Failing the annual test wastes time and

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

money— iham provides some practical advice to help ensure that your

trucks pass first time.

s examinations go, the annual CV test is not hard. The standards set for a pass are well within the reach of any adequately maintained truck so there is really no excuse for failure. Maintenance levels and pass rates ave improved in recent years but thousands of trucks still fail at the first attempt, often due to nothing more than a lack of atteption to detail. This is a terrible state of affairs that reflects badly on the industry as a whole.

To find out where operators are going wrong CM visited the Vehicle inspectorate testing station in Mitcham, South London. It's common knowledge that brakes are a prime source of test failures, but station supervisor Lee Williams told CM: 'Here in Mitcham probably the greatest number of failures I see are caused by incorrect headlight adjustment. Foundation brake defects certainly continue to give plenty of problems, but it seems to be the lights which are the biggest weak point. This is a shame because bad alignment is so easy to put right."

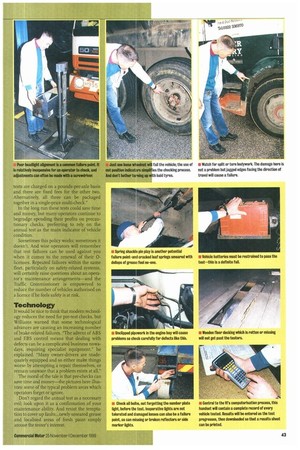

Many other test failures are caused by equally obvious defects, including broken or missing bulbs; loose wheel nuts; cracked or missing light lenses or reflectors; damaged screens; ineffective switchgcar; or split or jagged bodywork.

"From what I see on a daily basis a great many of the common faults could be rectified by the operator prior to the test," Williams remarked. 'A few minutes spent checking the vehicle before it arrives with us would make all the difference—I can't understand why operators don't make a bigger effort."

False economy

It appears that most problems are experienced by owner-drivers who might feel they can't afford to spend time preparing their vehicles when they could be earning a living. But this becomes a false economy when you consider the time taken by having to present vehicles for one or more re-tests.

Station manager Keith Kiverstein was keen to point out that the VI offers an operatorfriendly service. "We make a greater effort to provide additional information about the reasons for failure, and try to ensure that our advisory notes are more comprehensive too," he said.

"Operators tell us they need more feedback about their vehicles, and the re-designed result forms we use help in this respect. The new computer system, scheduled to go live next April, will be really helpful as well. It will speed up turn-around times and increase efficiency for us and the customer."

Another useful service from the VI is the voluntary test programme. Williams explained: "Operators can come here to have separate brake, headlight and exhaust smoke checks done whenever they like. The brake tests are charged on a pounds-per-axle basis and there are fixed fees for the other two. Alternatively, all three can be packaged together in a single-price multi-check."

In the long run these tests could save time and money, but many operators continue to begrudge spending their profits on precautionary checks, preferring to rely on the annual test as the main indicator of vehicle condition.

Sometimes this policy works; sometimes it doesn't. And wise operators will remember that test failures can be used against you when it comes to the renewal of their 0licenses. Repeated failures within the same fleet, particularly on safety-related systems, will certainly raise questions about an operator's maintenance arrangements—and the Traffic Commissioner is empowered to reduce the number of vehicles authorised on a licence if he feels safety is at risk.

Technology

It would be nice to think that modem technology reduces the need for pre-test checks, but Williams warned that some technological advances are causing an increasing number of brake-related failures. The advent of A B S and EBS control means that dealing with defects can be a complicated business nowadays, requiring specialist equipment." he explained_ "Many owner-drivers are inadequately equipped and so either make things worse by attempting a repair themselves, or remain unaware that a problem exists at all."

The moral of the tale is that pre-checks can save time and money—the pictures here illustrate some of the typical problem areas which operators forget or ignore.

Don't regard the annual test as a necessary evil; look upon it as a confirmation of your maintenance ability. And resist the temptation to cover up faults. newly smeared grease and localised areas of fresh paint simply arouse the tester's interest.