A NEW ONE-TON CHASSIS FROM FRANCE.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

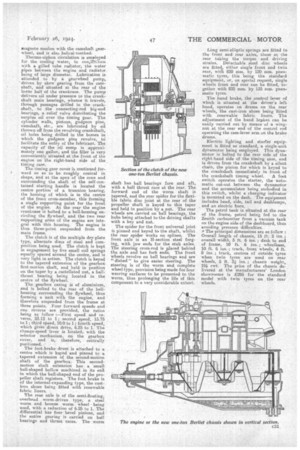

First Published Details of the Latest Product from the Berliet Works. The Specification Includes Four Speeds and Worm Drive.

TN accordance withtheir policy, of ,.....supplying a vehicle to meet every requirement, the well-known. French firm of motor manufacturers, Automobiles Pit Berliet, of Lyons, France, and 40, Saekville Street, London, W.1, are now placing on the market a commercial vehicle with a net carrying capacity of one ton, and we understand that the first examples of this chassis are now

on their way to London from the works

This chassis should he particularly suitable for fast delivery work, as it is capable of speeds in excess of 30 m.p.h., and is to be supplied by the manufacturers fitted with a iariety of bodies to suit all trades.

The frame is constructed from channel-section pressed steel, and the sidemembers are tapered in an upward direction front and rear, while the frame is also inswept at the front" from a point in line with the rear of the gearbox. Four substantial channel-section cross-members are fitted, ensuring absolute rigidity.

The engine has four cylinders, cast en bloc, and fitted with a detachable cylinder head. The bore is 80 mm. and the stroke 130 mm.., giving a rated horsepower of 15.9, although the engine develops 22 brake horse-power at 1,400 r.p.m. and 28 brake horse-power at

2,000 rpm. The pistons have three rings, all situated above the gudgeon pin which latter is locked in the small end of the connecting rod, and revolves in bosses in the piston. The big-end bearings of the connecting rods are of bronze, lined with white-metal, similarly constructed bearings being used for the three main bearings of the crankshaft. The big-end bearing caps and the front and centre main bearing caps are held in place by two bolts, the ,rap of the rear main bearing being rotained by four bolts. The exhaust and inlet valves are located on the left side of the engine and are interchangeable, being operated by a single camshaft driven from the crankshaft by heir-toothed The e gearwheel riving the

magneto meshes with the camshaft gear' wheel, and is also helical-toothed. Thermo-siphon circulation is employed for the cooling water, in conjenslion with a gilled tube radiator, the water pipes between the engine and radiator being of large diameter. Lubrication is attended to by a gearwheel pump, • driven by skew gearing from the camshaft, and situated at the rear of the lower half of the crankcase. The pump • delivers oil under pressure to the crankshaft main bearings, whence it travels, through passages drilled in the crankshaft, to the connecting-rod big-end bearings, a relief valve distributing the surplus oil over the timing gear. The cylinder walls, pistons, gudgeon pins, camshaft, etc., are lubricated by oil thrown off from the revolving crankshaft, oil holes being drilled in the bosses in which the gudgeon pins revolve, td • facilitate the entry of the lubricant. The capacity of the oil sump is approximately one gallon, and the filler is very conveniently situated at the front of the engine on the right-hand side of the timing case.

The timing gear cover is continued forward so as to he roughly conical in shape, and at the apex of the cone and surrounding the shaft of the self-contained starting handle is located the centre portion of a trunnion bearing, the housing of which is in the centre of the front cross-member, this forming a single supporting point for the front of the engine. At the rear the engine crankcase is bolted to a bell-housing encircling the flywheel, and the two rear supporting arms of the engine are integral with this housing. The engine is thus three-point suspended from the main frame.

The clutch is of the multiple dry-plate type, alternate discs of steel and composition being used. The clutch is kept in engagement by five small coil springs equally spaced around the centre, and is very light in action. The clutch is keyed to the tapered extension of the gearbox first-motion shaft, and held in position on the taper by a castellated nut, a ball. thrustbearing being located in the centre of the flywheel.

