There is no Finality in Motor Design.

Page 4

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

The Commercial Vehicle Chassis Considered from the User's Point of View.

By a Well-known Fleet Manager.

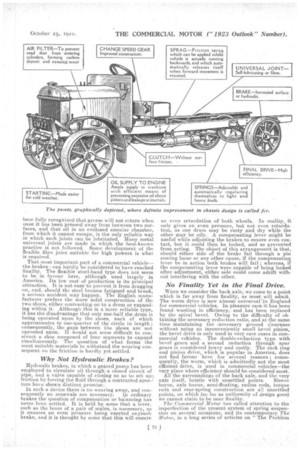

FROM a user's point of view, it is extremely doubtful whether we shall ever arrive at what may be called practical perfection. In some of the simpler classes of machines we seem to have arrived at a point where improvements have stopped, but in the motor, which is necessarily a complicated mechanism from which so much is expected, we seem to be far from what may be considered finality. Even taking the machine as it stands, without outlining what we may expect in the dim future, there are many points still very imperfect and undecided. In these remarks we are, of course, confining ourselves entirely to the commercial vehicle. To make our argument clear we propose to . run through the .entire machine from front to rear, to point out existing defects and, wherever possible, to suggest or outline some means of overcoming them. The use of automatic starters on commercial vehicles should become general, but it is considered hardly likely to do so because the owner seldom has to start the engine himself. If he had to do this, in all probability things would be different. As matters stand, therefore, cranking is likely to be the method for some time. It is well known that many commercial vehicles have to stand in very cold places and often in the open at night. In the morning, much labour is expended and time wasted in getting a start. In spite of this; how little has been done to facilitate the starting of such engines. Costly devices such as self-starters can hardly be expected, and, moreover,. with a really cold engine of large dimensions, the present-day starter and its battery are not suited to the task. Simple devices are known, but not fitted, sonic of which would hardly increase the cost to any appreciable amount. A pocket, cast integral with the inlet pipe, in which a piece of paraffin soaked rag could be put and lighted to warm the pipe has been found to answer well.

As regards the engine and the four-stroke cycle upon which it operates, we have no criticisms or suggestions to offer, as the present type is the only cycle which has Droved itself to be reliable up to now. The details of many engines are, however, capable of improvement from a user's point of view. Lubrication systems are, in many cases, none too good. The idea of limiting the amount of oil in the crankcase to prevent smoky exhaust is a dangerous plan in a machine •which has to be handled by more or less untrained persons.

Controlling the Supply of Oil.

Ample oil should be allowed to be splashed about in the crankcase, and efforts made to limit the amount which can rise up the walls of the cylinders by suitable means such as baffles, scraping rings or internally expanded pistons. The indicator which shows the presence and circulation of oil is often in such a place that it can easily be overlooked by the driver, and serious trouble will follow any shortage of oil or stoppage of circulation should it not he noticed.. The best known means of preventing escape of oil at the rear journal are not general and are only to he found on certain models. Unfiltered air is generally allowed to pass into the engine, bringing with it any particles of grit it may contain. It is true that the roads in most districts are now tarred and that dust is not to be found in such quantities as in the past. In spite of this, there must always be a certain amount flying about which will

enter the cylinders with the air unless checked. It is well known that the so-called carbon deposit in the cylinders is largely composed of road dust, which might easily have been prevented from entering the cylinder had some means been adopted fOr that purpose. The cleaning out of cylinders to remove carbon would seldom be needed if the air were cleaner. The piston and the cylinder walls form a slide which is of such a nature that it is very susceptible to even the finest 'grit. With the free entrance of unfiltered air, the surfaces in_ contact are almost as badly off as they were working in. the open, and wear of pistons and cylinder walls can hardly be wondered at. Further than this, a certain amount of fine grit passes the pistons and mixes with the oil that lubricates the bearings.

Clutch Engagement Can be Improved.

