant velocity, easy assembly, moderate dimenSions, 'capa'city for withstanding high torque, and large bearing areas even at extreme positions of angularity.

Whilst of the.type employing sliding ttunnion blocks, it is free from certain of the weaknesses associated with early designs of that nature. For example, the jaws in which the blocks work are relieved of forces tending to bend them open; the faces of the blocks transmitting the drive are always in contact with the corresponding jaw faces for the whole of their area except for a small corner• exposed, at over 35 degrees of overall angularity; the trunnion blocks work on their pins on needleroller bearings, so wear at these parts should be reduced to a minimum.

On each shaft end is a cross-pin, whilst on the four pins, anct mounted on needle rollers (4), are four trunnion blocks (I) with spherical tops. These work in the jaws of a dumbell-shaped element (3), which in turn is housed. in-a two-piece casing (2). The last-named takes the loading on the jaws created by the torque being transmitted, and is under only tension_ stress. It will be nated that the jaws are recessed (at 7) to afford clearance -for the shafts, and it is due to this that there is a small reduction in the area of the contacting faces, the corner marked 5 in one of the accompanying sketches projecting beyond the face in an extreme position. Concentricity is maintained by the spherical tops of the blocks, which bear against the inside of the outer housing and the suitably shaped inner faces of two packing pieces (6) dowelled to the waist of the dumbell and Making up thearcs of travel of the spherical crowns of the blocks.

As will be observed, the two parts of the housing are screwed together, and when detached all the items making up the component can be taken apart. Full details of the joint are contained in recently published patent specification No. 550,579, which, in addition to that of the company responsible, bears the name T. A. Waldron.