UK MAKERS LEAD FIELD

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Few Europeans can compete with the superb bodybuilding seen at the Temperature Controlled Storage and Distribution Show this week • Despite filthy weather, visitors to the third Temperature Controlled Storage and Distribution Exhibition, held at Sandown, Surrey, this week, were left in no doubt concerning the efficiency and hygienic standards of equipment available for carrying perishables. They were also impressed by the quality of the services offered.

Exhibitors from seven countries gave the event an international flavour, but an attendance of 1,200 — key personnel — did not truly reflect the extent of the industry across Britain.

Few Continental bodybuilders turn out the volume necessary in order to provide superb high-specification bodies at competitive rates, but it seems that British manufacturers can provide models of equal excellence while providing an engineering flexibility that is unbeatable.

Several British reefer makers expressed concern over Britain's lack of positive legislation to match the 2.6m width limit in Holland and 2.55m in Belgium and France (France may soon extend it to 2.6m). This places the British held at 2.5m with a possible increase to 2.55m, particularly international hauliers, at a serious disadvantage when trying to carry 24 pallets in thin-walled semitrailers.

A 2.6m width limit would allow ade: quate insulation and enough room inside for the air circulation necessary to keep the perishables fresh, the industry argues.

The British industry is still payload conscious, particularly up to the 7.5 and 16.26-tonne sectors, and there were signs of an increasing use of eutectic refrigeration equipment on small to medium-weight trucks.

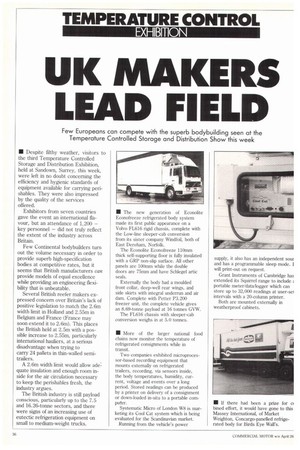

• The new generation of Econolite Econofreeze refrigerated body system made its first public appearance on a Volvo FL616 rigid chassis, complete with the Low-line sleeper-cab conversion from its sister company Windfoll, both of East Dereham, Norfolk.

The Econolite Econofreeze 110mm thick self-supporting floor is fully insulated with a GRP non-slip surface. All other panels are 100inm while the double doors are 75mm and have Schlegel artic seals.

Externally the body had a moulded front collar, deep-well rear wings, and side skirts with integral underrun and air dam. Complete with Petter P3.200 freezer unit, the complete vehicle gives an 8.69-tonne payload at 16 tonnes GVW.

The FL616 chassis with sleeper-cab conversion weighs in at 5.0 tonnes.

• More of the larger national food chains now monitor the temperature of refrigerated consignments while in transit.

Two companies exhibited microprocessor-based recording equipment that mounts externally on refrigerated trailers, recording, via sensors inside, the body temperatures, humidity, current, voltage and events over a long period. Stored readings can be produced by a printer on delivery of a consignment or down-loaded in-situ to a portable computer.

Systematic Micro of London W8 is marketing its Cool Cat system which is being evaluated for the Scandinavian market.

Running from the vehicle's power supply, it also has an independent sou/ and has a programmable sleep mode. I will print-out on request.

Grant Instruments of Cambridge has extended its Squirrel range to include portable meter/data/logger which can store up to 32,000 readings at user-se intervals with a 20-column printer.

Both are mounted externally in weatherproof cabinets.

• If there had been a prize for a bined effort, it would have gone to this Massey International, of Market Weighton, Concargo-panelled refrigerated body for Birds Eye Wall's. Iassey International's Leyland engired twin-steer Freighter 16.17 chas:akes care of likely axle overloads ing from diminishing loads while the nsfrig compressor/condensor refriged system has a split of eutectic hold and fan blown evaporator. This cornwith the integrated body of one:e lightweight panels to maintain low peratures with multi-drop deliveries.

With a turnover exceeding 21 million onth and a new rigid body shop retly opened, Carrymasters of Doncascontinued growth reflects customer fidence in its products.

'his latest in ATP class C refrigerated n-trailer from the Doncaster-based ipany is built on its patent mini-beam ssis. Its bulkhead and rear frame are le of stainless steel while the 50mm dated side panels have an alloy outer which gives a smart mirror finish. ls well as BPW air suspension with and variable height for docking, interlift, Holland 1,500kg rollaway tailwas also fitted.

Ls control unit has a memory feature naintain the platform's attitude and

sets of controls. These are on the ssis, in the body and — foot operated s — on the edge of the platform. 'ogether with a Carrier Thunderbird :zer the trailer tares out at 8,500kg a plated 33,000kg urw.

The appearance of an insulated and rigerated Seven-5 Liner completes alloy's range of jig-built bodies for 7.5niers. Although it is still only in the notype stage, advance tests show that ;hould achieve ATP class C certificaa.

The non-HGW reefer, which was sold Truckrent and is now leased back to alloy, is built to the 5.2m x 2.3m x [standard size which will fit any of the ?ular 7.5-tonne GVW chassis. Where co models are specified, the body length will reduce by 23cm to take account of the slightly shorter chassis.

The Congleton-based company will now look at jig-built 7.3m bodies for 16-tonners, initially using lightweight Tautliners with four floor options.

Boalloy's 12.2m Insuliner semi-trailer has also been updated with a new sealed, modular floor, more thermally efficient curtains and stainless steel side runners and rear frame.