Although much has been done to improve the clutch, it is still far from perfect. In heavy vehicles it is almost wonderful that any success should have been attained with such a crude means of connecting the drive as the usual friction clutch provides. Considering that a heavy mass has to he put in motion by the engagement of a rapidly revolving shaft with a stationary one by means of friction of two surfaces, it is surprising that such good results have been obtained. When one sees some six or ten tons of solid matter jumped from a standstill into movement by means of a fierce clutch, it is not to be wondered at that trouble should be experienced. It is not, as sonic might imagine, the torque of the engine alone which has to be reckoned with; but the kinetic energy stored up in the flywheel; which exerts what may be Jescribed as a hammer blow on all parts of the transmission.

In many other mechanical devices where power has to be dissipated, such as the recoil of heavy guns and, in a smaller degree, the force of a slamming spring door, all surface frictional arrangements have been found to fail and have given place to a pneumatic or hydraulic device in which the power is absorbed by the friction of a fluid being forced through a contracted aperture. We feel that until some such plan is adopted we shall never have a perfect clutch. Such clutches have been made and tried, but only in a feeble way. Surely, what can be accomplished successfully in the checking of a spring door should not be impossible in the more scientific motor vehicle.

Few will agree that the present arrangement of change speed gears is satisfactory, or that it entirely fulfils the purpose for which it is needed. If anyone doubts this statement, he has only try go for ride on an ordinary bus or lorry with a driver of less than average ability, and to look over the scrap-heap of a repair shop which undertakes the overhauling, of commercial vehicles. Efforts have been made to provide something better, and in some cases not without success. They have, however, not received much encouragement. Only an optimist could say that we have reached finality in this matter.

In the smaller vehicles the flexible fibre joint-has proved a success, and seems to have overcome all the troubles, but with the larger types we. are not yet out of the wood ; trouble is still with us.

In the case of joints in which metal surfaces engage each other under great pressure, it is absolutely noces' sary that a good film of lubricant should be main tamed between the •surfaces. It has for some time

been. fully recognized that grease will not return when once it has been pressed away from between two sur, faces, and that oil in an enclosed annular chamber, from which it cannot escape, is the only reliable way in which such joints can be lubricated. Many metal universal joints are made in which the 'best-known practice is not followed. Some development of the flexible fibre joint suitable for high powers is what is required.

That most important part of a commercial vehicle— the brakes—can hardly be considered to have reached finality. The flexible steel-band type does not seem to be in favour here, although used largely in America. Its low cost of production is its principal attraction. It is not easy to prevent it from dragging on, and, should the steel become fatigued and break, a serious accident may happen. The English manufacturer prefers the more solid construction of the two shoes, either contracting on to a drum or expanding within it: Although this is a more reliable type, it has the disadvantage that only one-half the drum is being operated upon by the shoes, each of which approximates to one-quarter of the circle in length ; consequently, the gaps between the shoes are not operated upon. It would not seem difficult to construct a shoe composed of four segments to expand simultaneously. The question of what forms the most suitable materials to withstand the wearing consequent on the friction is hardly yet settled.

Why Not Hydraulic Brakes?

Hydraulic brakes, in which a geared pump has been employed to circulate oil through a closed circuit of pipe, and a valve capable of closing so as to set up friction by forcing the fluid through a contracted aper-. turn have shown distinct promise.

In such a device there is no wearing away, and con sequently no renewals are necessary. In ordinary brakes the question of compensation or balancing has never-been settled. It is held by some that a lever, such as the beam of a pair of scales, is necessary, as it ensures an even pressure being exerted onpach brake, and it is thought by some that this will ensure

art even retardation of both wheels. . In reality, it only -gives an even pressure, but not even retardation, as one drum may be rusty and dry while the other may be oily. A compensating lever might be useful while adjusting the brakes to ensure even contact, but it could then be locked, and so prevented from acting. The object of this arrangement is that, should either side of the brake fail through a phi coming loose or any other cause, if the compensating lever be in action both brakes will fail ; whereas, if the compensating lever were capable of being locked after adjustment., either side could come adrift without interfering with the other.

No Finality Yet in the Final Drive.

