THE CAUSES OF CYLINDER WEAR.

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

The Influences of Road Dust, Lubrication, Alignment of Parts and Piston Materials.

TN RUNNING a fleet of commercial _Lvehicles, the expenditure involved in repairs and replacements gives a very good idea of the qualities of the vehicles employed and the capabilities of the engineers and drivers who are respon

sible for them. There are, of course, many chassis parts which arc bound to require replacement from time to time, such as the brake linings, but these are not usually very expensive items. The replacement of a part, such as a cylinder block, is a much more expensive

matter, and one which is liable to bold up the vehicle concerned for a considerable time. It is, therefore, well worth while to ensure, so far as possible, that cylinder wear is reduced to a minimum.

There are many contributing causes of rapid wear of the cylinders, of which one of the most important is inefficient lubrication. Owing to the heat of the eyfinder walls and the reciprocating motion of the piston, it is a difficult matter to ensure that a film of lubricant shall always separate the two. A good oil is therefore necessary and, furthermore, care should be taken that the efficiency of the oil is not reduced in ser vice. This reduction in efficiency is often brought about by fuel getting past the pistons and mixing with the oil film.

Rapid Oil Dilution.

Thus, in some cases, an examination of the oil in the sump after only 500 miles' riinning will ehow that it has become diluted with petrol to the extent of as much as 15, per cent. The viscosity or " body " of the oil is thereby reduced, and it becomes incapable of maintaining a film between the pistons and.cylinders. Tests have shown that when dilution exceeds 15 . per cent, the lubricating qualities of the oil are reduced to a dangerous extent.

Much can be done to reduce the quantity of fuel mixing with the oil. To begin with, it has been proved that dilution occurs most rapidly when the engine is cold. Consequently, if the vehicles be employed on delivery work which involves frequent stoppages, so that the power unit is always working in a relatively cold condition, steps may be taken to increase the average running

temperature Thus one may employ makeshift methods, such as blanking off a portion of the radiator, or disconnecting the fan.

A better plan, however' which has attained considerable popularity on pleasure cars, consists of fitting a thermostat, which controls the. quantity of water circulated through the radiator in accordance with the temperature. This device has the 'advantage of permitting the engine to warm up very quickly after it has been started.

Then, again, if the garage be kept at a. seasonably warm temperature in the winter, starting in the morning will be facilitated, and this alone will reduce the rate at which the oil becomes diluted with fuel.

Drivers will often prime an obstinate engine again and again by squirting petrol through the compression taps, a large amount of which gets past. the pistons and mixes with the oil.

Advantages of Air Cleaners.

Another cause of rapid cylinder wear is found in the presence of dust, which enters the carburetter with the air. This is drawn right through the induction system and into the cylinders a certain propoition mixing with the oil and form ing an abrasive compound. For this reascn, vehicles which are operated over dusty roads might well be equipped with air cleaners, which separate the dust from the atmosphere. Cleaners of this type are becoming very popular in America, most of them operating on the centrifugal, principle, in which the air is whirled round with the result that the dust is thrown out of it. Air cleaners have also been used on farm machinery in this country.

The material employed for the pistons has a considerable influence upon the rate at which the cylinders wear and, strange to say, the softer the pistons the more rapidly do the cylinders become worn away. Although this sounds contradictory, the reason as not far to seek, and will occur to anyone who has employed a lead lap and abrasive compound' in the fitting shop.

Briefly, any particles of grit or dust which mix with the 'oil film are liable to become embedded in a soft piston, so that as it goes up and down the grit is carried with it, and produces wear in the cylinders walls. For exactly the same reason, soft white-metal bearings are often more durable than a hard steel crankshaft. This is one of the reasons why commercial-vehicle manufacturers have not taken very kindly to the aluminium pis ton, because it is found to pick up particles of grit far more readily than the cast-iron variety. Then, again, if the piston during manufacture is finished off by a grinding process, it is quite possible that particles of the grinding wheel will remain embedded in the aluminium so that when it is fitted to the cylinders it serves as a lap and produces rapid wear.

Cases of Oval Wear.

