COMPLETE OVERHAULS

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

IN A DAY GOOD servicing is, perhaps, of even greater importance in winning a good name for a particular make of vehicle, and retaining that reputation, than actual quality in the vehicle itself, and if there be a combination of excellent design and service which cannot be surpassed the maker has gone a long way towards the attainment of the ideal.

To the user of commercial vehicles, and particularly to the man who gains his livelihood by their operation, rapid but efficient service is essential, for time spent off the road usually means a direct loss of money, either by the failure to carry out haulage work or the neces, sity of hiring other transport. Therefore, any way in which repair work can be expedited, whilst retaining the quality of workmanship, should be heartily welcomed.

When considering the complete overhaul of a vehicle one is inclined to look upon it as work which will probably occupy at least a week, and it will, therefore, surprise many owners to learn that the service station of Morris Commercial Cars, Ltd., Soho, Birmingham, can easily carry out this work in the course of a day.

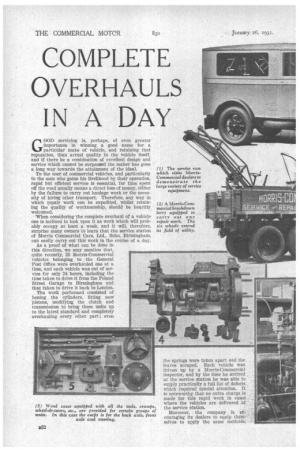

As a proof of what can be done in this direction, we may mention that, quite recently, 25 Morris-Commercial vehicles belonging to the General Post Office were overhauled one at a time, and each vehicle was out of service for only 24 hours, including the time taken to drive it from the Poland Street Garage to Birmingham and that taken to drive it back to London.

The work performed consisted of honing the cylinders, fitting new pistons, modifying the clutch and transmission to bring these units up to the latest standard and completely overhauling every other part ; even the springs were taken apart and the leaves scraped. Each vehicle was driven up by a Morris-Commercial inspector, and by the time he arrived , at the service station he was able to supply practically a full list of defects which required special attention. It is noteworthy that no extra tharge.is made for this rapid work in cases where the vehicles are delivered at the service station.

Moreover, the company is eri-. couraging its dealers to equip them: selves to apply the same methOdS;

and to help them in doing so special tools and fittings, which have been designed throughout at the MorrisCommercial works, can be supplied at moderate prices. The company has even gone so far as to equip a service van to visit its dealers for the purpose of demonstrating these appliances. This van carries two showcases in which they are displayed. In addition, boxes are being made up to contain these special tools, wheeldrawers, etc., made up into three sets —one for the back axle, front axle

and steering; one for the engine and clutch; and the third for the gearbox and transmission.

Servicing work can be carried out by appointment at any time during the day and night. For instance, a man can drive up to the station just before 5.30 p.m., the troubles will be diagnosed by an inspector and by midnight, if necessary, the cylinders can be honed, the valve seats bored out and new seats fitted, the bearings rebedded and shimmed, the clutch and transmission overhauled, new plates being fitted if required and the brakes adjusted, the vehicle being ready for service at midnight—i.e., in 61 hours. Sometimes the test and. diagnosis are carried out before a man commence the day's work, the vehicle being brought in for the necessary attention whenever he can conveniently do so.

During the one-day overhaul 11 hours is the actual working time on the vehicle, after which the engine is run-in for 3 hours with cold water passing continuously through the radiator. Cylinders have been honed out as much as 65 thousandths, and that the whole system is not an experiment is proved by the fact that already 0,000 vehicles have been treated in this way, and so far the company has only had. one definite complaint. In the event of any trouble occurring, however, a man would be at once sent to see the vehicle, and if, after examination, any fault were to be discovered in the work performed, then it would be re done free of charge; on the other hand, if the complaint proved to be unjustified the owner would have to defray any further expense.

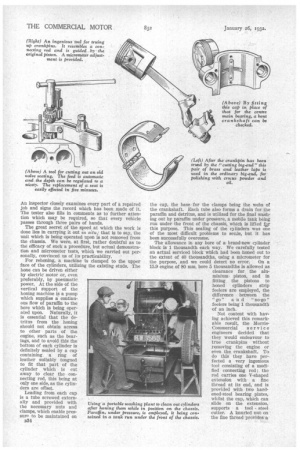

In the case of every vehicle sent' in for repair a report is submitted to the owner, who need not necessarily have everything done, but he then knows the exact condition of the vehicle. Au inspector closely examines every part of a repaired job and signs the record which has been made of it. The tester also fills in comments as to further attention which may be required, so that every vehicle passes through three pairs of hands.

