TIPPING GEAR INNOVI AND MODIFICATIONS.

Page 12

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

TG the uninitiated one of the surprising features of the Olympia Show was the large number of tipping gears which were exhibited. Many of these are extremely novel in their action, but the general laandeney appears to be towards simplification. in the past many gears of this 'type were comprised of a great many parts, ill-protected, and in many cases having inadequate -bearing surfaces. The result was that considerable trouble was experienced with jamming and undue wear. For many years the chief efforts of designers were concentrated on the improvement of end-tipping gears only„ but recently there have been great developments in connection with gears which would permit tipping to either side and to the rear.

The first really successful efforts to produce tipping gears of this type were seen at the 1920 Commercial Vehicle Exhibition, where they were exhibited on the British Berna, Saurer, and Eagle Engineering stands. During the past year, however, great progress has been made, and this type of gear bids fair to supersede the simple end-tipping variety. The three-way gear presents many advantages over it prototype, particularly where tipping is required to be performed in confined areas or along narrow roads. Take road-making, for instance. It is often necessary to tip road material to the side of a narrow road so that it will not obstruct the traffic, or even the passage of the tipping wagon itself, whilst at other times the same vehicle may be required to deposit its load at the rear. Formerly, these two operations necessitated two vehicles, but now one vehicle can perform the two tasks. .

A development of the threeway gear is the all-round tipping gear, whereby the body can be pivoted round on its own axis and tipped at any point, the body being capable of turning through some 270 degrees. Unfortunately, no examples of this type were to be seen, but one was shown at the, Paris Salon, and another has been produced by a well-known manufacturer of steam wagons.

The simplicity and the ease with which hydraulic tipping gears can be installed is making this type most popular. Owing to its construction, it is far easier to protect from damage owing to the entry of dirt and moisture, and the operating pump can be fitted in any position most convenient to the manufacturer. It is also quite possible to connect the pump on the vehicle with a 'tipping ram on the trailer which it draws. One application of this principle was shown on the F.W.D. stand, the provision of a simple three-way cock enabling the pump to be connected either to the hydraulic cylinder of the vehicle or that of the trailer.

An interesting form of Bromilow and Edwards three-way gear is applied to to the F.W.D. lorry. In this gear a single ram is carried on trunnions so that it can swivel in either direction The body is held in position by four locking bolts, two of which are released at a time, so that the body is free to swivel on the other two. The hydraulic pump is driven by a friction wheel from the flywheel, and the ram. is situated amidships. A novelty about the gear fitted to this vehicle is that a flexible connection from the pump is taken to 'a similar tipping ram on the trailer, so that, by means of a three-way cock, either the body on the vehicle or that on the trailer can be tipped as required. The tipping gear fitted on the Laffiy vehicle presents a somewhat unusual appearance. Behind the driver's seat is fixed what might be termed a double winch, the arms of which extend above the body and are curved so that there is not too great a distance between their tops and the body when the latter is at its highest position. The wire ropes from the winches are carried over a pair of pulleys at the centre of the arms, and then over another pair at the top, and are connected to the body through the medium of two stout brackets protruding vertically from its base. The winches are driven from the gearbox through the medium of a set of spur and a set of worm gears. This type of gear can be designed to tip to almost any angle, according to the length of the body.

One of the simplest forms of hydraulic tipping gear is incorporated in the Sentinel tipping wagon. The ram is positioned just in front of the rear axle and is arranged to swivel. Water under pressure is utilized as the lifting medium, pressure being obtained by an injector pump similar to that em

ployed for the water feed of the boiler. This-is an aecessible. arrangement, which is proving most efficient.

Carrosserrie Latymer, Ltd., have fitted a very use and simple type of three-way tipping gear to a G.V. electric vehicle. This gear is of the simple, single-screw type, the screw being positioned amidships, and the base being protected by a leather cover in order to prevent the entry of dirt and water. The gear is arranged to be operated eitherby hand or by motor power, a separate motor being positioned under the driver's seat for the purpose, and driving through a long shaft and bevel gearing.

Tho short driving shafts to the worm-driven nut are articulated to allow for the necessary movement of the screw. The pivoting of the body to the chassis is extremely simple, the body pivoting sideways on detachable pins, and on a cross-bar when tipping to tho rear.

In the Tanker wagon a very simple tipping gear of the vertical screw type is embodied, and is arranged to be operated either by hand or by engine power. For the latter purpose a special friction clutch, with grooves cut on its periphery, meshes with similar grooves cut on the crankshaft. From this clutch a roller chain takes the drive to a countershaft, where it is conducted along the frame channel through the medium of a long roller chain to spur gears operating the cross-shaft. The latter carries a bevel pinion meshing with bevel teeth cut on the base of the vertical screw.