In the ordinary way cylinders tend to wear oval in the direction in which the side thrust acts upon the pistons. The connecting rod being at an angle to •the cylinder axis during the greater part of the stroke, it is clear that there will be a heavy side thrust on the cylinder walls. This is often reduced on the explosion stroke by off-setting the cylinders somewhat in relation to the crankshaft.

When the cylinders are wearing in a direction at right angles to the side thrust, it is clear that some defect in alignment is causing the piston to be forced against one side of the cylinder. The trouble may be traced to a slightly bent connecting rod, insufficient clear.

ance between the piston bosses, or a crankshaft which is too flexible.

Even when all possible precaution; have been taken, the oil in the sump is bound gradually to deteriorate through the presence of fuel and dust, so that it is a good practice to drain the sump completely from time to time. It can then be flushed out with paraffin and refilled with pure, clean oil.

Whilst it is not advisable to use the dirty oil which has been drained off for lubricating other parts, economy may un• doubtedly be effected if the oil is first put through a purifying process. Apparatus is now available in which lubricant Iron' the sump can be so thorougly cleaned and cleared of all traces of fuel that it is quite fit to be used again, even in an engine.

Although not, strictly speaking, a part of the subject of cylinder wear, the scores sometimes produced in the walls by loose gudgeon pins are worthy of mention here. Despite the number and complexity of the lucking devices used to secure gudgeon pins, very few of these are sufficiently reliable to be left without attention for long periods. When ever the cylinder block i8 lifted for decarbonizing purposes the gudgeon pins should be examined.

Incidentally, many makers are DOW teeming the pia to the connecting rod instead of the piston, and it is certainly easier to provide a reliable fastening wIen this practice is adopted.

Scored cylinders can now be repaired without regrinding by special processes in which the scores are filled electrolytically. • Worn cylinders must, of course, be reground to make them truly circular, and new pistons are then necessary.

In addition t wearing oval in one direction or another when viewed from the top, the cylinder bore is apt to become tapered from top to bottom, the greatest wear taking place at the top. In some engines the top ring does not reach the top of the cylinder bore at the completion of the stroke, so that a ridge is formed on the bore in the course of time. Here a leaf might be taken from the book of the locomotive engineer, it being a common practice to counterbore the ends of steam-engine cylinders. In lorry engines fitted with detachable heads this enlargement of the bore near to the top could quite easily be effected in the course of manufacture, so that the top ring of the cylinder would just overrun the edge of the enlargement at the top dead centre. In this way no ridge would. be formed.

The question of adequate lubrication has already been mentioned, and it is clear that this is a difficult matter owing to the heat of the piston and the sliding and scraping action of the rings. Many people favonr the introduction of a certain amount of oil with the fuel, as is commonly done in the ease of steam engines. This practice, in addition to reducing the rate of cylinder wear, is also claimed to improve the working conditions of the valves.

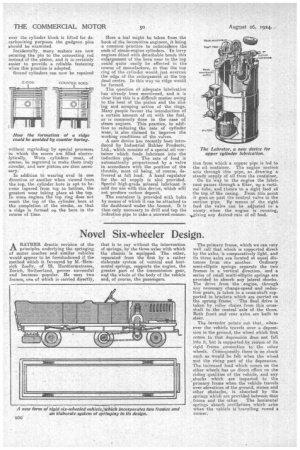

A new device has recently been introduced by Industrial Rubber Products, Ltd., which consists of a special oil container which feeds lubricant into the induction pipe. The rate of feed is automatically proportioned by a valve in accordance with the position of the throttle, most oil being, of course, delivered at full load. A hand regulator for the oil supply is alsr■ provided. Special high-grade mineral lubricant is sold for use with this device, which will not produce carbon deposit.

The container is provided with bolls by means of which it can be attached to the dashboard under the bonnet. It is then only necessary to drill and tap the induction pipe to take a screwed connec

lion from which a copper pipe is led to the oil container. The engine suction acts through this pipe, so drawing a steady supply of oil from the container.

On its way to the engine the lubri. cant passes through a filter, up a vertical tube, and thence to a sight feed at the top of the casing. From this point it goes on past the control valve to the suction pipe. By means of the sight feed the valve can be adjusted to a nicety when the engine is running, giving any desired rate of oil feed.