• The refrigeration equipment produced by Sanden Sankyo for the Suzuki Super Carry SK410 is also suitable for the Bedford Rascal.

Thermovan of High Wycombe is now producing a chilled or frozen specification body that gives a 480kg payload on that chassis.

The body, which can have 80 or 100mrn Klegecell insulation between aluminium panels, is 1.85m long, 1.35m wide and 1.25 high and has an anodised interior.

With the Sanden YTU-18UL enginedriven compressor and evaporator temperatures of —20°C can be achieved.

Stainless steel hinges and triple door seals with balance tube are included in the 27,355 (excluding VAT) retail price. An eutectic beam system is optional.

• Massey International's new C-Series design of ATP class C insulated body derives its structural strength from a series of steel reinforcing ribs embedded in the 75mni GRP sandwich side panels.

Its one-piece hardwood covered floor with 100mm of polyurethane insulation has no heavy underfrarne; instead, the body is mounted directly to the vehicle chassis on steel runners. This, says Massey, allows the body to absorb dynamic loads and lets the flexing come from the floor rather than the side walls.

The first production model (as shown) built at Market Weighton for Dawson Rentals is a 7m-long version on a Volvo FL6 rigid chassis and has a payload of around eight tonnes. Four more are being built and Massey is planning to begin producing 7.5-tonne models for non-HGV operation.

• Among Ratcliff of Welwyn, Hefts, exhibits was its new Stowlock column lift, available with overhead or underfloor beam for use on vans or trucks and in 1,000 or 1,500kg capacities.

A new 12 or 24 volt electrically operated hydraulic ram valve is used. The lift platform is held securely in its travelling position by a new stowage lock. Sales livery can be presented on the one-piece GRP underpanel.

Ratcliffs own design of retractable cantilever tailift (above) made in its French factory was also on show for the first time. The 1,500kg lift slides away on chassis-mounted rails 1.6m under the body when not in use. It will become available during mid-summer.

• The latest insulated curtainsider from Barking company Tilt Techniek, the Chilfast, uses curtains supplied by Rolands of Holland. These consist of synthetic fibre blankets between two pvc-coated polyester sheets, which are said to resist heat penetration to a high degree.

A single-piece Ferroplas roof panel is used and supported on each side by the Tiltec Rolling Post system, which can move one metre each side of centre.

Brush seals behind the top pelmet and thermal breaks at the corner posts provide thermal insulation that will help to hold the temperature down to —6°C.

Roland also supplied the ExSpray mudflaps made from a stiff synthetic mesh on a solid reinforced backing and made by Enka Industrial Systems. These are said to exceed the British Standards AU 200/2 requirements and each one carries the kite mark.

A tandem-axled flat-bed semi-trailer ExSpray kit costs £135 and a tri-axled one 2200.

• The only new-model Transit at the show had this Supercool 10/50 refrigerated body system from Bedwas Bodyworks of Newport, built for Ready Roasted Chickens of Aberdare.

With its bonded sandwich panel construction and GRP non-slip floor, the Hubbard 460H freezer unit will maintain temperatures of 3°C (chilled) for carrying pre-cooked food, such as meat pies or dairy produce.

Build time is 19 days including five days for the freezer unit.

• Refrigerator manufacturers took the opportunity to launch several new units, among them Ipswich-based Hubbard's latest the 486 one-piece over-cab freezer with external evaporator.

Now in its 25th year, Petter of Hamble celebrated by launching two new widermount units. One is the P3-100U that provides 3.3kW at —20°C, and the P6100U that gives 4.65kW at 20°C both in a 30°C ambient temperature. The latter is primarily for large trailers.

Thermo King of Galway, Republic of Ireland, also had a pair of new units to present to the industry. The LND model, with its 495cm3 compressor, is designed for close-coupled drawbar trailers or chilled use on 12m semitrailers.

iii This lightweight 3m refrigerated body from Coolfreeze Refrigeration of Manchester uses Transfrig eutectic equipment for an operating temperature range of —23°C to 4°C and has been sold to Sutcliffe Catering South for use at Heathrow's Terminal 4.

The same type is being used by several health authorities for the cook/chill system of preparing meals.

Using the Zepro KZ-140 aluminium column lift, which weighs just 160kg, it allows a payload of 1,400kg.

IN Don-Bur of Longton, Staffordshire's new temperature controlled body, aptly called the PolaBur, uses its own Slide-aSide design, but with insulated curtains and nylon brush seals top and bottom. Roof and bulkhead have 100mm of sulation along with the floor which alsc has a 25rnm Safodeck ply facing.

An extra inner layer provides an ant vandal option.

• The only drawbar combination sh( was built on a Volvo FL7 and Task airsuspended trailer at Craven Tasker's Garstang works for Salford Van Hire tc hire to Fast Fresh Distribution.

Both bodies are insulated for carryin, total of 26 pallets of flowers, fruit, vegl tables and pre-packed salads.

• Examples of Manchester-based G Cooltrucks stylish bodywork, developec last year with the help of the Government's design scheme, included this Roadrunner mounted box body in the al tractive livery of Pullman Foods.

The seamless GRP interior is hand la minated 'in-situ' creating hygienic condi. tions for carrying fresh, chilled or froze foods.

With its Frigobloc RR1012 freezer ur with recessed evaporator this was one five such vehicles for Pullman to go wit] the seven insulated Ford Escort vans.

These were converted for carrying chilled foods using the new Temework Polarpac refrigeration system of plastic entectic plates capable of —25°C. Plate: are removable to change the degree of refrigeration to suit the goods carried.