Lighter and Bc

Page 40

Page 41

Page 42

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

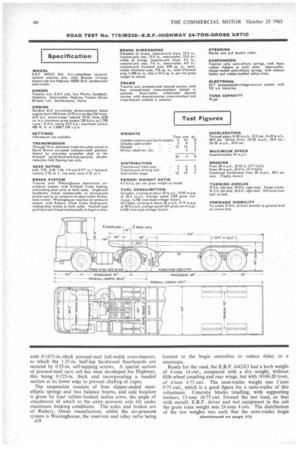

ENGINE powers are going up, but chassis weights are going down—well, sometimes at any rate. One of the latest examples of this is the E.R.F. 640X3 24-ton tractive unit, which was announced in September of this year. This new model, with set-back front axle, replaces an earlier 64GX tractive unit, and the most important difference between the two models lies in the weight saved in the newer version.

Much of the saving results from use of the new Kirkstall double-reduction driving axle, and this axle endows another important advantage in that its increased efficiency consumes less engine power and so helps to give remarkable fuel economy: a run made over a difficult 32-mile stretch of trunk road produced a fuel figure of 10-65 m.p.g. when cruising at about 30 rn.p.h., and this has been bettered only once—in this journal's tests—by a British 24-ton artic with an engine of over 9-litres capacity.

This new E.R.F. has a further, and more obvious, advantage over its predecessor in respect of its cab, the 1962-designed LV plastics-panelled assembly being standard, whilst in general terms of ride and handling the tractive unit has few equals in this country. The only power unit available in this model is the Gardner 6LX 10-45-litre 150-b.h.p. (gross) diesel, and this was shown on test to be sufficiently powerful to take the outfit, which was running at 24.2 tons gross, over a 1-in-5 gradient.

Braking efficiency was shown to be good also, although a certain amount of the credit here must be taken by the " no-hop " bogie of the Highway semi-trailer used during the tests. When stopping from 30 m.p.h. the outfit came to rest in 56-0 ft. without any of the wheels locking at all, whilst fade resistance under " suicidal " hill-descent conditions was shown to be first-class.

An ingenious feature of the tractive unit's braking system is that the linkage between the single-pull handbrake lever and the driving-axle brakes includes a pull valve by which means the semi-trailer brakes are applied also. This saves a2.6 the driver having to wrestle with a multi-pull tractive-unit brake and a separate hand-reaction valve for the semitrailer brakes.

The 64GX3 has a basically straightforward chassis layout, with 8-0-in. by 3-0-in. by 0-25-in, chassis side-members in standard form, but with the option of 0-3125-in.-thick side-member pressings for heavy-duty applications. The frame assembly is bolted, and the set-back of the front axle results in a front overhang of 4 ft. 7.125 in. Indeed, because of the rather big front overhang, the fifth-wheel coupling had to be mounted 15 in. ahead of the driving-axle centreline in order to accommodate the 26-ft. length of the Highway semi-trailer, but this proved to be no disadvantage at all, and helped the braking balance and the handling characteristics. Although the semi-trailer followed standard S.M.M.T. practice so far as positioning of the fifth-wheel kingpin and the support legs was concerned, there was still a minimum of 3.5 in. clearance between the front of the legs and the tractive-Unit's rear wing when turning, whilst clearance between the headboard of the semi-trailer and the back of the cab was a clear 2 ft.

Long semi-elliptic grooved-leaf springs, the rear springs being underslung, form the very satisfactory suspension system of the 64GX3, the steel springs working in conjunction with Aeon rubber auxiliary springs at front and rear. The front axle is a Kirkstall 4-ton assembly, with the steering controlled by Manes cam and double roller gear with a ratio of 28-5 to 1. The steering column has no support stay at its upper end, a tapered outer tube being employed instead to reduce steering-wheel shake.

The new rear axle is between 2 and 3 cwt. lighter than the Kirkstall overhead-worm unit which would otherwise have been employed, whilst another advantage is that the central pot is much smaller, so that ground clearance is improved. The axle has spiral-bevel primary reduction gears, with hub-mounted epicyclic secondary trains, these hub gears having a reduction ratio of 4 : I. A Kirkstall limited-slip differential is standard, and this will improve traction under adverse surface conditions.

There is a choice of four axle ratios: 5.26, 5.88, 6.35 and 7.38 to 1, and the test vehicle had the 6-35 axle, which gave the outfit a maximum speed of approximately 45 m.p.h. and, as already recorded, the ability to surmount a 1-in-5 gradient. Alternatively, an Eaton 19800 two-speed axle with electric gear shift can be specified, this having ratios of 4.87 and 6-63 to 1. This would give approximately the same gradient performance, but improved acceleration and a maximum speed approaching 60 m.p.h., but the single. speed double-reduction axle is adequate for most normal haulage conditions.

