adding Performance am Easy Maintenance

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

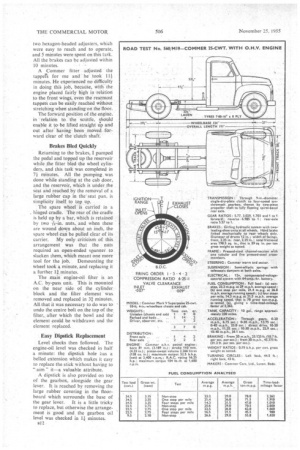

Latest Commer Superpoise 25-cwt. Chassis has a New O.H.V. Engine and Redesigned Cab Good Acceleration and High Top Speed without 'Excessive Fuel Conswnption By John F. Moon,

A.M.I.R.T.E.

.,. „ ,

B,)( using a n-jitre overhead-valve .,ngirierin. the latest: series of Commer.Superpoise 15-cwt. and .11-ton chassis,. the designers .have produced .a . vehicle Which is exceptional in speed,acceleration, and bill

climbing ability.

The transformation of this already popular range of models does not . end there, however. A new threeman cab and front end are now used —the former giving much greater comfort and the latter producing a pleasing modern styling which will blend with. most types of bodywork.

The new range, which was announced at the opening of the "Scottish Motor Show (The Commerrial Motor, November 11), consists of four normal-control models. Three of these have 9-ft. 4-in, wheelbases, two of them being rated for a 15-cwt. payload; the fourth version, a 25-cwt. with a 10-ft. 4-in, wheelbase, was offered to me for test.

This chassis is suitable for use as a lorry (for which purpose it is supplied in chassis and cab form) or as a van with an individually built body. The standard 1f-ton van, as built by Commer, has a 9-ft. 4-in. wheelbase.

The performance during the tests showed this new vehicle to be well in the front rank of its class. Drivers will delight in putting it through its paces and will obviously regret that the maximum speed of over 60 m.p.h. will not, for legal reasons, be usable in this conntry.

This is a driver's vehicle: the cab comfort is of a high order and the visibility--in all directions encourages drivers to make use of the full 'manoeuvrability and liveliness which are .features of the model.

These' Points, combined with good ,brakes accurate steering, add greatly to the value of the chassis, but it will be the overseas operator who will obtain most benefit, principally because its speed capabilities cannot be exploited in this country.

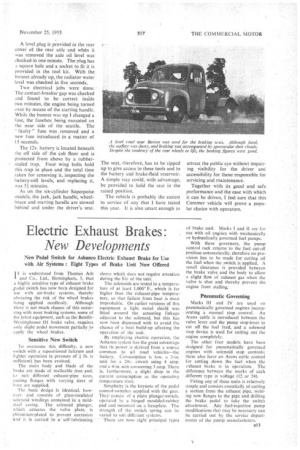

High performance has not been obtained at the expense of fuel consumption. A 25-cwt. load can be carried at an average consumption figure of at least 23 m.p.g. The Superpoise, therefore, gives the best of both worlds.

The test vehicle, complete with standard cab and oil,. fuel and water, turned the scale at 1 ton 9 cwt.A :test load of iron weights mounted on

• a timber platform, equivalent to a 25-c-wt. payload with a 9!-cWt. body, was added. It is unlikely that• the normal body weight would be as high

as 9} cwt., but the 2 cwt. overload on the gross weight could hardly have affected the performance.

Accompanied by a Commer representative, I went out to Barton for acceleration and braking tests. At speeds up to 607n.p.11. the vehicle was remarkably steady,, safe and light to handle. The road chosen for the tests at Barton was reasonably level and straight, and the surface was hard but dusty.

Emergency stops from 30 m.p.h. produced pronounced skidding with all wheels locked, and the rear wheels showed a tendency towards bouncing, which added to the stopping distance. Several tests were made in each direction with the same result, but the average figure of 45.375 ft. from 30 m.p.h. is good.

Skidding also accompanied fierce braking from 20 m.p.h., although not to such a great extent, and during the.;e. -tests a maximum deceleration figure of 82 per cent, was recorded on the Tapley meter. The meter was also used for the hand-brake tests and an average reading of 38.5 per 'cent, was obtained when making emergency stops.on the hand brake alone from 20 mph. No excessive force was required to make the rear wheels lock; showing, the hand brake to be useful in an emergency as well as for parking.

One of the advantages of an over

head-valve engine was shown to the

full during acceleration tests. The works driver used first gear in moving from rest and reached 40 m.p.h. in 25 sec.—an exceptionally good figure. The direct-drive tests were no less vivid, and I was pleased to find that the engine and transmission were reasonably smooth when pulling away from below 10 m.p.h.

Sundon Hill, 0.6 mile long, with an average gradient of 1 in 13 and a maximum gradient of 1 in 5.75, was

the next place of call. Our first attempt at scaling this incline resulted in an affray with a 7-ton truck, which was shedding sacks of potatoes on the roadway, but on the second attempt the Commer sailed up the hill with disdain for its steepness.

