I With the lights disconnected the front panels are removed, the

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

left side of the cab is supported and all mounting brackets and bolts are removed from the chassis, right back to the engine mounting.

The first flitch plate is slid inside the original channelling and secured there using new 10.9mm high-tensile steel bolts.

The process is repeated at the other side of the frame; all bolts are removed, including those holding the steering box, and a new inner sleeve is introduced. Again, larger bolts lock it in place.

With the flitch ends protruding a good 18in (460mm), the new front tow hitch is offered up for new matching holes to be drilled and then everything is bolted in place.

An 80mm very-high-tensile 24-grade steel hitch pin is used. All that's left is to recess the front panel to clear the frontal projection, reposition the air and electrical conduits along the inside of the frame, and then fit the suzie connectors.

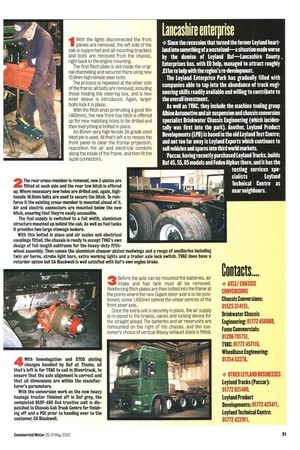

A. The rear cross-member is removed, new Z-plates are

fitted at each side and the rear tow hitch is offered up. Where necessary new holes are drilled and, again, hightensile 10.9mm bolts are used to secure the hitch. To reinforce it the existing cross-member is mounted ahead of it. Air and electric connectors are mounted below the new hitch, ensuring that they're easily accessible.

The fuel supply is switched to a full width, aluminium structure mounted up behind the cab. As well as fuel tanks it provides two large stowage lockers.

With this bolted in place and air suzies and electrical couplings fitted, the chassis is ready to accept TVAC's own design of full-length subframe for the heavy-duty fifthwheel assembly. Then comes the aluminium chequer plated mudwings and a range of ancillaries including twin air horns, strobe light bars, extra working lights and a trailer axle lock switch. TVAC does have a retarder option but CA Blackwell is well satisfied with Oaf's own engine brake.

3Before the axle can be mounted the batteries, air intake and fuel tank must all be removed. Reinforcing flitch plates are then bolted into the frame at the points where the new Gigant steer axle is to be positioned, some 1,450mm behind the wheel centres of the front steer axle.

Once the extra unit is securely in place, the air supply is re-piped to the brakes, valves and locking device for the straight ahead. The batteries and air reservoirs are remounted on the right of the chassis, and the customer's choice of vertical Wasey exhaust stack is fitted.

A With homologation and MO plating 'MT changes handled by Daf at Thame, all that's left is for TVAC to call in Steertrack, to ensure that the axle alignment is correct and that all dimensions are within the manufacturer's parameters.

With the conversion work on the new heavy haulage tractor finished off in Oaf grey, the completed 95XF-480 8x4 tractive unit is dispatched to Chassis Cab Truck Centre for finishing off and a POI prior to handing over to the customer, CA Blackwell.