SUPERHEATERS FOR STEAM VEHICLES.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Third Article Types of Valves. Some

HEN USING SUPERHEATED steam, there are certain points in the construction of the • eylindees which require consideration. In the first place, it is not advisable to use the ordinary flat-side valve, or part of the economy of using super. heated steam will be lost. The high temperature of the steam will cause greater expansion of the metal, and a flat-side valve will be distorted and, will warp because it is tlot symmetrical in shape.

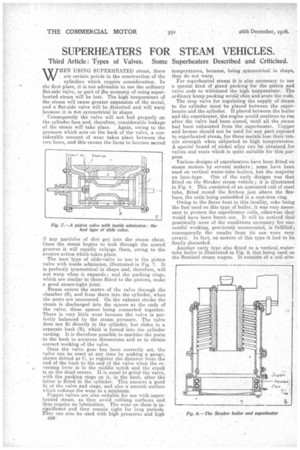

Consequently the valve will not bed properly en the cylinder face and, therefore, considerable leakage of the steam will take place. Again, owing to the pressure which acts on, the back of the valve, a considerable amount of wear takes place between the two faces, and this causes the faces to become stored if any particles of dirt get into the steam chest. Once the steam begins to leak through the scored grooves it will rapidly enlarge them, owing to the erosive action which takes place. The best 'type of slide-valve to use is the piston valve with inside admission, illustrated in Fig. 7. It is perfectly Symmetrical in shape and, therefore, will not warp when it expands ; and the packing rings, which are similar to those fitted to the pistons, make a good steam-tight joint.

Stearn enters the centre of the valve through the chamber (S), and from there into the cylinder, when the ports are uncovered. On the exhaust stroke the steam is discharged into the spaces at the ends of the valve, these spaces being connected together. There is very little wear because the valve is perfectly balanced by the steam pressure. The valve does not fit directly in the cylinder, but slides in a separate bush (B), which is forced into the cylinder casting. It is therefore possible to machine the ports in the bush to accurate dimensions and so to obtain correct working of the valve.

Once the valve gear has been correctly set, the valve can be reset at any time by making a gauge, shown dotted at C, to register the distance from the end of the bush to the end of the valve when the re , versing lever is in the middle notch and the crank is on the dead centre. It is usual to grind the valve, with the pecking rings on it, in the bush, after the latter is fitted in the cylinder. This ensures a good fit of the valve and rings, and also a smooth surface which r educes the weir to a minimum.

Poppet valves are also suitable for use with superheated steam, as they avoid rubbing surfaces and thus require no lubrication. The wear on them is insignificant and they remain tight for long periods. They can also be used with high pressures and high ea&

Superheaters Described and Criticised.

temperatures, because, being symmetrical in shape, they do not warp.

For superheated steam it is also necessary to use a special kind of gland packing for the piston and valve rods to withstand the high temperature. The ordinary hemp packing would char and score the rods.

The stop valve for regulating the supply of steam to the cylinder must be placed between the superheater and the cylinder. If placed between the boiler and the superheater, the engine would continue to run after the valve had been closed; until all the steam had been exhausted from the superheater. Copper and bronze should not be used for any part exposed to superheated steam, for these metals lose their tensile' strength when subjected to high temperatures. A 'special brand of nickel alloy can be obtained.for valves and seats which is quite suitable for this purpose.

Various designs of superheaters have been fitted on steam motors by several makers ; some have been used on vertical water-tube boilers, but the majority on loco.-type. One of the early designs was that fitted on the Straker steam vehicle ; it is illustrated in Fig. 8. This consisted of an armoured coil of steel tube, fitted round the firebox just above the firebars, the coils being embedded in a east-iron ring.

Owing to the fierce heat in this locality, coke being the fuel used on this type of boiler, it was very neees-. easy to protect the superheater coils, otherwise they would have been burnt out. It will be noticed that practically none of the conditions necessary for successful working, previously enumerated, is fulfilled; consequently the results from its use were very erratic. In fact, on motors of this type it had to be finally discarded.

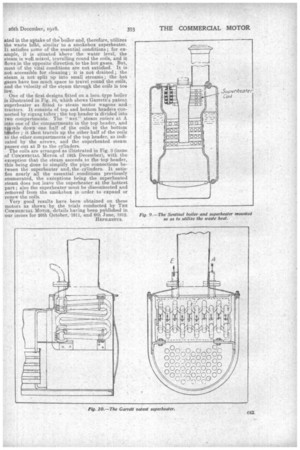

Another early type also fitted to a. verticaleavaters tube boiler is illustrated in Fig. 9, this being used on the Sentinel steam wagon. It consists of a coil situ ated in the uptake of the'boiler and, therefore, utilizes the waste helt, similar to a smokebox superheater. It satisfies some of the essential conditions ; for example, it is situated above the water level, the steam is well mixed, travelling round the coils, and it flows in the opposite direction to the hot gases. But, most of the vital conditions are not satisfied. It is not accessible for cleaning ; it is not drained; the steam is not split up into small streams; the hot gases have too much space to travel round the coils, and the velocity of the steam through the coils is too low.

One of the first designs fitted on a loco.-type boiler is illustrated in Fig. 10, which shows Garrett's patent superheater as fitted to steam motor wagons and tractors. It consists of top and bottom headers connected by zigzag tubes ; the top header is divided into two compartments. The "wet" steam enters at A into one of the compartments in the top header, and tovels down one half of the coils to the bottom

der; it then travels up the other half of the coils to the other compartments of the top header, as indicated by the arrows, and the superheated steam passes out at B to the cylinders.

The coils are arranged as illustrated in Fig. 3 (issue Of COMMERCIAL MOTOR of 19th December), with the exception that the steam ascends to the top header, this being done to simplify the pipe connections between the superheater and the cylinders. It satisfies nearly all the essential conditions previously enumerated, the exceptions being the superheated steam does not leave the superheater at the hottest part ; also the superheater must be disconnected and removed from the smekebox in order to expand or renew the coils.

Very good results have been obtained on these motors as shown by the trials conducted by THE COMMERCIAL MOTOR, details having been published in our issues for 26th October, 1911, and 6th June, 1912. Fig. 9.—The Sentinel boiler and superheater mounted