The great secret of the speed at which the work is done lies in carrying it out -tn situ; that is to say, the unit which is being operated upon is not removed from the chassis. We were, at first, rather doubtful as to the efficacy of such a procedure, but actual demonstration and micrometer tests, which we carried out personally, convinced us of its practicability.

Leading from each cap is a tube screwed externally and provided with the necessary nuts and clamps, which enable pressure to be maintained on B4 the cap, the base for the clamps being the webs of the crankshaft. Each tube also forms a drain for the paraffin and detritus, and is utilized for the final washing out by paraffin under pressure, a mobile tank being run under the front of the chassis, which is lifted far this purpose. This sealing of the cylinders was one of the most difficult problems to settle, but it has been successfully overcome.

The allowance in any bore of a brand-new cylinder block is 1 thousandth each way. We carefully tested an actual serviced block which had been honed out to the extent of 40 thousandths, using a micrometer for the purpose, and we could detect no error. On a 15.9 engine of SO mm. bore 5 thousandths is allowed as clearance for the aluminium piston, and in fitting the pistons to honed cylinders strip feelers are employed, the difference between the " go " a n d " no-go " feelers being 1 thousandth of an inch.

Not content with haying achieved this remarkable result, the Morris

Commercial service engineers decided that they would endeavour to true crankpins without removing the engine or even the crankshaft. To do this they have perfected a very ingenious tool consisting of a modified connecting rod; the rod carries one V-shaped extension with a fine thread at its end, and is provided with two hardened-steel bearing plates, whilst the cap, which can slide on the extension, supports a tool steel cutter. A knurled nut on the fine thread provides a simple feed, whilst any play on the extension or the slot in the cap can be taken up by an adjustable back plate.

With ordinary use a cutter can deal with 100 journals without the need for regrinding, but as it is positioned on the crankpin and then tightened into the cap before each operation regrinding makes no difference to the accuracy of the work done. Four journals with an ovality of 3 thousandths to 4 thousandths can be trued up in half an hour, and it is obvious that the pin must have the correct relationship with the cylinder bore, because the cutter is accurately directed by the actual piston for that bore being on the tool.

The tool will easily remove flats, and in order to prove this to us one was actually filed on a crankpin to a depth of several thousandths and successfully removed in a few minutes; in fact, cuts up to 25 thousandths, with a tolerance of half a thousandth, can easily be made. The finish is very good, but for those who want it to be even better a leather-faced lap which fits into the standard big-end is provided, and this, used in conjunction with a small amount of crocus powder and oil, will result in a mirror finish. In one test

which we watched an ovality of 10 thousandths of an Inch was removed in seven minutes.

The boring out of valve seats is carried out with a particularly ingenious tool, which also clamps on to the upper face of the cylinders. Eight new seats and a; set of valves can be finished in an hour.

The cutter holder, has a fine thread and ends in a stem which fits into the valve guide, and there is a nut locking the cutter in position. On the fine thread, above the main support, is a ring cut with spur teeth and provided with a setscrew, by which it can be locked at any desired position, so that it limits the descent of the cutter to the right depth. At the side of the holder is a second spindle upon which are carried two pillions, the lower one meshing with the teeth on the adjustable ring, whilst the upper pinion has dogs meshing with similar projections on the lower pinion. At the upper part of the cutter holder is a single projection, and at each revolution this moves the upper pinion to the extent of one tooth, thus transmitting the necessary amount of feed to the cutter. The tool cannot be strained, because when the adjustable ring reaches its limit of travel the upper pinion merely slips its dogs and rises against the spring which presses it down. The finest centrifugal cast iron is utilized for the new seats, which are 4 thousandths larger than the bores made for them, and they are driven in after being coated with a sal-ammoniac solution which finally rusts them into position. We timed the process. The cutting of a valve seat takes three minutes, and the new seat was in position in four minutes 20 seconds, whilst 40 seconds were taken to cut the setting square and flush with the cylinder face. A bevel for the valve was cut in a few moments.

Amongst other appliances designed for this service work are a simple tester for the alignment of connecting rods, and a dial and micrometer device for ascertaining if a crankshaft be bent. This latter consists of a cap which is clamped in place of the usual cap of the centre bearing, and as the connecting rod is rotated the needle indicates on the dial any deflection.

The service engineers are also devising a tool to true up the centre main bearing, rhich is the one that is apt to be the fist to develop any ovality.