The Waytip vehicle of the W. and G. stand was one of the novelties of the Show. It is a very interesting development of the use of the hydraulic rain. The single ram is carried on a framework running on four rollers so that it can be pushed bodily along channel steel girders, which are supported horizontally above the frame proper.

The body is made in two separate qompartments, which, by means of hand-operated clips, can be held down all round or at one side only. Under each compartment the channel steel runners for the tipping gear rollers are hollowed out so that the rollers drop slightly into the hollows and thus keep the ram in the correct position. The enfarged base of the hydraulic cylinder contains the oil pump, which is hand-operated, and attached to the base is a dial, the needle of which indicates the weight of the load in either compartment.

While the weighing operation is being performed, the clips holding the body down are all disconnected and the body is lifted until it just clears the frame.

An interesting twin-screw tipping gear, manufactured by the Eagle Engineering Co., Ltd., is utilized by the Daimler Co. The drive is taken from an extension of the layshaft, this being supported in a suitable bracket bolted to the gearbox

easing. At the end of the shaft is carried the male member of a Ferodo-faced cone clutch, by which the gear can be thrown in or out of action as required. The drive is taken by way of an enclosed chain to a countershaft, at the end of which ride freely two bevel pinions meshing with two crown wheels on the crossshaft between the two tipping screws. Between the two bevel pinions is a double dog clutch, keyed to the countershaft, on which it can be slid into engagement with either of the two bevel pinions, so that the twin screws can be rotated in either direction

according to which bevel pinion is clutched to the countershaft. There is an automatic arrangement by which the dog clutch is thrown out of engagement when the limit of travel in either direction is reached.

A single ram, hydraulic tipping gear, positioned vertically behind the driver's cab, is employed by the Thornyeroft Co. The rant carries at its top a T piece, at the ends of which are pulleys. On each side a wire rope is fitted, attached at one 1-!riii to the frame of the vehicle, and at the other to the bottom of the body.

The coil pump is positioned at the near side of the vehicle, and is driven direct from the flywheel by -means of a friction wheel, which is thrown into contact with the flywheel by means of a lever peeltioned in the cab.

A somewhat similar design of tipping gear is the Wood hydraulic hoist, which war to be seen fitted on a Hallforcl tipping wagon.

One of the A.F.C. exhibits was provided with the A.F.C. double-telescopic ram tipping gear, the oil pump for which is driven by means of a spur gear, this gear being arranged to slide. on its shaft so that it can be put in and out of mesh with a pinion on the layshaft. It is interesting to note that the old form of plunger pump .previously utilized has now been replaced by a gear pump of Albany make.

Another improvement is that when the limit of travel has been attained, the oil-release valve comes into operation and the surplus oil is returned to the reservoir. Formerly this oil was wasted.

The tipping gear fitted to the Newton electric vehicle is very similar to that used on the Orwell. It is of the horizontal screw type, with a body which runs back before tipping. The screw is protected by a easing, but this only covers its top. It is operatedby a separate electric motor carried at the near side of the chassis, not far in front of the back axle, the connection between the motor and the screw being by roller chain. Rollers fitted at the extreme ends of the frame run in the channel steel girders which form the frame of the body. Two small rollers are also carried on a cross-member on the body, and as the latter is pushed back the rollers run up two inclined planes and give the primary lift.

A very npvel form of tipping gear is incorporated in the Autocar chassis. The drive for this is taken from the primary pinion of the gearbox. In one form the drive includes one sliding pinion, which can be moved into mesh with the primary gear and can be operated from the driver's seat, whilst in the larger model the addition of another pinion enables the tipping mechanism to be reversed. From this gearing the drive is taken by a short cardan shaft to a worm and worm wheel, and thence through a spurreducing gear to two arms, one at each side of the chassis. These arms are connected by stout links to the bottom of the body, so that, as the arma revolve, the body rises and falls.

In the smaller model, in order to tip the load the body must rise to its full height before it returns, i but n the reversing type the body can be raised to any height up to the maximum, and then, by bringing another pinion into gear, it returns.

The main point about this gear is that all the operations are practically automatic and can be controlled from the driver's seat. The total time taken to tip the load and to return the body to its ordinary positionis between 20 and 25 seconds. The angle of lift is 43 degrees.

On the Foden steam wagon the pressure for operating the hydraulic ram is obtained by cutting off the water supply to the boiler from the pump and utilizlig the latter for supplying water under pressure to the barrel of the ram. The latter is fixed vertically just in front of the rear axle. The barrel does not ko,vivej, hut there is a sliding joint at the top of the ram to allow for the movement of the boy.

