A Battery Safety Switch

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

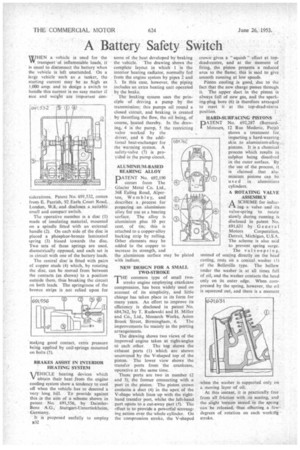

WHEN a vehicle is used for the W transport ofinflammable loads, it is usual to disconnect the battery when the vehicle is left unattended. On a large vehicle such as a tanker, the starting current may be as -high as 1,000 amp. and to design a switch to handle this current is no easy matter if size and weight are important con siderations. Patent No. 691,532, comes from E. Parrish, 92 Earls Court Road, London, W.8, and discloses a suitable small and compact switch.

The operative member is a disc (1) made of insulating material, mounted on a spindle fitted with an external handle (2). On each side of the disc is placed a phosphor-bronze laminated spring (3) biased towards the disc. Two sets of these springs are used, diametrically opposed, and each set is in circuit with one of the battery leads.

The central disc is fitted with pairs of copper studs (4) which, by rotating the disc, can be moved from between the contacts (as shown) to a position outside them, thus breaking the circuit on both leads. The springiness of the bronze strips is not relied upon for

making good contact, extra pressure being applied by coil-springs mounted on bolts (5).

BRAKES ASSIST IN INTERIOR HEATING SYSTEM VEHICLE heating devices which V obtain their heat from the engine cooling system show a tendency to cool off when the vehicle has to descend a very long hill. To provide against this is the aim of a scheme shown in patent. No. 691,556, by DaimlerBenz A.G., Stuttgart-Untertiirkbeirri, Germany.

lt is proposed usefully to employ B32 some of the heat developed by braking the vehicle. The drawing shows the complete layout in which 1 is the interior heating radiator, normally fed from the engine system by pipes 2 and 3. In this case, however, the piping includes an extra heating unit operated by the brake.

The braking system uses the principle of driving a pump by the transmission; this pumps oil round a closed circuit, and braking. is created by throttling the flow, the oil being, of course, heated thereby. In the. drawing, 4 is the pump, 5 the restricting valve worked by the driver, and 6 the additional heat-exchanger for the warming systern. A safety-valve (7) is provided in the pump circuit.

ALUMINIUM-BASED BEARING ALLOY DATENT No. 692,190 comes from The Glacier Metal Co. Ltd., 368 Ealing Road, Alperton, Wembley, and describes a process for preparing an aluminium alloy for use as a bearing surface. The alloy is aluminium plus 10 per cent, of tin; this is attached to a copper-alloy backing strip by rolling. Other elements may be added to the copper to increase its strength, and the aluminium surface may be plated with indium, NEW DESIGN FOR A SMALL TWO-STROKE THE common type of small two'. stroke engine employing crankcase compression, has been widely used on account of its simplicity, and little change has taken place in its form for many years. An effort to improve its efficiency is disclosed in patent No. 684,762, by T. Rudawski and H. Miller and Co., Ltd., Monarch Works, Aston Brook Street, Birmingham, 6. The improvements lic mainly in the porting arrangements.

The drawing shows two views of the improved engine taken at right-angles to each other. The top shows the exhaust ports (1) which are shown uncovered by the V-shaped top of the piston. The lower view shows the transfer ports from the crankcase, operative at the same time.

These ports are two in number (2 and 3), the former connecting with a port in the piston. The piston crown contains a duct (4) in the apex of the V-shape which lines up with the righthand transfer port, whilst the left-hand port opens to a cut-away part (5). The effect is to provide a powerful scavenging action over the whole cylinder. On the compression stroke, the V-shaped crown gives a "squish" effect at topdead-centre, and at the moment of firing, the piston presents a reduced area to the flame; this is said to give smooth running at low speeds.

Piston cooling is good, due to the fact that the new charge passes through it. The upper duct in the piston is always full of new gas, and the sparking-plug bore (6) is therefore arranged to meet it at the top-dead-centre position.

HARD-SURFACING PISTONS

PNo. 692,287 (BernardMoteurs, 12 Rue Mederic, Paris) shows a treatment far, imparting a hard-wearing. skin to aluminium-alloy pistons. It is a chemical process which results iii. sulphur being dissolved in the outer surface. By the use of the process, it is claimed that aluminium pistons can used in aluminium cylinders.

A -ROTATING VALVE ASSEMBLY ASCHEME for inducing a valve and its valve-spring to rotate slowly during running is disclosed in patent No. 691,631 by General

Motors Corporation, Detroit, Michigan, U.S.A. The scheme is also said to prevent spring surge.

The valve-spring, instead of seating directly on the head casting, rests on a conical washer (I) of the Belleville type. The hollow under the washer is at all times full of oil, and the washer contacts the headonly on its outer edge. When compressed by the spring, however, the oil is squeezed out, and there is a moment

when the washer is supported only on a moving layer of oil.

At this instant, it is practically free from all friction with its seating, and the slight torsion stored in the spring can be released, thus effecting a few degrees of rotation on each working stroke.