Although the only engine available in this chassis is the 6LX 150-b.h.p. unit, there is a similar 64G tractive unit which has the smaller Gardner 6LW 112-b.h.p. diesel, and when this is fitted the optional axle to the Kirkstall doublereduction unit is an Eaton 18802 two-speed assembly with ratios of 4.5 and 6-14 to 1 or 5.14 and 7-02 to 1. Personally, I doubt whether there is anything to gain at all from use of this smaller engine apart from a weight reduction of about 100 lb and slightly lower initial purchase price; I do not think that there is likely to be any gain whatsoever in fuel economy, Whilst obviously performance would be well down.

There is a choice of four gearboxes on the 640X3, all of which are of David Brown manufacture. The test vehicle had the 657 six-speed overdrive-top box, which is undoubtedly the most suitable one for use behind the Gardner 6LX, but alternative to this, and presumably for use with the (,LW, are 557-type directand overdrive-top boxes, which have five speeds, and the TR557 10-speed overdrive-top assembly, ,which is essentially the standard 557 box with a two-speed auxiliary section.

Kirkstall S-cam brakes are employed at front and rear, these being actuated through a Westinghouse air-pressure system with diaphragm-type brake chambers. The circuit is split, so that the driving-axle brakes have their own circuit whilst the front-axle and semi-trailer brakes are worked off the other circuit. The control valve is the neat new Westinghouse Delta valve, which is mounted on the side of the chassis frame, behind the cab, so that it is readily accessible in the event of attention being required.

The reservoir for the air-pressure system consists of a single tank with a dividing bulkhead, giving separate capacities of 615 and 992 cu. in., and, as already stated, the single-pull handbrake controls the semi-trailer brakes also.

According to the specification, 10.00-20 (14-ply) tyres on B.7-0-20 wheels are standard, but the test vehicle had the optional 9-00-20 (14-ply) equipment, which is perfectly adequate for operation at 24 tons gross, whilst there is a further alternative of 11.00-20 (I4-ply) tyres for heavy-duty applications.

The cab itself is the now-familiar LV-type, which is noted for its fine appearance and good interior appointments. The tractive unit tested had a Bowyer-built assembly, but this is scheduled to go out of production around the middle of November, future vehicles to have cabs of Jennings manufacture now that this company belongs to E.R.F. Ltd. The future Jennings cabs will be similar in appearance to the present design but will have a deeper windscreen.

The Highway trailer used for the test was a model I had not come across before, being type 1602R, with 12-in.-deep rolled-steel channel-section main members. There is an alternative type —model 1602P—with 15-in. pressed-steel channel members, and this weighs about 3 cwt. less than the version with rolled members. The semi-trailer gives every appearance of being a particularly robust assembly, with 0.1875-in.-thick pressed-steel full-width cross-bearers, to which the 1.25-in, half-lap hardwood floorboards are secured by 0-25-in, self-tapping screws. A special section of pressed-steel rave rail has been developed for Highway, this being 0.125-in, thick and incorporating a beaded section at its lower edge to prevent chafing of ropes.

The suspension consists of four slipper-ended semielliptic springs and two balance beams, and axle location is given by four rubber-bushed radius arms, the angle of attachment of which to the axles prevents axle lift under maximum braking conditions. The axles and brakes are of Rubery, Owen manufacture, whilst the air-pressure system is Westinghouse, the reservoir and relay valve being e28 located at the bogie centreline to reduce delay to a minimum.

Ready for the road, the E.R.F. 64GX3 had a kerb weight of 4 tons 14 cwt., compared with a dry weight, without fifth-wheel coupling and rear wings, but with 10-00-20 tyres, of 4 tons 4-75 cwt. The semi-trailer weight was 3 tons 9-75 cwt., which is a good figure for a semi-trailer of this robustness. Concrete blocks totalling, with supporting timbers, 15 tons 16-75 cwt. formed the test load, so that with myself, E.R.F. driver and test equipment in the cab the gross train weight was 24 tons 4 cwt. The distribution of the test weights was such that the semi-trailer bogie

loading was rather high, at 12 tons 15.25 cwt., and had the weights been-further forward the

driving-axle load would have been nearer the 8-ton mark. However, the relatively light driving axle loading was not to induce ' dangerous wheel locking, so no harm was done. The smoothness of the outfit's retardation performance has already been commented on, and an indication of the very small amount of delay in the system is shown by the fact that Tapley-meter maximum-retardation readings averaging 61 per cent were being obtained, this figure being very close to the overall retardation recorded by measuring the stopping distances from each of the test speeds. When making the handbrake stops the very good figure of 38.5 per cent was obtained from 20 m.p.h., indicating the value of linking the driving-axle and semi-trailer brakes to the same control.

Acceleration tests showed the sort of performance which I have normally obtained with the 6LX engine—sure but steady. There was insufficient road to enable times to be taken up to 40 m.p.h., but this is usually the case with 24-ton vehicles tested in this country with a power-to-weight ratio of little more than 6 b.h.p. per ton gross. The engine and transmission behaved very sMoothly during all these acceleration tests and indiVidual gear speeds noted while going up through the box were 7, 10, 15,22,33 and 45 m.p.h.

