SIMPLE

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

PilkilICHAIN ICS

Torque wrench settings

WHEN RE-ASSEMBLING any motor vehicle parts it is vital that the nuts, bolts or set screws used to fasten components together are tightened correctly. If too much force is used a thread may strip, a stud may break, or the component may be distorted.

On the other hand if the nut or bolt is not tightened enough, then leaks of oil, fuel, water or gas may result, the nut may slacken off, or damage may be caused to adjacent parts.

A skilled fitter will often be able to tighten a nut without a specialised tool, but this sort of skill only comes after many years of practice and, in any case, it is far better to use the proper tool available for this job. A torque wrench will ensure that exactly the correct force is applied for the particular job in hand.

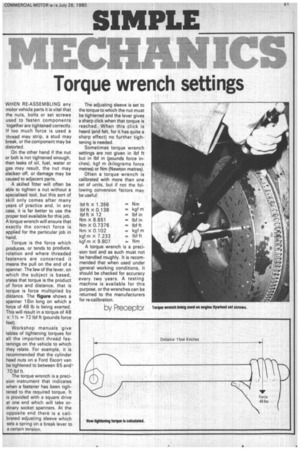

Torque is the force which produces, or tends to produce, rotation and where threaded fasteners are concerned it means the pull on the end of a spanner. The law of the lever, on which the subject is based, states that torque is the product of force and distance, that is torque is force multiplied by distance. The figure shows a spanner 18in long on which a force of 48 lb is being exerted. This will result in a torque of 48 x 11/2 = 72 lbf ft (pounds force feet).

Workshop manuals give tables of tightening torques for all the important thread fastenings on the vehicle to which they relate. For example, it is recommended that the cylinder head nuts on a Ford Escort van be tightened to between 65 and 70 lbf ft.

The torque wrench is a precision instrument that indicates when a fastener has been tightened to the required torque. It is provided with a square drive at one end which will take ordinary socket spanners. At the opposite end there is a calibrated adjusting sleeve which sets a spring on a break lever to a certain tension. The adjusting sleeve is set to the torque to which the nut must be tightened and the lever gives a sharp click when that torque is reached. When this click is heard (and felt, for it has quite a sharp effect) no further tightening is needed.

Sometimes torque wrench settings are not given in lbf ft but in lbf in (pounds force inches), kgf m (kilograms force metres) or Nm (Newton metres).

Often a torque wrench is calibrated with more than one set of units, but if not the following conversion factors may be useful: