AIR-COOLING THE CRANKCASE.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

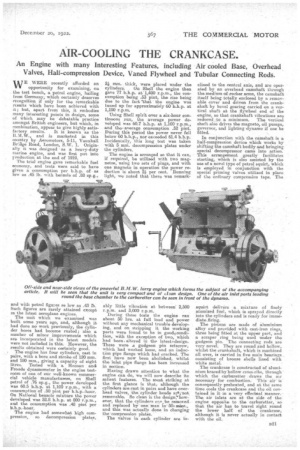

An Engine with many Interesting Features, including Air cooled Base, Overhead Valves, Half-compression Device, Vaned Flywheel and Tubular Connecting Rods.

WE WERE recently afforded an opportunity for examining, on the test bench, a petrol engine, hailing From Germany, which certainly deserves recognition if only for the remarkable results which have been achieved with it; but, apart from this, it embodies many interesting points in design, some of which may be debatable practice amongst British engineers, but which, in combination, appear to give highly aatis factory results. It is known as the li.M.W., and is marketed in this country by Aeromotors, 5-11, Vauxhall Brlage Road, London, S.W. 1. Originally it was designed as a heavy-duty marine engine, and was first put into production at the end of 1919.

The trial engine gave remarkable fuel economy, and tests were said to have given a consumption per b.h.p, of as low as .45 lb. with benzole of .88 sp.g.,

and with petrol figures so low as .43 ha. Such figures are rarely attained except in the latest aeroplane engines.

The unit which we examined was built some years ago, and, although it had done no work previously, the cylinder bores had become rusted; also a number of minor improvements which are incorporated in the latest models were not included in this. However, the results obtained were certainly good. The engine has four cylinders cast in pairs, with a bore and stroke of 120 iron. and 180 mm., giving a capacity of eight litres. Tested with a Heenan and Froude dynamometer in the engine testretell of one of our well-known commercial vehicle manufacturers, on Shell petrol of .76 sp.g., the power developed was 60.5 b.h.p. at 1,100 r.p.m., with a consumption of .50 pint per b.h.pahour. On National benzoic mixture the power developed was 52.8 b.h.p. at 800 r.p.m., and the consumption was .48 pint per The engine had somewhat high compression, so decompression plates, mm. thick, were placed under the cylinders. On Shell the engine then gave 77 b.h.p. at 1,400 r.p.m., the consumption being .53 pint, the rise being due to the fact 'that the engine was tuned up for approximately 60 b.h.p. at 1,100 r.p.m.

Using Shell spirit over a six-hour continuous run, the average power developed was 60.7 b.h.p. at 1,100 r.p.m., and the•average consumption .52 pint. During this period the power never fell below 60 b.h.p., nor exceeded 61.4 b.h.p. Incidentally, this long test was taken with 5 min, decompression plates under the cylinders.

The engine is arranged so that it can, if required, be utilized with two magnetos, -using two sets of plugs, and with one magneto in operation the power reduction is about 4 per cent. Running light, we noted that there was remark

ably little vibration at between" 2,500 r.p.m. and 3,000 r.p.m.

During these tests the engine ran about 50 hrs. at full load and power without any mechanical trouble developing, and on stripping it the working parts were found to be in goodtcondition, with the exception of two, which hod been altered in the latestr,design. These were a gudgeon pin setscrew, which had worked loose, and an induction pipe flange which had cracked. The first have now been abolished, whilst the inlet pipe flange has been increased in section.

Having drawn attention to what the engine can do, we will now describe its salient features. The most, striking at the first glance is that, although the cylinders are cast in pairs and have overhead valves, the. cylinderr heads arskenot removable. So clean is the design "however, that the cylinders ern, be removed and replaced by one. man in' 50A and this was actually done in changing the compression plates.

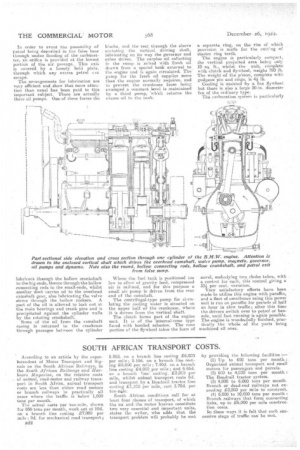

The valves in each cylinder are in

dined to the central axis, and are operated by an overhead camshaft through the.medium of rocker arms, the camshaft itself being totally enclosed by a removable cover and driven from the crankshaft by bevel gearing carried on a vertical shaft at, the flywheel end of the engine so that crankshaft vibrations are reduced to a minimum. The vertical shaft also drives the magneto, oil pumps, governor, and lighting dynamo if one be fitted.

In conjunction with the camshaft is a half-compression device which works by shifting the camshaft bodily and bringing special decompressor cams into action. This arrangement greatly facilitates starting, which is also assisted by the use of a novel type of petrol squirt, which is employed in conjunction with the special priming valves utilized in place of the ordinary compression taps. The squirt delivers a mixture of finely atomized fuel, which is sprayed directly into the cylinders and is ready for immediate.firing. The pistons are made of aluminium alloy and provided with cast-iron rings, three being fitted at the upper part, and a scraper ring being used under the gudgeon pin. The connecting rods are very novel. They are round and hollow, whilst the crankshaft, which is machined all over, is carried in five main bearings consisting of bronze shells lined with white metal.

The crankcase is constructed of aluminium braced by hollow cross-ribs, through • which the carburetter •drams the ate necessary for combustion. This air is consequently preheated, and at the same time cools the crankcase and the oil contained in it in a •very effectual manner. The air inlets are at the side of the engine opposite to the carburetter; so that. the air has to travel right round the lower half of the crankcase, although it is never actually in contact with the oil. In order to avoid the possibility of petrol being deposited in the false base through undue flooding of the carburetter, an orifice is provider" at the lowest portion of theair passage., This exii is covered by a loosely held plate, through which any excess petrol eau escape.

The arrangements for lubrication are very efficient and show that more attention than usual has been paid to this important subject. There are actually three oil pumps. One of these forces the

lubricant thlough the hollow crankshaft to the big ends, thence through the hollow connecting rods to the amall-ends, whilst another duct carries oil to the overhead camshaft gear, also lubricating the valve steins through the hollow rockers. A part of the oil is allowed to leak out at the main hearings and crank pins and is precipitated against the cylinder walls by the rotating crankshaft.

Some of the oil from the camshaft casing is returned to the crankcase through passages between the cylinder

blocks, and the rest through the sleeve enclosing the vertical driving shaft, lubricating on its way the governor and other drives. The surplus oil collecting in the sump is mixed with fresh oil drawn from a. special tank external to the engine and is again circulated. The pump for the fresh oil supplies more than the engine normally requires, and to prevent the crankcase from being swamped a constant level is maintained by a third pump, 'which returns the excess oil to the tank.

Where the fuel tank is positioned too low to allow of gravity feed, compressed air is -utilized, and for this purpose a small air pump is driven from the rear end of the camshaft.

The centrifugal-type pump for circulating the cooling water is situated on the upper half of the crankcase, whece it is driven from the vertical shaft.

The clutch forms part of the engine unit. It is of the internal-cone type faced with bonded asbestos. The corm portion of the flywheel takes the form of

a separate ring, on the rim of which provision is made for 'the cutt'ng of starter ring teeth,

The engine is particularly compact, the vertical projected area being only 10 sq.ft., whilst the unit, complete with clutch and flywheel, weighs 790 lb. The weight of the piston, compiete with gudgeon pin and rings, is 4i lb.

Cooling is assisted by a fan flywheel. but there is also a large 20-in, diameter fan of the ordinary type.

The carburation system is particularly EXT1,-r?

novel, embodying two.choke tubes, with a control for each, this control giving a 33per cent. variation.

Very satisfactory efforts have been made to utilize this engine with paraffin, and a fleet of omnibuses using this power unit is run on paraffin for periods of half an hour in slow traffic; after this time the drivers switch over to petrol or benzole, until fast running is•again possible. The engine is wonderfully finished, practically the whole af the 'parts being machined all over.