The climb was made for the most part in secima gear, this ratio being used when the road speed had fallen to 12 m.p.h. The ambient temperature was 66° F., and at the top of the hill it was found that the water tem perature had risen • by 1 F. to 177° F.

Returning to the steepest section, a stop:start test was made. The band brake' Proved "caPable.of holding the . vehicle on this gradient with four notches in hand, and an easy first

gear start was made.

Curiosity prompted me to try a start in second gear, but it was hardly surprising that this did not quite come off. The first-gear start, however, showed there to be ample power in hand and gradients of up fh 1 in 3.25 should be manageable._ A return circuit of 5.8 miles on the road between Barton and Clophill, a severely, undulating route, was used

for the consumption tests. Laden, part-laden and unladen runs were made to assess performance accurately under varying conditions. Contihuous-running and stopping tests were made under each of these three conditions.

Although the route included a sec lion where road repairs were in progress, most . of the runs were made without involuntary stops, although two halts were necessary during the first test, which was intended to be conducted non-stop, fully laden. The results are stimmarized in an accompanying table.

Having finished the road work, .various maintenance tasks were carried out at the Commer works, the first of these being to adjust the brakes.

A screw-type jack is supplied with the tool kit, and, with 12 cwt. of the total payload removed, it was possible to raise both rear wheels simultaneously by placing the jack under the differential casing. The rear brakes were very easy to adjust, there being one square-headed

adjuster on each backplate. The total time spent on this job was 41 minutes, including jacking up the wheels and letting them down again.

Both front wheels were also jacked up together and here again, adjustmem war,. simple. Each brake has

two hexagon-headed adjusters, which were easy to reach and Co operate, and 5 minutes were spent on this task. All the brakes can be adjusted within 10 minutes.

A Cornmer titter adjusted the tappers for me and he took 111 minutes. He experienced no difficulty in doing this job, because, with the engine placed fairly high in relation to the front wings, even the rearmost tappets can be easily reached without stretching when standings on the floor.

The forward position of the engine, in relation to the scuttle, thciuld enable it to be lifted straight up and out after= having been 1.noired forward clear of the clutch shaft.

Brakes Bled Quickly Returning to the brakes, I pumped the pedal and topped up the reservoir while the fitter bled the wheel cylinders, and this task was completed in 7 minutes. All the pumping was done while standing at the cab door, and the reservoir, which is under, the seat and reached by the removal of a large rubber cap in the' seat pan, is simplicity itself Co top up.

The spare wheel is carried in a hinged cradle. The rear of the cradle is held up by a bar, which is retained by two nuts, and when these are wound down about an inch, the spare wheel can be pulled clear of its

carrier. My only criticism of this arrangement was that the nuts required an open-ended spanner to slacken them, which meant one more tool for the job. Demounting the Wheel took a minute, and replacing it a further 1,1 minutes.

The main engine-oil filter is an A.C. by-pass unit. This is mounted on the near side of the cylinder. block and the filter element was removed and replaced in 3.1 minutes. All that it was necessary to do was to undo the centre bolt on the top of the filter, after which the bowl and the' element could be withdrawn and the element replaced.

Easy Dipstick Replacement

Level checks then followed. The engine-oil level was checked in half a minute: the dipstick hole has a belled extension which makes it easy to replace the stick without having to ". aim " it-a valuable attribute.

A dipstick is also provided on top of the gearbox, alongside the gear. lever. It is reached by removing the large rubber covering in the floorboard which surrounds the base of

the gear lever. It is a little tricky to replace, but otherwise the arrangement is good and the gearbox oil level was checked in 11 minutes.

2 A level plug is provided in the rear cover of the rear axle and when it was removed the axle oil level was checked in one minute. The plug has a square hole and a socket to fit it is provided in the tool kit. With the bonnet already up, the radiator water level was checked M. five seconds.

Two electrical jobs were done. The contact-breaker gap was checked and found to be correct inside two minutes, he engine being turned over by means of the starting handle. While the bonnet was up I changed a fuse, the fusebox being mounted on the near side of the scuttle. The faulty" fuse was .removed and a new fuse introduced in a matter of 15 seconds.

The I2v. battery is located beneath the off side of the cab floor and is protected from above by a rubber . sealed trap. Four .wing bolts hold this trap in place and the total time taken for removing it, inspecting the battery-cell levels, and replacing it, was 5A minutes.

As on the six-cylinder Superpoise models, the jack, jack handle, wheelbrace and starting handle are stowed behind and under the driver's seat. The seat, therefore, has to be tipped up to give access to these tools and to the battery and brake-fluid reservoir. A simple stay could, with advantage, be provided to hold the seat in the raised position.

The vehicle is probably the easiest to service of any that 1 have tested this year. It is also smart enough to attract the public eye without impairing visibility for the driver and accessibility for those responsible tot servicing and maintenance.

Together with its good and safe performance and the ease with which it can be driven, I feel sure that this Commer vehicle will prove a popular choice with operators.