Lifelong shine on Charrold's Ohio vans

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

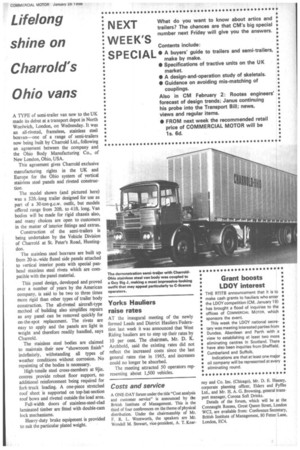

A TYPE of semi-trailer van new to the UK made its debut at a transport depot in North Woolwich, London, on Wednesday. It was an all-riveted, frameless, stainless steel boxvan—one of a range of semi-trailers now being built by Charrold Ltd., following an agreement between the company and the Ohio Body Manufacturing Co., of New London, Ohio, USA.

This agreement gives Charrold exclusive manufacturing rights in the UK and Europe for the Ohio system of vertical stainless steel panels and riveted construction.

The model shown (and pictured here) was a 32ft.-Iong trailer designed for use as part of a 30-ton-g.c.w. outfit, but models offered range from 20ft. to 41ft. long. Van bodies will be made for rigid chassis also, and many choices are open to customers in the matter of interior fittings and extras. Construction of the semi-trailers is being undertaken by the Vehicle Division of Charrold at St. Peter's Road, Huntingdon.

The stainless steel boxvans are built up from 20-in.-wide fluted side panels attached to vertical interior posts with special panhead stainless steel rivets which are compatible with the panel material.

This panel design, developed and proved over a number of years by the American company, is said to be two to three times more rigid than other types of trailer body construction. The all-riveted aircraft-type method of building also simplifies repairs as any panel can be removed quickly for on-the-spot replacement. The rivets are easy to apply and the panels are light in weight and therefore readily handled, says Charrold.

The stainless steel bodies are claimed to maintain their new "showroom finish" indefinitely, withstanding all types of weather conditions without corrosion. No repainting of the bodies is necessary.

High-tensile steel cross-members at 95gin. centres provide robust floor support, no additional reinforcement being required for fork-truck loading. A one-piece stretched roof sheet is supported on top-hat-section roof bows and riveted outside the load area.

Full-width doors of stainless-steel-clad laminated timber are fitted with double-cam lock mechanisms.

Heavy-duty brake equipment is provided to suit the particular plated weight.