For DRIVERS, MECHANICS & FOREMEN.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter /shish we publish on this page all others are paid for at the rate of a penny a lute, with an allowance for photographs. All notes are edited before being published Mention. your employer's name, in confidence, as evidence of good faith. Address, D., la and E., "The Commercial Motor," 7-15, Rosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, August 30th, light your lamps at 8.54 in London, 9.17 in Edinburgh, 9.8 in Newcastle, 9.11 in Liverpool, 9.2 in Birmingham, 9.4 in Bristol, and 9.24 in Dublin.

Some Points About Steering Gears.

The sewier of the following communication has been awarded the 102. prize, this week.

[2007] "11.3.0." (Chiswick) writes :—" I have been thinking a ,goo-d deal lately about steering gears. In nearly every car one handles there is shake or play to a greater or leas extent in the steering gear. Moreover, if it is desired to correct the trouble and remove the play, there is only one way to do it: the

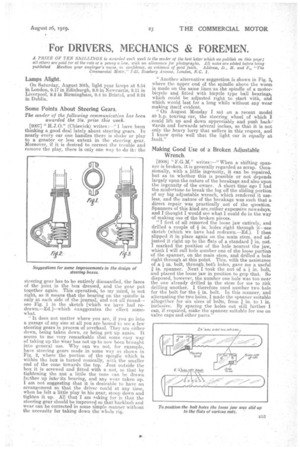

steering gear has to be entirely dismantled, the faces of the joint in the box dressed, and the gear put together again. This operation, to my mind,, is not right, as it means that the bearing on the spindle is only at each side of the journal, and not all found—. bee Fig. 1 in the sketch [which we have had redrawn.—Ed,]—which exaggerates the effect somewhat.

" It does not matter where you are, if you go into a garage of any size at all you are bound to see a few steering gears in process of overhaul. They are either down, being taken down, or being put up again. It seems to me very remarkable that some easy way of taking up the wear has not up to now been brought into general use. Why can we not; for example, have steering gears made in some way as shown in Fig. 2, where the portion of the sTinclie which is within the box is turned conically, with the smaller end of the cone towards the top. Just outside the box it is screwed and fitted with a nut, so that by tightening the nut a little the cone can he drawn further up into -its bearing, and any wear taken up. i I am not suggesting that t is desirable to have an arrangement so that the driver could at any time, when he felt a little play in his gear, stoop down and tighten it up. All that •I am :asking for is 1.hat the steering gear should be improved no that backlash and wear can be corrected in some simple manner without the necessity for taking down the whole rig.

"Another alternative suggestion is shown in Fig. 3, where the upper end Of the spindle above the worm is made on the same lines as the spindle of a motorbicycle and fitted with bicycle type ball bearings, which could be adjusted right to start with, and which would last for a long while without any wear making itself evident. "On August Monday I sat on a recent model 40 h.p. touring car, the steering wheel of which , could lift up and down appreciably and push back: Wards and forwards several inches, so that it is not only the heavy lorry that suffers in this respect, and I know quite well that the light car is equally at fault."

Making Good Use of a Broken Adjustable Wrench.

12008] " F.G.M." writes :—" When a shifting spanner is broken, it is generally regarded as scrap. Ocea. sionally, with a little ingenuity, it can be repaired, but as to whether this is possible or not depends largely upon the nature of the breakage and also upon the ingenuity of the owner. A short time ago I had the misfortune to break the lug off the sliding portion of my big adjustable wrench, which rendered it useless, and the nature of the breakage was such that a direct repair was practically out of the question. Spanners of this kind are, rather expensive nowadays, and I thought I would see what I could do in the way of making use of the broken pieces. "I first of all removed the loose jaw entirely, and drilled a couple of in. holes right through it—see sketch (which we have had redrawn.—Ed.). I then slipped it in place again on the main stem, and adjusted it right up to the flats of a standard a in. nut. I marked the position of the hole nearest the jaw, which I will call hole number one of the loose portion of the spanner, on the main stem, and drilled a hole right through at this point. This, with the assistance of a 7} in. bolt, through.both holes, gave me a useful a in. spanner. Next I took the nut of a in. bolt, and placed the loose jaw in position to grip that. So disposed, however, the number one hole was too near the one already drilled in the stem for me to risk drilling another. I therefore used number two hole for the bolt for the i in. bolt. In this manner, and alternating the two holes, I made the spanner suitable altogether for six sizes of bolts, from g in. to 1 in. inclusive. By spacing the holes out still further I can, if required, make the spanner suitable for use on valve caps and other parts."