When we consider the back axle, we come to a point which is far away from finality, as most -will admit. The worm drive is now almost universallin England for commercial vehicles. In pleasure cars it has been found wantino-° in efficiency, and has been replaced by. the spiral bevel. Owing to the difficulty of oh taming the necessary reduction ratio, and at the same time maintaining the necessary ground clearance without using an inconveniently small bevel pinion, the bevel drive is only used in very rare cases in commercial vehicles. The double-reduction type with bevel gears and a 'second reduction through spur gears is considered heavy and costly. The rack ring and pinion drive, which is popular in America, does not find favour here for several reasons;, consequently, the worm, which is admittedly not the most efficient drive, is used in commercial vehicles—the very place where efficiency should be considered most.

All the surroundings of the hack axle, and the very axle itself, bristle with unsettled points. Sleeve borne, axle borne, semi-floating, radius rods, torque rods and rear-spring construction are all unsettled points, on which (so far as uniformity of design goes) we cannot claim to be near finality,

The Commercial Motor has called attention to the imperfection of the present system of spring suspension on several occasions, and its contemporary The Motor, in a long series of articles on "The Problem

• of Suspension," has brought the matter prominently to light, with the result that many of the most competent engineers have given their views. The result of the combined discussions seems to bring out the following points :—

That the contemplation of the problem from the point of view of a vehicle running over an obstacle raised from the road surface, Such as a brick, was wrong. What we have to deal with is the running over pot-holes.

(2) That more harm is done when running light than when loaded. (I) That springs should be adjustable, so that they can be tuned up to the class of lead and body they have to carry. • (4) Further than this, they should automatically adjust themselves, so that when running light the load is carried on springs which yield •• freely, and at the same time become stronger as the load is increased.

Until we get nearer to these ideals we can hardly claim to have reached finality.

The All-desirable Sprag Brake.

The ordinary sprag is as far from an ideal device as anything can be. It is probably about the crudest of all parts appertaining to a modern vehicle. Even in its crude form it is not always present. All who have had actual experience know that difficulty is experienced by drivers, and that narrow shaves do occur on steep hills. Such troubles usually come unexpectedly, and it is too late then to let the sprag down with safety. Cases of vehicles jumping the sprag are not unknown, and, if the owners of such vehicles habitually drove them, they would soon ask for something better than the present arrangement. In The Commercial Motor of January 24th there was illustrated a new idea in sprags, which consisted of a • supplementary brake which could be applied while the

vehicle was actually in motion backwards, without injury, and which would automatically release itself when forward motion was resumed.

Sufficient attention does not seem to have been given in design to the possibility of misuse and neglect by careless or inexperienced persons. That neglect and carelessness will always have to be reckoned with should be fully appreciated by the designer, and every arrangement made so that the result of such treatment will not seriously harm the machine. Wherever possible, the lubrication of such parts as gearboxes and differential cases should be so arranged that the main supply of oil lubricates all the surrounding parts. The fewer the parts to be lubricated and the more accessible they ate, the more likely are they to receive attention. One of the most experienced users of commercial vehicles, who had a very large fleet under his control, has been heard to say, when taking up the matter of some failure of a vehicle to stand up to its work :—" I know that this trouble is the result of neglect on the part of those responsible for maintaining the vehicle, but what we want is a vehicle that 1vill stand a good deal of neglect."

We are continually hearing of vehicles -which have run for what seems an extraordinarily long distance without costing anything excepting for trivial parts, and at the same time we have other complaints, often relating to the same make of vehicle, of excessively high cost of upkeep. We are quite aware that in both eases the vehicle is the same, and that it is merely a matter of handling, and that the user is entirely to blame. In spite of this, such complaints do not tend to enhance the name of the makers, although they may not be to. blame, and do not help the commercial motor as a whole. It is therefore, the duty of all designers, so far as possible, to arrange matters 'so that, even if the machine be not handled in the best possible manner, the parts which suffer should not be expensive, and that damage can be put right at trifling cost.