Last week we omitted the serial number of the Hints

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

given. These should have been :-4.—Removing and Replacing Albion Brake Shoes ; 5.—The Care of Chains; 6.—Lifting Leyland Cylinders; 7.—Lubrieating Leyland Carden Dies.

8.—Cutting Oil Channels in Bearings.

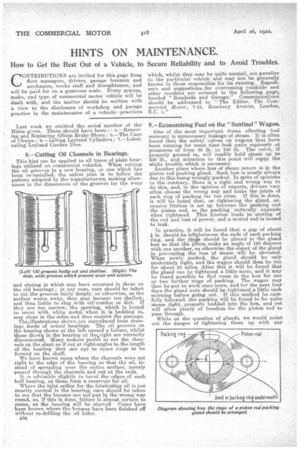

This hint can be applied to all types of plain bearings utilized on commercial vehicles. When cutting the oil grooves in a new bearing, or one which has been re-metalled, the safest plan is to follow the pattern adopted by the manufacturers, making allowances in the dimensions of the grooves for the wear and closing in which may have occurred in those on the old bearings ; in any case, care should be taken to cut the grooves fairly deeply, as otherwise, as the surface wears away, they may become too shallow, and thus liable to clog with oil c residue or dirt. If they are too narrow, the spewing, which is bound to occur with white metal when it is bedding in, may close in the aides.and thus restrict the passage.

The,ilhistrations shown;are reproduced from drawings made of actual bearings. The oil grooves on the bearing shown at the left caused a failure, whilst those shown in the bearing at theliight are correctly dimensioned. Many makers prefer to cut the channels on the slant as if cat at right-angles to the length of the bearing they are apt to cause rings to be formed on the shaft.

We have known cases where the channels were cut right to the edge of the bearing so that the oil, instead of spreading over the entire surface, merely passed through the channels and cut at the ends.

It is advisable slightly to bevel the edges of each half bearing, as these form a reservoir for oil.

Where the inlet orifice for the lubricating oil is not exactly central in the bearing, care should be taken to see that the brasses are not put in the wrong way round, as, if this is done, failure is almost certain to ensue, as the bearing will be starved Cases ha,ye been known where the brasses have been finished off without re-drilling the oil holes.

B34

9.—Economizing Fuel on the "Sentinel" Wagon.

One of the most important itema affecting fuel economy is unnecessary leakage of steam. It is often found that the safety valves on wagons that have been running for some time leak Quite copiously at pressures of from 80 lb. to 100 113.. The valve, '-if properly ground in, will readily hold steam up to 230 lb., and attention to this point will repay the slight trouble which is necessary.

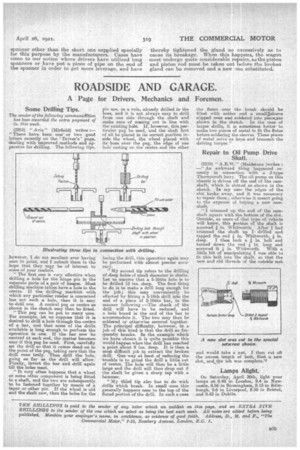

Another place where loss of steam occurs is in the piston rod .packing gland. Such loss is nearly always due to this being wrongly packed. In spite of opinions to the contrary, there is a right and wrong way to do this, and, in the opinion of experts, drivers very often choose the wrong way and make the joints of each ring of packing far too close. If this is done, it. will be found that, on tightening the gland, excessive friction is set up between the packing and the piston rod, as the packing naturally expands when tightened. This friction leads to scoring of the rod and loss of power, and a Scored rod is bound to leak.

In practice, it will be found that a gap of about

in. should be leflbetween the ends of each packing ring, and the ring. should be placed in the gland box so that the 'joints make an angle of 180 degrees with one another, as otherwise the object of the gland in preventing the loss of steamwill be obviated. When newly packed, the gland -should be only moderately_ tight, and the wagon should then be run for about 50 miles. After this it will be found that the gland can be tightened a little more, and it may be found possible to find room in the box for one or two further rings of packing. The wagon may then be put to work once more, and for the next four days the gland nuts should be tightened a little each morning before going out. If this method be carefully followed, the. packing will be found to be quite steam tight, properly bedded into the box, and yet will allow plenty of freedom for the piston rod to pass through.

While on the question of glands, we would point out the danger of tightening these np with any spanner other than the short one supplied specially for this purpose by the manufacturers. Cases have come to our notice where drivers have utilized long spanners or have put a piece of pipe on the end of the spanner in order to get more leverage, and have

thereby tightened the gland 'so excessively as to cause its breakage. When this happens, the wagon must undergo quite considera,ble repairs,aa the piston and piston rod must be ,alken out before the broken gland can be removed and a new lne substituted.