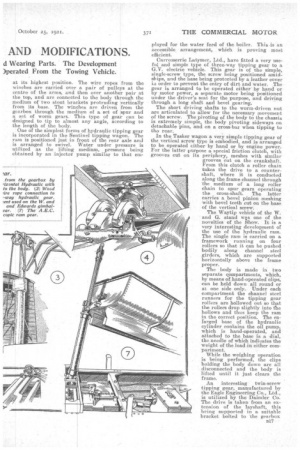

An hydraulle ram, positioned amidships and arranged to swivel, is utilized on the Albion tipping wagon. The pump for this gear is the Hele-Shaw, driven by means of a sprocket carried on the, clutch shaft; this sprocket is provided with dog teeth, so that it can be slid into or out of engagement with other dog teeth secured to the clutch shaft. One of the neatest three-way hydraulic tipping gears is that manufactured by B rem i low and Edwards, Ltd. It is used on various makes of chassis, including the Leyland, K.arrier, COW er Car, and Vulcan, and, as already mentioned, a single-ram type of the same gear is used on the F.W.D. vehicle. The two rams are pivoted on a cross-member which is itself pivoted at its ends. The rams are hall ended, these ends fitting into ball cups carried on the body. The pressure is supplied by a plunger pump, which is driven by a friction wheel from the flywheel. The oil supply to the two rams is interconnected so that they act on a kind of differential principle and one can lift more than the other.

No article on tipping gears would be complete without mention of the well-known Star twin-screw tipping gear.

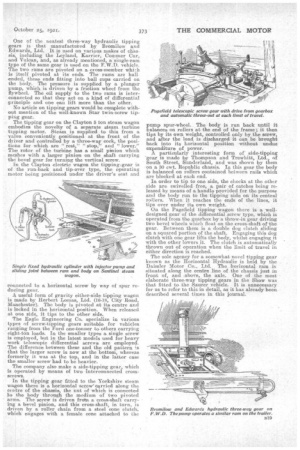

The tipping gear on the Clayton 5 ton steam wagon embodies the novelty of a separate steam turbine tipping motor. Steam is supplied to this from a valve conveniently positioned at the front of the driver and controlled by a three-way cock, the positions for which are " rest," " stop," and " lower." The rotor of the turbine has a small pinion which meshes with a, larger pinion on the shaft carrying the bevel gear for turning the vertical screw.

In the Clayton electric wagon the tipping,gcar is of the run-back and tip-over type, the operating motor being positioned under the driver's seat and connected to a horizontal screW by way of spur reducing gear.

A useful form of gravity either-side tipping wagon is made by Harbert Lomas, Ltd. (16-18, City Road, Manchester). The body is pivoted at its centre and is locked in the horizontal position. When released at one side, it tips to the other side.

The Eagle Engineering Co. specialize in various types of screw-tipping gears suitable for vehicles ranging from the Ford one-tonner to. others carrying eight-ton loads. In the smaller types a single screw is employed, but in the latest models used for heavy work telescopic differential screws are employed. The difference between these and the old pattern is that the larger screw is now at the bottom, whereas formerly it was at the top, and in the latter case the smaller screw had to be heavier.

The company also inako a side-tipping gear, which is operated by means of two interconnected crossscrews.

In the tipping gear fitted to the Yorkshire steam wagon there is a horizontal screw' carried along the centre of the chassis, the nut of which is connected 'o the body through the medium of two pivoted arms. The screw is driven from a cross-shaft carrying a bevel pinion, and this cross-shaft, in turn, is driven by a roller chain from a steel cone clutch; which engages with a, female cone attached to the pump spur-wheel. The body is run back until it balances on rollers at the end of the frame,. it then tips by its own weight, controlled only by the screw, and after the load is discharged it can be brought back into its horizontal position without Undue expenditure of power. A particularly interesting form of side-tipping gear is made by Thompson and Trewhitt, Ltd., of South Street, Sunderland, and was shown by them on a 30 cwt. Republic chassis. In this gear the body is balanced on rollers contained between rails which are blocked at each end.

In. order to tip to one side, the chocks at the other side are swivelled free, a pair of catches being released by means of a handle provided for the purpose and the body run to the tipping side on its central rollers. When it reaches the ends of the lines, it tips over under its own weight.

On the Pagefield tipping wagon there is a welldesigned gear of the differential screw type, which is operated from the gearbox by a throw-in gear driving two bevel wheels Which float on the cross-shaft of the gear. Between them is a double dog clutch sliding on a squared portion of the shaft. Engaging this dog clutch with one gear lifts the body, whilst engaging it with the other lowers it. The clutch is automatically thrown out of operation when the limit of travel in either direction is reached.

The sole agency for a somewhat novel tipping gear known as the Horizontal Hydraulic is held by the Daimler Motor Co., Ltd. The horizontal ram is situated along the centre line of the chassis just in front of, and .above, the axle. One of the most elaborate three-way tipping gears in the Show was that fitted to the Saurer vehicle. It is unnecessary for us to refer to this in detail, as it has already been described several times in this journal.