to Gt 4:10 1CS

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

Water injection revived

WATER INJECTION was being played around with the best part of half-century before the pollution scare. And it is reliably reported that the late Freddie Dixon, the Riley tuning and racing maestro, used water injection to good effect with a system that he evolved himself,and kept secret until his death.

Water has a very high latent heat of vaporization and extracting heat from the cylinders by water injection during the early part of combustion can reduce the peak pressure and increase the pressure lower down the stroke in a more usable form. At least that was the idea.

But water injection has recently been successfully developed experimentally to combat pollution, notably the emission of oxides of nitrogen, and the experiments indicate that there could well be other properties of the system that could aid combustion in a petrol engine in different ways.

It has even been suggested that a cloud physicist should be called in to explore humidification as it could be applied to aspirated air and its effect on fuel charge regulation in the combustion chambers.

Experiments in Wisconsin University have proved that water sprayed continuously on to the inlet valve of a laboratory petrol engine can give worthwhile improvements in fuel consumption and bmep as well as a big reduction of Nox. While the gains are attributable to reduced flame temperatures, they are said to result from dilution rather than vaporization of the water.

Lower octane fuel The United States Army Fuels and Lubricants Research Laboratory has used water injection to cool a spark ignition engine by direct injection into the cylinder and later condensation of the steam in the exhaust system by means of a heat exchanger. In addition to cooling the engine adquately, the system enables a fuel of lower octane rating to be employed and the emission of oxides of nitrogen to be reduced.

It is reported that leading engine manufacturers in the UK are experimenting with diesels equipped with direct • water injection. The author experimented with water injection in a rather haphazard way over 30 years ago as an engineering student, but could not cope with the problem of metering water into the intake in the right proportions and in the most productive way.

The system gave smoother running on a lower octane fuel. But obviously the limited advantages of water injection as shown to be obtainable at that time would not justify the expense of employing power-operated injectors in each cylinder or intake unless it could overcome emission problems. And there are many variables such as spray pattern, temperature, timing and so on, which could only be evaluated by extensive research and development work.

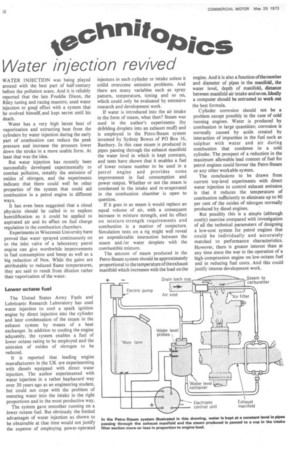

If water is introduced into the air intake in the form of steam, what then? Steam was used in the author's experiments (by dribbling droplets into an exhaust muff) and is employed in the Petro-Steam system invented by Sydney Bowes of PO Box 16, Banbury. In this case steam is produced in pipes passing through the exhaust manifold the water level in which is kept constant, and tests have shown that it enables a fuel of lower octane number to be used in a petrol engine and provides some improvement in fuel consumption and power output. Whether or not the steam is condensed in the intake and re-evaporated in the combustion chamber is open to question.

If it goes in as steam it would replace an equal volume of air, with a consequent increase in mixture strength, and its effect on mixture-Strength requirements and combustion is a mattter of conjecture. Simulation tests on a rig might well reveal an unpredictable interaction between the steam and /or water droplets with the combustible mixture.

The amount of steam produced in the Petro-Steam system should be approximately proportional to the temperature of the exhaust manifold which increases with the load on the engine. And it is also a function ofthenumber and diameter of pipes in the manifold, the water level, depth of manifold, distance between manifold air intake and soon.Ideally a computer should be entrusted to work out the best formula.

Cylinder corrosion should not be a problem except possibly in the case of cold running engines. Water is produced by combustion in large quantities; corrosion is normally caused by acids created by interaction of impurities in the fuel such as sulphur with water and air during combustion that condense in a cold cylinder. The prospect of a reduction in the maximum allowable lead content of fuel for petrol engines could favour the Petro-Steam or any other workable system.

The conclusions to be drawn from current top-level experiments with direct water injection to control exhaust emission is that it reduces the temperature of combustion sufficiently to eliminate up to 90 per cent of the oxides of nitrogen normally produced by diesel engines.

But possibly this is a simple (although costly) exercise compared with investigation of all the technical parameters of designing a low-cost system for petrol engines that could be individually and accurately matched to performance characteristics. However, there is greater interest than at any time since the war in the operation of a high-compression engine on low-octane fuel and in reducing fuel costs. And this could justify intense development work.