THE MAKI

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

iN DATOR

IS MARK

By John F. Moor

A.M.1.R.T.E.

HAVING long been a protagonist of the use of large, high-powered engines in British heavy vehicles, I have been encouraged over the past couple of years or so by the increasing number of such vehicles that have been offered to me for test, the latest in this line being an A.E.C. Mandator Mk. V 24-ton tractive unit with 11-3-litre diesel engine. The 186-b.h.p. net output of this unit gives a particularly satisfactory overall road performance when working at 24 tons gross and the fuel consumption is nothing like as heavy as advocates of smaller engines would have us believe, over 9 m.p.g. being obtainable when cruising at around the 30 m.p.h. mark, and 8•5 m.p.g. when keeping up to the 40 m.p.h. limit.

The use of a big engine gives several advantages over and above that of helping to keep traffic on unsuitable roads flowing reasonably quickly. Performance in the upper gearbox ratios is invariably Improved, and this leads to reduced driver fatigue, whilst, as a subsidiary advantage, less-frequent gear changing must have a beneficial effect on the whole transmission line. Another very important factor is that an engine giving a power-to-weight ratio of over 7 b.h.p. per ton is rarely called upon to deliver its maximum output for long continuous periods, as occurs when too small a unit is used, so engine life benefits.

The ability to cruise comfortably at speeds of 40 m.p.h. and above is not necessarily an important advantage for operators in Great Britain, who are rarely able to make profitable use of the time saved, but fast journey times are regarded more favourably overseas, and even when running at its overseas gross train-weight rating of 32 tons (this can, in fact, be increased to 36 tons when a heavyduty rear axle is fitted) the Mandator tractive unit should be able to keep up with the pace of other heavy vehicles, with a fair chance of it using less fuel into the bargain. . Although the Mandator Mk. V as a model has been on the market for several years, the tractive unit tested was the version introduced only recently, this having the type nomenclature 2G4RA, the " 2 " distinguishing it from the original G4RA series.

The differences are by no means insignificant. The A.E.C. 2AV690 engine is now standard, this having a C.A.V. DPA distributor-type injection pump as opposed B32 to the in-line pump of the AV690 engine which was originally offered at optional

equipment. T h e 2AV590 9-6 hire engine is offered its the 2G4RA, its power output being some 50 b.h.p. less than that of the 11.3 litre unit, with a torque reduction of 87 lb. ft. A further difference between the 2AV690 and 2AV590 engines is that the former has a governed speed of 2,000 r.p.m.-200 r.p.m. higher than the other engine's. In both cases an A.E.C.

air compressor replaces the former 10-cu.-ft. equipment. Continuing down the line of the transmission, the old "ABC type" bell housing has now been abandoned in favour of one conforming to S.A.E. standards, whilst a new design of gearbox is now employed, this having six speeds as standard—top is an overdrive—and being stronger whilst more compact than the five-speed constant-mesh assembly formerly used. The gearbox has a cast-iron casing, but the selector mechanism is housed in a light-alloy cover. The primary and overdrive gears have helical teeth, the remainder straight-spur teeth, and the overdrive section is housed in a casing bolted to the rear of the gearbox.

The rear axle has been changed also, a production alteration being that the axle casing is now fabricated from two steel pressings, whereas a forging used to be employed. As before, the final-drive gearing consists of spiral-bevel and double-helical trains, but the old 9-in.-centres assembly which used to be standard is now offered only as an alternative to a lighter 8-in, unit, the weight difference being 1.25 cwt. The new pressed casing can take either set of gearing or, incidentally, the overhead-worm gears used in the double-drive bogies of Mammoth Major Mk. V models.

The A.E.C. S-cam brakes of the original Mk. V Mandator, which gave a total frictional area of 746 sq. in., have now been replaced by Girling cam units of slightly smaller frictional area but which have the advantage of

weighing less. The brakes are the same diameter as before, but the new front-brake linings are 0.25 in. wider, whilst the rears are 0.75 in. narrower. As before, 0-75-in.-thick linings are fitted at front and rear.

Yet another change to the standard vehicle specification concerns the Park Royal plastics cab. The basic design of this has not been altered in any way, but the comfort of the occupants in cold weather should be enhanced by the provision now as standard of heater units on each side of the engine cowl, only one heater having been fitted before.

