Lengthening the Life of the Chassis

Page 74

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

Few Parts that have Suffered Wear or Damage from Mishap Cannot Now be Repaired or Replaced Eco, nomically, owing to the Efforts of the Numerous Concerns Devoting Their Activities to the Needs of Maintenance Engineers T0 construct a vehicle which would run efficiently for a predetermined mileage and would then be worn out in every, item of its composition is no new ambition of designers. Were such a scheme practicable, the repairer and the maker of replacement parts would be out of business.

In actual fact, signs of wear in some component always become apparent before any indication that its life is drawing to a close appears in another. As a result, the owner of the vehicle does not hesitate to rectify the faults of the more-quickly wearing parts as the need arises.

By this means the depreciation of the chassis is retarded, and it may be that the method adopted to combat the initial wear' is such that the life of the unit affected is more than doubled. For example, to rectify worn valve seatings, a seat of hard durable metal may be inserted. The probability is that this endures for a longer period than the original seating formed in the iron of the cylinder block.

Similarly, if a centrifugally cast liner, be used to repair a worn cylinder bore, it is more than likely that the same thing occurs. This applies also to other parts of the chassis, notably brake drums.

Methods of Rejuvenation.

The purpose of this article is to review briefly the methods that may be employed to rejuvenate chassis which, through accident or age, have depreciated in respect of their efficient functioning, dealing with the items that are usually the most prone to sutler.

Largely due to its complexity, but also because of its high number of reciprocating parts, the engine is the component to which the largest number of concerns, specializing in this form of work, has devoted its activities.

Dealing first with the cylinder liners which are available, the British Piston Ring Co., Ltd., markets its Brimol liner of cast iron with austenitic structure for conditions under which an engine is being constantly stopped and started and never gets properly hot. It

c2,13.

is capable of withstanding corrosive influences. This concern has also developed a material called Brivadium for cylinder liners, which requires no heat treatment.

A centrifugally cast liner of nickelchrome iron, named Nicroloy, is produced by the C.M.D. Engineering Co., Ltd. Whilst exceedingly durable, it is easy to machine.

Hardness and toughness are qualities claimed by Messrs. C. L. Jones for their molybdenum centrifugally cast, corrosion-resisting liner. A hardened steel liner is a speciality of the Laystall Motor Engineering Works, Ltd.

The Brico concern has developed a piston ring, made from its Brilybdenum alloy for severe conditions. An ingenious ring, which incorporates a double coil, is the Clupet made by the Clews Petersen Piston Ring and Engineering Co., Ltd. It is claimed to prevent

leakage at the gap.

Two forms of piston are main pro ducts of the C.M.D. concern. Both carry the name Covmo. One is an ovalground solid-skirt piston of Lo-Ex alloy and the other, the Mark SS, a straightsided piston with a fully split skirt.

Lightweight cast iron and Arcaloy aluminium-alloy pistons are Laystall products. Wellworthy Piston Rings, Ltd., make a big range of both pistons and rings; one of the most popular types among the latter is the Simplex ring, which incorporates a flexible, but non-springy cast-iron ring, and an inner spring-steel expander, whilst an interesting piston product is the Welflex split-skirt model which has recently been much improved in efficiency.

Satisfactory Seat Renewal.

Owing to certain early difficulties in securely fixing an inserted valve seat in position some operators are doubtful of the wisdom of this form of repair. There is now no need for any uncertainty about its reliability, and a number of concerns is supplying inserts and carrying out the operation of fitting them with complete success. One of the leading makers is the Sheepbridge Stokes concern, producer of Centrilock seatings There are countless ways in which the welder can assist the maintenance engineer, but the latter is well advised to entrust intricate jobs only to the expert in this highly skilled work. Pioneer of automobile welding, Barimar, Ltd., handles large numbers of damaged parts, including cylinder blocks and heads with worn or cracked seatings, scored bores or other form of fault. Another direction in which this company employs scientific welding is the building up of crankshafts, camshafts, etc., having worn journals.

Messrs. C. L. Jones, undertake a variety of welding operations, among which may be mentioned the repair of frames, brackets, axles, gears, gearboxes, crankcases, crankshafts, cylinders and road wheels. • General welding and the extensive repair of crankshafts are also a speciality, of the Laystall concern, although it is, perhaps, more widely known in connection with its Nitralloy process of lining worn brake drums.

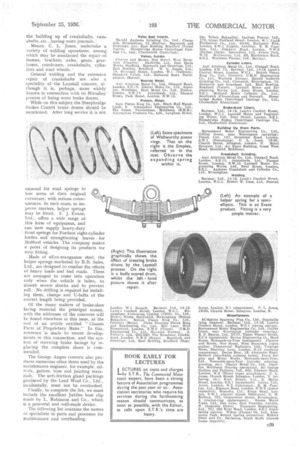

While on this subject the Sheepbridge Stokes Centrit brake drums should be mentioned. After long service it is not unusual for road springs to lose some of their original curvature, with serious consequences. In such cases, to improve matters, helper springs may be fitted. F. J. Evans, Ltd., offers a wide range of this form of equipment, and can now supply heavy-duty front springs for Fordson eight-cylinder lorries and strengthening leaves for Bedford vehicles. The company makes a point of designing its products for easy fitting.

Made of silico-manganese steel, the helper springs marketed by B.E. Sales, Ltd., are designed to combat the effects of heavy loads and bad roads. These are arranged to come into operation only when the vehicle is laden, to absorb severe shocks and to prevent roll. No drilling is required for installing them, clamps and U-bolts of the correct length being provided.

Of the many makers of brake-shoe facing material the principal names, with the addresses of the concerns will be found elsewhere in this issue, at the end of an article entitled " Chassis Parts of Proprietary Make." In this, reference is made to recent developments in this connection, and the system of renewing brake facings by replacing the complete shoes is commended.

The George Angus concern also produces numerous other items used by tha maintenance engineer, for example, oilseals, gaiters, hose and jointing materials. The anti-friction gland packings produced by the Lead Wool Co., Ltd., incidentally, must not be overlooked.

Finally, to complete the list, we must include the excellent Jubilee hose clip made by L. Robinson and Co., which is a powerful and well-made device.

The following list contains the names o f specialists in parts and processes for maintenance and overhauling.