A Scheme to Use Steam

Page 22

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Bolsover-Rodgers System for Converting Petrol Engines to Run on Steam Raised in a Coal or Coke-fired Boiler, by Replacing a Part Of. the Existing Cylinder Head by a Suitable Number of Steam

Cylinders

T .

HE culmination of several years' research work is seen in a new conversion plan which enables ordinary internal-combustion engines to be run on steam. Among the claims made for the scheme is that this power medium results in better pulling at low speeds, whilst it gives greater &xi bility and, of course, less noise. Other

important points are that there is no ,alteration to the transmission or electrical equipment, including the dynamo and fan -drive. An advantage is. that the steam system can remain in circulation while the vehicle is stationary, so that a quick restart can be made, even after standing for several hours.

According to the makers' claims, a light vehicle/of 8-10 h.p., converted to -steam and running on good-quality coke nuts of fin, mesh, will cover 18. miles at a cost of not more than a penny. Most standard makes of British and American vehicle petrol engines are suitable for direct conversion by the Bolsover-Rodgers system.

The alterations effected in the case of a four-cylindered unit are not excessive. The existing cylinder head is

I

removed, together with two of the pistons and connecting rods. Two special single-acting steam cylinders _ are then fixed to the block, over the remaining pistons, which now function as cross-heads, the neW pistons and rods being fixed to them. Over the two unused cylinders half the old head

is replaced. The existing camshaft, adapted for steam conversion, works the .poppet valves of the new steam ,. cylinders. • One modification in connection with the camshaft is to gear it to run at crankshaft-speed. Cant contours are also changed. Of course, the system is not tied to two cylinders. On a six-cylindered petrol unit, three could be adapted for steam.

The boiler is of the mono-tube forced-circulation, type. Feed water enters, through a series of flat spiral coils in the uppermost part of the boiler, is pumped down through the series and passes into a large helical coil surrounding the fire zone. In the helical coil steam i3 generated, it being superheated by passing hrough further flat spiral coils positioned below the feed-water-heating series. Coke is fed to the firing zone through a chute in the centre of the top of the boiler casing. All the coils are wound from annealed steel tube and the tube assembly is tested to 3,000 lb. per sq. in.

Under the Bolsover-Rodgers patents, a neat system of servo-operated hydraulic damper' control has been evolved, control being by thermostat. and ,power being provided by the feeds water pressure. When the steam temp perature reaches a predetermined point, about 750 degrees F., water, under pressure, flows from a small storage chamber and acts on a diaphragm or piston by means of which the damper is Closed. This reduces the flow of air to the fire. As a result the steam temperatirre will drop below 750 degrees F. Then -the water pressure is released

from the damper servo-motor by the action of the control valve, and the damper is opened up again by means of a spring. Reaction in steam generation is quick, because the boiler is of the flash type. Sensitive control is afforded by the master thermostat, the action of which is governed by the average temperature of the steam inside the boiler, By this system overheating of the boiler coils is prevented. The makers state that it will function all day and every day without any attention. Steam temperature can be kept at any desired point and the thermostat can be set to give variations from 500 to 800 degrees F. The flow of feed water (and consequent steam pressure maintained in the boiler) is regulated by a spring control valve, which keeps the boiler pressure steady. Recent' bench-tests of a converted engine having two 44.5-mm. cylinders and a stroke of 89 mm. (276 c.c.) produced output readings of 4.6 b.h.p. at 1,000 r.p.m., 6.2 b.h.p. at 1,500 r.p.m.

and 6.5 b.h.p. at 3,000 r.p.m. Of these figures, the first represents a b.m.e.p. of 210 lb. per sq. in.

From this trial it may be inferred that a 1-litre engine would develop 17-24 b.h.p. This compares reasonably with petrol performance, the differences being lower power (on petrol) at low

\r.p.rn., but a rise of output continuing well beyond the 3,000 r.p.m., which is virtually the peak speed of the steam

engipe. , Consumption is stated to be 3 lb. per b.h.p.-hr. and the firebox capacity is 1 cwt. Coke or anthracite can be used.

Forced draught is employed to obtain and maintain the necessary fur nace temperatures, and for this pur pose there is a steam ejector in the chimney. Exhaust steam feeds this, the rest being condensed in the existing radiator. Gross water consumption is 14 lb. per b.h.p.-hr. and it is estimated that about' half of this could be recovered.

An approximate figure for the weight of a boiler—with fuel and water—for developing 30 b.h.p. is 31 cwt.

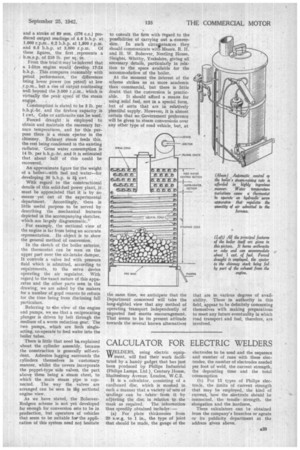

With regard to the constructional details of this solid-fuel power plant, it must be appreciated that it is by no means yet out of the experimental department. Accordingly, there is little useful purpose to be served by describing the mechanical features depicted in the accompanying sketches, which are largely diagrammatic.

For example, the sectional view of the engine is far from being an accurate representation. Its object is to show the general method of conversion.

In the sketch of the boiler exterior, the thermostat can be seen on the upper part over the air-intake damper.

It controls a valve fed with pressure fluid which is admitted, according to requirements, to the servo device operating the air regulator. With regard to the exact nature of this appa ratus and the other parts seen in the drawing, we are asked by the makers for a number of gopd reasons to refrain for the time being from disclosing full particulars.

Referring to the view of the engine and pumps, we see that a reciprocating plunger is driven by belt through the medium of a worm reduction gear. The two pumps, which are both single. acting, co-operate to feed water into the boiler tubes.

There is little that need be explained about the cylinder assembly, because the construction is generally self-evi dent. Asbestos lagging surrounds the cylinders themselves in customary manner, whilst the covers incorporate the poppet-type side valves, the part above these being a steam chest, to which the main steam pipe is connected. The way the valves are arranged can be seen in the sectional engine view.

As we have stated, the BolsoverRodgers scheme is not yet developed far enough for conversion sets to be in production, but operators of vehicles that seem to be suitable for the application of this system need not hesitate

to consult the firm with regard to the possibilities of carrying out a conversion. In such circuipstances they should communicate with Messrs. R. H. and H. W. Bolsover, Nestling House, Sleights, Whitby, Yorkshire, giving all necessary details, particularly in relation to the space available for the accommodation of the boiler.

At the moment the interest of the scheme strikes us as more academic than • commercial, but there is little doubt that the conversion is practic able. It should afford a means for using solid fuel, not in a special form, but of sorts that are in relatively plentiful supply. However, it is almost certain that no Government preference will be given to steam conversions over any other type of road vehicle, but, at the same time, we anticipate that the Department concerned will take the long-sighted view that any method of operating transport independently of imported fuel merits encouragement. That seems to be its present attitude towards the several known alternatives that are in various degrees of availability. Those in authority in this field, appear to be definitely concerning themselves with making preparations to meet any future eventuality in which road transport and fuel, therefore, are involved.