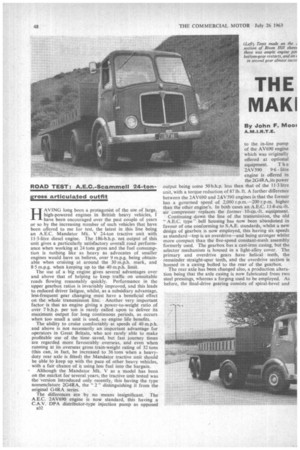

The tractive unit tested was a standard home-market model with a wheelbase of 8 ft. 1 in. The estimated kerb weight of this vehicle, with cab, is 4 tons 12.25 cwt. (the dry weight is estimated at 4 tons 5.75 cwt.), but actually the kerb weight of the test machine was 1.5 cwt. less than the estimated figure, although by the time the Scammell fifth-wheel coupling and rear wings had been added the unit's kerb weight totalled 4 tons 17 cwt.

The semi-trailer used for the laden parts of the test was a Scammell 25-ft. 6-in, tandem-axle assembly with rubber suspension, although the unladen work was carried out with a different trailer of identical mechanical specification except for the use of Dunlop Pneuride air springs in place of the rubber stacks. The rubber-sprung semi-trailer without spare wheel weighed 3 tons 8-25 cwt., the air-sprung job weighing 2.5 cwt. less The rubber-sprung semi had Dunlop RB6 tyres, whilst the air-sprung bogie had 9-00-20 (12-ply) textiles. It will be seen from the weight-distribution figures included in the data panel that the semi-trailer bogie was carrying only 11 tons 13-75 cwt., which is comparatively little above the British legal limit of 11 tons which applies to a twin-oscillating-axle back end. Had it been possible to have moved the fifth-wheel farther forward of the rearaxle centreline than the 12 in. it was, the 13-75 cwt. could have been re-distributed from the rear end of the semitrailer to the tractive-unit axles, and this would have enabled a twin-oscillating-axle semi to be used, with a subsequent payload increase of at least 15 cwt. without exceeding 24 tons gross. As it was, the outfit was carrying a few 534 pounds less than 15-75 tons, which is quite a fair figure for a combination with an engine of this output, credit for which lies mainly with the low weight of the tractive unit.

With three people in the cab the A.E.C.-Scammell was tested at a gross weight of exactly 24-25 tons, and the fuelconsumption figures obtained at this weight are good in the light of the high average speeds set up during each run. The " motorway " figure of 48-5 m.p.h. is especially good, and this average is within 10 m.p.h. of the vehicle's maximum speed, proving that the big engine really does give the ability to maintain a high cruising speed effortlessly. Similarly, the unladen tests carried out with the air-sprung semi-trailer at a total weight of 8.75 tons showed entirely acceptable fuel economy, and this tractive unit engaged on tanker work or similar applications whereby half the mileage is covered unladen, should definitely be able to return an overall consumption rate of about 10 m.p.g on normal trunk roads driving at up to 40 m.p.h. In view of the high engine power I was a little disappointed when the acceleration tests showed that well over 30 sec. were required to reach 30 m.p.h. from a standstill, but nevertheless the acceleration times recorded are very good for a 24-tonner. Fifth gear was used for the directdrive tests, which again gave very satisfactory results, and the engine and transmission were remarkably smooth all the way between 9 and 40 m.p.h. when pulling hard in this ratio. Gear-speed checks revealed maximum speeds in each of the six ratios of 4, 8, 16, 27.5, 42 and 57.5 m.p.h., so the ratio spread is seen to be entirely suited to the engine.

Although the figures obtained do not suggest that this combination is in any way unsafe, the cold-drums braking performance was not really as good as I expect from a modern 24-ton-gross articulated outfit, and I feel a lot of the blame for this must be taken by the semi-trailer, as the tractive unit's brakes appeared to be good. There was a .decided delay in the semi-trailer system, and this could be felt quite clearly when making stops from 20 m.p.h. by use of the semi-trailer-brake hand reaction valve, the maximum retardation produced being 24.5 per cent.

Single Air Servo All four brakes of the semi-trailer are actuated by a single piston-type air servo through a system of rods and levers. The power is there all right, as shown by the fact that the bogie wheels locked when making these test stops, so the problem to be tackled is clearly one of delay. Bison Hill (0.75 mile long, with an average gradient of 1 in 10-5) was used for the hill-performance tests, this being a severe incline for a 24-ton vehicle, particularly from the fade-test angle. The ascent was made in an ambient temperature of 13°C (55°F) and the engine-coolant temperature before making the climb was 67-5°C (153°F). The A.E.C. Scammell went up the hill like a rocket in the remarkably short time of 4 min. 55 sec., the ascent being spoilt only by slight exhaust hazing at times. The lowest ratio used was second, this having been engaged for 2 min. 19 sec. and except when the speed fell momentarily to 3 m.p.h. on the steepest section, a pace of 7 m.p.h. was maintained while in this gear. That the engine was working hard was indicated by the coolant temperature rising to 82.5°C (180-5°F), but the system is pressurized to 4 p.s.i, so overheating is unlikely to occur, in Britain at any rate. Export models have a 22-in, instead of a 20-in. fan.