The quoted fuel consumption figures were obtained over the usual E.R.F. test route, which is 32 miles long and starts and finishes in Sandback passing through Middlewich, Mere Corner and Holmes Chapel. This is not an easy course, so the two figures recorded in the data panel are good in view of the conditions, and the average speeds are almost identical to those obtained in May with the very much lighter Perkins-engined 64P four-wheeler indicating that the 64GX3 can maintain as high an average speed as smaller vehicles under equal circumstances.

Over 1-in-5 Slope Mow Cop on the Cheshire-Staffordshire border, was used for the hill-climbing and brake-fade tests, this slope being 0-85-mile long, with an average gradient of 1 in 9 and a 1-in-5 section half-way 4; the really steep 1-in-13-75 slope at the very top of the hill was nol attempted! The ascent was made in an ambient temperature of 18°C. (65'F.), and the 8-minute 55-second climb caused the temperature of the engine coolant in the radiator header tank to rise from 64°C. (147°F.) to only 65°C. (149F.). The system is pressurized to 4 p.s.i., which raises its boiling point to 106.6°C. (224fF.).

Bottom gear was used for a total time of 7 minutes 45 seconds; and on the 1-in-5 gradient the road speed fell to about 4 m.p.h., although the rest of the climb in this ratio was made at approximately 6 m.p.h., almost on the engine governor. I must admit that for a few seconds I had my doubts as to whether the outfit would get over the 1-in-5 hump, but the engine pulled like a trojan, and once over this section all was plain sailing. There was no exhaust smoking.

For the fade-resistance test I drove the outfit down Mow Cop in neutral at 15 m.p.h., and this descent lasted 3 minutes 8 seconds. At the bottom of the hill I made a full-pressure stop from 20 m.p.h., and this produced a Tapley-meter reading 'of 50 per cent, showing an efficiency drop of only 0-11g—as near a fade-free performance on a test of this severity as I can recall.

Gradient restart tests were made on a 1-in-8 part of Radnor Hill. Facing up this slope the handbrake held the outfit with ease, Whilst flit:Semi-trailer ratchet-type parking brake also was powerful enough to hold the combination by itself. Following these tests 'a bottom-gear restart was made, but slight clutch roughness made it difficult to get away smoothly. Facing down the hill, again the tractiveunit handbrake (with the assistance of the semi-trailer brakes, of course) held the outfit, hut the semi-trailer park brake only just prevented forward motion—obviously it was in need of adjustment. A reverse restart was made comfortably, despite reverse having a higher ratio than bottom gear..

The usage of air caused by linking the tractive unit handbrake to the semi-trailer brakes was noted several times during these restart tests. On each occasion I had had cause to use the handbrake several times, and the resulting pressure drop caused the semi-trailer brakes to be .auto-: matically applied by the relay emergency valve, that being.

what the valve is there for! Forgetting this, however, I tried several times to get away without letting the air pressure, build up again, and this did not make for smooth restarts either.

The F.R.F. 640X3 is very pleasant to drive, although I would prefer to see the gearchange lever mounted slightly. further forward relative to the driving seat, or at least the top of the lever cranked so that the knob does not lie behind the level of the driving seat when in second, fourth, fifth and reverse. Considering the size of the engine, the noise level inside the cab is not at all bad, although a quilt would reduce this still more.

The tractive unit steers very well indeed, and there is good castoi action, even when running without .a semitrailer, although this-never causes the steering to be heavy. The suspension characteristics were no worse than on any other short-wheelbase tractive unit, and far better than on many. The brakes are smooth and powerful, but the pedal action is a little sensitive.

The Bowyer cab mounted on the test chassis did not quite come up to the high standard of finish and fitting as that on the 64P chassis tested earlier this year, but even so it is still far and away above average for a British heavy. vehicle. •Little detail points about it that need rectification include the heater outlet an inch or two away from the accelerator pedal, which would not only heat up the driver's right foot to an undesirable degree, but has the additional disadvantage that the knob on the outlet flap lies very close to the pedal, and sometimes impedes movement of the foot when casing of the throttle.. I have a ripped right shot to prove this. And I wish A.C. could provide a radiator filler cap with softie decent finger grips on it instead of knurls which are virtually useless. These, however, are relatively minor criticisms of an otherwise very good vehicle and one which undoubtedly meets the needs of many British heavy-haulage operators. The E.R.F. 64GX3 looks right and is right, and with the growing popularity of articulated-vehicle working in this country there is no doubt that this model will prove to be one of E.R.F.'s best sellers. The basic chassis price of the 64GX3 as tested is £3.150. The cab price is additional, and is in the region of £300. The Highway 1602R semitrailer has a list price, in the form tested, of £1,457, so the complete outfit as tested comes out at under £5,000.