AIDS TO SOLVING FORD PROBLEMS.

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are em ployed for commercial purposes, we propose

• to deal with the subject from, every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information are being tapped for this purpose, and it should be understood that the information given will be derived from those with an intimate knowledge of the subject. We shall welcome foe inclusion amongst the hints those which have proved of value to individual users, and will make suitable remuneration • for any published. What we desire are the results of practice.

55.—Hints Which Will Assist Dismantling.

A difficulty is sometimes experienced in removing the stub axle bushes. If a tap be screwed into the bush it will be found quite easy to drive out this from the opposite end ; the bush will then travel out with the tap. As the tap is hardened it should be treated with Care, and a piece of wood should be interposed between it and the hammer.

The stub axle pin will sometimes be found to be almost immovable owing to the portion in the top lug of the axle _having no means of lubrication. This difficulty can be overcome by cutting about 2 ins. off the universal end of an old driving shaft, which should then be drilled in. and tapped the same thread as the pin. By screwing this tool on to the bottom of the pin and using, a spanner on the square, as well as the key which is normally used for the top of the pin, the last-named can easily be moved. The head of the fan spindle is another part some-, what difficult to extract, as it cannot easily be gripped. To remove it, use can again be made of the special tool just described, but in this case the other end should be drilled in. and tapped to suit.

56.—Greasing the Front-wheel Bearings.

One of our contributors has found that the method of greasing the front-wheel bearings by filling the hub caps with grease and screwing them on has proved unsatisfactory, as very little of the lubricant gets to the inner bearings. He 'has, therefore, adopted a different method, which, he states, gives greater satisfaction.

• In the centre of each hub he drilled and tapped a 5-16-in. hole. This is normally kept closed by a setscrew. When the hub requires lubricating, use is made of a grease gun having a flexible tube Provided with a 5-1a-in. screwed nipple at the end. This is inserted into the hole drilled into the hub, and each bearing is then given its fair share of grease.

This idea can be used in connection with either detachable wheels or those with detachable rims.

Where a grease .sun is not available, a Stauffer lubricator can be employed, but in those cases where detachable wheels are fitted, it is necessary to unscrew

t h e Stauffer from the h u b every time a

wheel i s changed.

57.—Curing an Obscure Trouble in a Ford Coil.

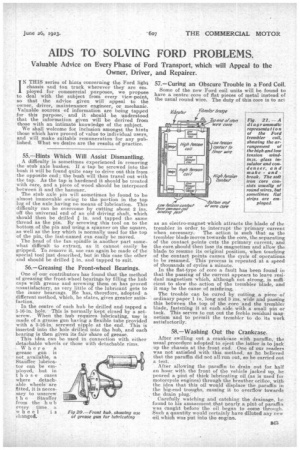

Some of the new Ford coil units will be found to have a centre core of flat pieces of metal instead of the usual round wire. The duty of this core is to act as an electro-magnet which attracts the blade of the trembler in order to interrupt the primary current when necessary. The action is such that as the trembler blade moves towards the core, the separating of the contact points cuts the primary current, and the core should then lose its magnetism and allow the blade to resume its original position, when touching of the contact points causes the cycle of operations to be resumed. This process is repeated at a speed of thousands of cycles a minute.

In the flat-type of core a fault has been found in that the passing of the current appears to leave residual magnetism which, although not strong, is sufficient to sieve:, the action of the trembler blade, and it may be the cause of misfiring..

The The trouble can be cured by cutting a piece of ordinary paper 1 in. long and 3 ins, wide and Passing this between the top of the core and the trembler blade, fastening it at each side with a small pin or tack. This serves to cut out the feeble residual Magnetism and to permit the trembler to do its work satisfactorily.

• 58.—Washing Out the Crankcase.

After swilling out a crankcase with paraffin, the usual procedure adopted to eject the latter is to jack up the chassis at the front end. One of our readers was not satisfied with this method, as he believed that the paraffin did not all run out, 60 he carried out a test

After allowing the paraffin to drain out for half an hour with the front of the vehicle jacked up, he poured a pint of thick lubricating oil (as is used for motorcycle engines) through the breather orifice, with the idea that this oil would displace the paraffin in the big-end troughs, causing it to overflow towards the drain plug.'

Carefully watching and catching the drainage, he found to his amazement that nearly a pint of paraffin was caught before the oil began to come through. Such a quantity would 'certainly have diluted any new oil which was put into the engine.