The gearbox casing is of aluminium, . and is bolted to the rear of the bellhousing surrounding the flywheel, thus forming a unit with the engine, and therefore suspended front the frame at three points. Four forward speeds and one reverse are provided, the ratios being as follow :—First speed and reverse, 23.12 to 1; second speed, 15.75 to 1 ; third speed, 10.0 to 1; fourth speed, which gives direct drive, 6.25 to 1. The change-speed lever is located,with the selector mechanism, on the gearbox cover, and is, therefore, centrally positioned.

The foot-brake drum is attached to a centre which is keyed and pinned to a taperedextension of the second-motion shaft of the gearbox. This secondmotion shaft extension has a small ball-shaped hollow machined in its ena in which the ball-shaped end of the propeller shaft registers. The foot brake is of the internal-expanding type, the castiron shoes being fitted with renewable fabric liners.

The rear axle is of the semisfloating, overhead .worm-driven type, a steel worm and bronze worm wheel • being used, with a reduction of 6.25 to 1. The differential has four bevel pinions, and the entire gearing is carried on ball bearings and thrust races. The worm

shaft has ball bearings fore and aft, with a ball thrust race at the rear. The forward end of the worm shaft is tapered, and the rear spider for the flexible fabric disc joint at the rear of the propeller shaft is keyed to this taper and held in position by a nut. The rear wheels are, carried on ball bearings, the hubs being attached to the driving shafts with a key and nut.

The spider for the front universal joint is pinned and keyed to the shaft, whilst the rear spider works on splines. The front axle is an H-section steel forging, with jaw ends for the stub axles. The steering cross-rod is _placed behind the axle and has fork ends. The front wheels revolve on ball bearings and are " dished " to give easier steering. The steering is of the worm and complete wheel type, provision being made for four wearing surfaces to be presented to the worm, thus prolonging the life of this component to a very considerable extent.

Lang semi-elliptic springs are fitted to the front and rear axles, those at the rear taking the torque and driving strains. Detachable steel disc wheels are fitted, either single front and twin rear, with 820 BIM by 120 mm, pneumatie tyres, this being the standard equipment, or, on special request, single wheels front and rear can be fitted, together with 835 ram. by 135 nun, pneumatic tyres.

The hand brake, the control lever of which is situated at the driver's left hand, operates on drums on the rear wheels, the cast-iron shoes being -fitted with renewable fabric liners. The adjustment of the hand brsakes can be easily carried out by means-of a wingnut at the rear end of the control rod operating the cam-lever arm on the brake drums,

Electric lighting and starter equipment is fitted as standard, a single-unit dynamotor being employed. This dynamotor is bolted to the rear side of the right-hand side of the timing case, and is driven from the crankshaft by a silent chain, the pinion for which is keyed to the crankshaft immediately in front, of

the crankshaft timing wheel. A foot switch operates the starter, the automatic cut-out between the dynamotor and the accumulator being embodied in this switch, whilst a charging indicator is mounted on the dash. The equipment includes head, side, tail and dashlamps, and an electric horn.

The petrol tank is situated at the rear of the frame, petrol being fed to the Zenith carburetter from a vacuum tank on the engine side of the dashboard, thus avoiding pressure 'difficulties.

The principal dimensions are as follow : Overall length of chassis, 15 ft. 2 ins. ; overall width, 5 ft. 6 ins. ; dash to end of frame, 10 ft. 6 ins. ; wheelbase, 10 ft. 6 ins. ; track, front wheels, 4 ft. 8 ins. ; track, centres of outside tyres when twin tyres are used on rear wheels, 5 ft. 3A ins. ; chassis weight, 19 cwt. The price of the chassis delivered at the manufacturers' London showrooms is £295 for the standard model with twin tyres on the rear wheels.