Fade resistance was checked in the usual way by coasting down the hill in neutral and keeping the footbrake applied to restrict the speed to 20 m.p.h. The stop made at the bottom of the hill showed that the descent, which lasted 2 min. 40 sec., had reduced the maximum braking efficiency by a half, the Tapley meter reading 32 per cent at the end of the test. This was by no means all due to reduced lining efficiency or excessive drum expansion, most of the trouble being that the stop had to be made at a line pressure of 45 p.s.i.—less than half the maximum pressure—and this resulted from excessive pressure drop which in turn was caused by the front-suspension characteristics making it impossible to keep my foot steady on the brake pedal.

Unfortunately, the rate of pressure build-up with this air-pressure system is not particularly high, and it took 57 sec. with the engine running on the governor to build up the reservoir pressure from 50 p.s.i. to its maximum of 105 p.s.i. This means that once the pressure has dropped to a dangerously low figure, the driver has to be very careful to see that it has built up again before he moves his vehicle, as the build-up time is greater than is usual. Following the 32 per cent stop the air pressure was restored to over 100 p.s.i. and a further brake test carried out, this being about 2 min. after the first stop and resulting in a reading of 54 per cent, which is much more reasonable.

Gradient restart tests were made on the 1-in-6.5 section of the hill. Facing up the slope the tractive-unit handbrake and the semi-trailer air brakes were proved powerful enough to hold the outfit by themselves, but the semi-trailer parking brake would only stop rearward movement when it was pulled on with the footbrake fully applied. These three brakes behaved in exactly the same manner when the vehicle was facing down the hill also. A bottom-gear get-away was made very comfortably and smoothly using only about quarter throttle, and a second-gear attempt almost succeeded. Similarly, only about quarter throttle was needed to make a reverse restart, showing that the Mandator Mk. V has ample power in hand for operation on severe slopes. The criticism about the semi-trailer parking brake will not apply to future versions of this model, as the ratchet-type lever is to be replaced by a handwheel, which should be much more effective.

The generous engine power made this outfit most enjoyable to drive, and the good matching of engine power and gearbox ratios helped enormously also, emphasizing the advantage of engine and gearbox being designed and manufactured by the same people. The power unit tended to be a bit noisy when accelerating, but was quiet enough when cruising at a steady speed, including full-throttle work on a motorway. The gear change of this new box is really excellent, and no practice is required to get used to it— which is more than can be said for a number of gearboxes these days! The box was not quiet though, gear noise being prevalent in all the indirect ratios, including overdrive.

Because of its short wheelbase, the tractive unit was inclined to pitch a lot and the front suspension was rather harsh, but generally the ride was quite good for this class of vehicle, and remained acceptable when unladen: indeed, there was less pitching when running with an empty semitrailer, this being due to the absence of tugging at the coupling which is present when a full load is being carried. One of the main troubles with the suspension is that the roughness of the ride makes it difficult to keep one's foot steady on the brake and accelerator pedals. The steering is good despite road bumps occasionally being felt through the wheel rim, and the effort required never becomes high: this is a great help when shunting, of course. Castor action is adequate at all times. A slight fault which might have been peculiar to the test vehicle only was that some shimmy was observed when travelling at over 55 m.p.h.

The Park Royal cab has many attributes, including finish, access, roominess, all-round visibility, seating, heating and demisting, and positioning of the instruments. Vision to the rear was marred somewhat by the excessive vibration of the Magnatex 10-in. by 6.5-in, mirrors, however. Stowage space is limited to a small pocket behind the driving seat and a useful tool box built into the rear corner by the passenger seat, this box having a hinged lid. Hot-weather ventilation, although not put to the test, is probably no more than adequate, there being no hinged ventilator panels in the doors, although the heater units can be isolated from the hot-water circuit by turning off taps under the engine cowl, whereupon they will force cool air into the cab. The door windows are of the balanceddrop type, but are nevertheless not too difficult to operate. Details include the provision of one sun visor and a double coat hook, but the engine-cowl quilt—which fitted badly— is classed as an extra, whereas I feel it should be a standard fitting in view of the potential engine-noise level. For a heavy vehicle of conventional layout the engine accessibility of this A.E.C.—in common with other current A.E.C. maximum-capacity models—is good. There is the usual A.E.C. full-width hinged top panel, which swings up towards the driving seat, plus a quickly detachable panel reaching down to floor level on the left side of the cowl, and between them the two apertures give really adequate access to the fuel injection and lift pumps, the twin fuel filters, the oil-bath air cleaner, all the injectors (which are easy to remove also), the generator and the oil filler. The only difficult item to reach is the dipstick, as it lies very close to the top-panel hinge, and if a small trap were to be provided in this panel it would Aive easy access to the dipstick and the filler cap.