THE LATEST 21 TON ORWELL ELECTRIC.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

Two Independent Motor Units, Each Embodying Double-helical Reduction Gearing. Improved Tipping Gear.

THE ELECTRIC vehicles made by Ransomes, Sims and Jefferies, Ltd., at. Orwell Works, Ipswich, have achieved an enviable reputation, particularly amongst municipal engineers, and

the latest production from the Orwell works will certainly not detract from this reputation.

The 21 ton Orwell electric, with front wheel drive, has been on the market for some little time, but the comparatively new type, in which two direct current motors are secured to the frame and embody the reduction gearing, was first seen at the Commercial Vehicle Show at Olympia last October and is not so well known as its prototype.

In this vehicle several important changes have been incorporated, and the motor units have been rendered most accessible. The frame is of pressed channel-section steel, tapered to the front but otherwise straight, and provided with three channel-section cross-members and two angle-section members to support the motors. Following the Most recent practice, the frame is bolted throughout, as rivets are extremely liable to work loose. At the fiont of the frame is a stout wooden buffer, which can be replaced, in case of breakage, with the minimum of labour and expense.

C14 Semi-elliptic springs of the ordinary type and with bronze-bushed eyes, are provided for both front and .rear axles. The former is a drop forging, but the rear axle is machined from the solid. The spring brackets are particularly Burnt, and the pivot bars pass right across the chassis.

The wheels are of the built-up pressed steel type, with a cast-steel nave on to which the felloe is riveted, and they bear a resemblance to those employed on the Thornycroft chassis.

The two motor units are totally enclosed and are positioned one at each side ef the chassis. Each has a removable water-tight aluminium cover, which allows for easy access to the commutator and carbon brushes. The motor units are bolted direct to the frame sidemembers and to the angle-section crossmembers previously mentioned.

Unlike the larger Orwell eleetries, the motors of this vehicle are series wound, and incorporated with each is a singlereduction, double-helical internal gear, situated at the inner ends of the armature shafts, where it is totally enclosed and runs in grease.

Roller chains to the rem' wheels provide a further reduction. Each motor unit is starved at the front, and is provided with a radius rod.

There are several interesting points about the controller, which is of the horizontal drum type, and is situated

under the floorboards in a dustproof casing. Two forward running speeds and a reverse, are provided, and the contoiler is operated by a lever working in a gate change quadrant and interlocked

with a pedal connected with the drum of the rheostat. In order to prevent burning of the commutator segments, the operating lever carrno€ be moved until the electric circuit is broken by depressing the cut-out pedal.

.,The socket for the charging plug is situated in front of the controller gate, so that if the charging plugis in position the operating lever cannot be moved into gear, In the same way, the plug cannot be inserted if the lever happens to be in the wrong position. One of the speeds is obtained by putting the motors in series, whilst, the other is obtained by putting them in parallel.

When Ironclad Exide accumulators are employed, each battery consists of 40 cells giving 110 volts, but in the case of alkaline accumulators 60 cells. are employed. The complete battery is installed beneath the driver's seat, and the battery box projects back into the body about 1 ft., for which purpose the body is suitably recessed.

On the dashboard is a combined ampere-hour meter, voltmeter, and ammeter. Incidentally, each chassis is equipped with a hub-cap hodorneter, by which the mileage can be checked.

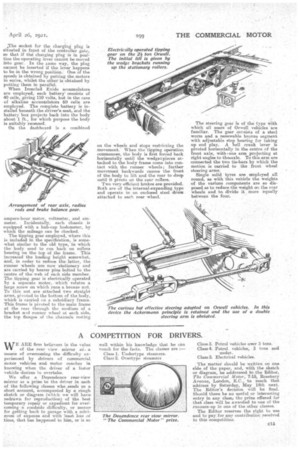

The tipping gear employed, where this is included. in the specification, is somewhat similar to the old type, in which the body used to run back on rollers bearing nn the top of the frame. This increased the loading height somewhat, And, in order to reduce the latter, the runner wheels are now stationary and are carried by hearer pins bolted to the eentre of the web of each side member. The tipping gear is electrically operated by a separate motor, which rotates a large screw On which runs a bronze nut. To this nut are attached two straight arms, pivoted to the bottom of the body, which is carried on a subsidiary frame. This frame is pivoted to the main frame at the rear through the medium of a bracket and runner wheel at each side, the top flanges of the channels resting on the wheels and stops restricting the movement. When the tipping operation commences, the body is first forced hack horizontally until the wedge-ipieces attached to the body frame come into contact with the runner wheels; further movement backwards causes the front of the-body te lift and the rear to drop until it pivots oh the rear rollers.

Two very efficient brakes are provided. Both are of the internal-expanding type and operate in an enclosed steel drum attached to each rear wheel. . The steering gear is of the type with which all users of Orwell vehicles are familiar. The gear coPsists of a steel worm and a renewable bronze segment with adjustable step bearing for taking up end play. A bell crank lever is pivoted horizontally in the centre of the front axle, with one arm projecting at right angles to theaaxle. To this arm are connected the two tie-bars by which the motion is carried to the front wheel steering arms. Single solid tyres are employed all round, as with this vehicle the weights of the various components are so disposed as to reduce the weight on the rear wheels and to divide it more equally between the four.