11 BODYWORK

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

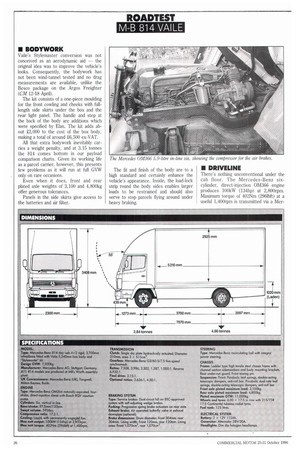

Vaile's Stylemaster conversion was not conceived as an aerodynamic aid — the original idea was to improve the vehicle's looks. Consequently, the bodywork has not been wind-tunnel tested and no drag measurements are available, unlike the Besco package on the Argos Freighter (CM 12-18 April).

The kit consists of a one-piece moulding for the front cowling and cheeks with fulllength side skirts under the box and the rear light panel. The handle and step at the back of the body are additions which were specified by Elan. The kit adds about .22,000 to the cost of the box body, making a total of around .26,500 ex-VAT.

All that extra bodywork inevitably carries a weight penalty, and at 3.15 tonnes the 814 comes bottom in our payload comparison charts. Given its working life as a parcel carrier, however, this presents few problems as it will run at full GVW only on rare occasions.

Even when it does, front and rear plated axle weights of 3,100 and 4,800kg offer generous tolerances.

Panels in the side skirts give access to the batteries and air filter. The fit and finish of the body are to a high standard and certainly enhance the vehicle's appearance. Inside, the load-lock strip round the body sides enables larger loads to be restrained and should also serve to stop parcels flying around under heavy braking.