Up goes profit share for freight group...

Page 37

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

IT IS widely believed that Christian Salvesen (road and freight transport, cold storage, fishing, house-building and shipping) one of the largest privately owned companies in the UK, will be coming on to the stockmarket.

Latest results for the firm have been encouraging, and show profits for the group have advanced significantly.

They amounted to £6.3 million for the 12 months ended September 1976, and these earnings represented a rise of 34 per cent compared to the previous year.

Total sales were also higher and reached £89.5 million.

The house-building side is believed to account for 30 per cent. of the total turnover, cold storage represents 25 per cent, while the shipping and fishing account for 27 per cent.

The group has been expanding rapidly into allied fields, particularly into off-shore drilling through Salvesen Offshore Holding Co.

Over the past few years. the group has been growing rapidly by internal expansion, as well as by acquisitions. Turnover reached £89.5 million in 1976 compared to £28.7 million in 1971, as can

Profits

Total profits have fluctuated considerably, and the group has suffered from narrowing margins in 1974, when earnings dropped to £1.7m (see Table 2).

At the trading level, Christian Salvesen has maintained a reasonable level of profit margins. In fact, trading margins averaged 11 per cent between 1971 and 1976, but as a result' of sharply rising interest charges, pretax margins dropped substantially during 1974-75 (see graph 2).

During those years, the group was highly geared, partly because of its expansion into offshore drilling and partly because of escalating rates.

The return on capital of the group has fluctuated, though over the past few years it has averaged about 12 per cent; this can be considered satisfactory because of the capital intensive nature of the group's activities.

Outlook

The directors are cautious about the outlook for profits in the current year, and have warned that they could be lower: for one thing, higher losses are expected from the associated company (Salvesen Offshore Holding), while higher interest charges are being incurred at present.

Nevertheless, the board is hopeful of long-term growth and the group's interests in transport and cold storage are likely to show increasing contributions to overall profits.

It is also encouraging that the board has decided to raise the dividend, which was fixed at eight pence per share for 1976 compared to 7.3 pence in the previous year. BREAKDOWN recovery has never been a major problem, accident recovery is something quite different. It demands a specialist skill and technique and sophisticated recovery equipment. The problems of accident recovery in the USA are greater than in any of the other developed countries — simply because of the size of the country and the vehicle population.

It was an American Dale Carnegie who said: "There is an answer to every problem so stop worrying and start living.' The trick is to find the answer. Recently I went to the States to discover how it had answered its accident recovery problem.

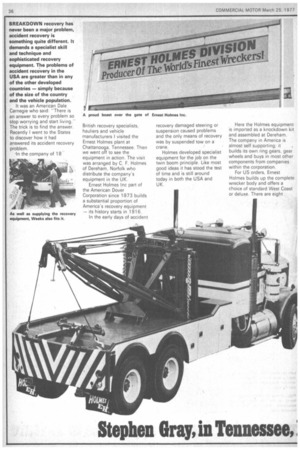

-In the company of 18 British recovery specialists, hauliers and vehicle manufacturers I visited the Ernest Holmes plant at Chattanooga, Tennessee. Then we went off to see the equipment in action. The visit was arranged by C. F. Holmes of Dereham, Norfolk who distribute the company's equipment in the UK.

Ernest Holmes Inc part of the American Dover

Corporation since 1973, builds a substantial proportion of America's recovery equipment — its history starts in 1916.

In the early days of accident recovery damaged steering or suspension caused problems and the only means of recovery was by suspended tow on a crane.

Holmes developed specialist equipment for the job on the twin boom principle. Like most good ideas it has stood the test of time and is still around today in both the USA and UK. Here the Holmes equipment is imported as a knockdown kit and assembled at Dereham. The company in America is almost self supporting; it builds its own ring gears, gear wheels and buys in most other components from companies within the corporation.

For US orders, Ernest Holmes builds up the complete wrecker body and offers a choice of standard West Coast or deluxe. There are eight models of wrecker from which to choose in both the US and UK At the lower end of the scale there is the 220 which has a rating capacity of 4.1 tonnes (4 tons) and is most suited to recover cars or very light trucks and vans. This smallest model is electrically !operated to eliminate the need for a pto.

At the top of the range is the 850 which is Holmes' most powerful wrecker with a rating of 41 tonnes (40 tons). Included in the specification are rear jacks to aid load distribution. All pilot wrecker models are fitted to a test rig where they are subjected to different loads.

These test results are used to work out the ratings for the wrecker's performance. It has to be remembered, of course, that the rating is only applicable to the recovery equipment, not to the finished wrecker vehicle.

Matched gears For fitting to the larger wrecker equipment, Holmes cuts and heat treats all its own gears and matches them on a special fixture to minimise gear wear and to allow the gears to run smoothly and quietly. The gears are straight cut. When a set is completed, it is fitted into the power unit which incorporates self activated internal brakes able to apply full holding power when the control is returned to neutral. Steel jaw clutches are fitted to give positive take up.

By comparing all the heaviesin Europe with those in America, it is easy to see why Holmes says the 750 is the most popular model. It has a capacity of 25.4 tonnes (25 tons) but can be used for

light vehicles as well. Again it can be specified with West Coast or deluxe bodywork. An angled tailgate to the bodies has been designed to give greater articulation when towing large vehicles.

Operator training

The Ernest Holmes company feels very strongly about operator training, and in fact is hoping to start its own training school. A mail shot to known users has brought an overwhelming response — even though Holmes will be making a charge for the school.

Ifs essential, says Holmes, to match the equipment to be used to the job in hand. All cables and gear should be maintained in good order and replaced if overloaded. When recovering a vehicle, care must be taken to stabilise the wrecker properly during the operation and when raising the booms. To extend cable life, they should be wound carefully on to the drum and under no circumstances should they be overloaded. Although they might not break on the first job, they almost certainly would on the next.

' By using snatch blocks correctly a greater mechanical advantage can be gained. However, merely using snatch blocks to alter the cables' direction will not reduce cable tension.

When the blocks are used to multiply the winch power and reduce tension, the cable angles must be kept low. A practice which Ernest Holmes abhors is the use of cable clips. These can reduce the efficiency of the cable to 80 per cent or less, even when properly fitted. In addition, they can damage the cable beyond repair.

To help operators work out what rated wrecker they need to buy, Holmes categorises them as follows: for light vehicles a rating of 4 to 8 tons, for medium vehicles 10 to 16 tons and heavy vehicles 25 to 40 tons. It does stress however the importance of correct usage of the equipment regardless of type or size.

Under no circumstances should the front of the vehicle be tied down or an extra heavy ballasted front end be used, as this can lead to a bent vehicle chassis and possible danger to the operator.

To see the equipment at work with a larger wrecker operator I visited Stepps of Tampa, Florida, who uses only Holmes wreckers. Stepps belongs to an organisation of recovery operators which banded together for mutual assistance. Having set their parameters, the association's members decided what they would like to see happen in the recovery business and set their sights at achieving it.

Among their successes is an increase in rates for police work and measures to stamp out pirates by assigning areas to individual operators. The .association has helped, it believes, to give the recovery business a better name and to improve professional standards.

Increased rates

In the case of the increased police rate they are now able to earn $22 per call out instead of $17. All the recovery vehicle drivers working for Stepps are employed on a freelance basis. They are only paid if they get a call out and then they draw a third of the total cost. As the minimum charge is $50 for a heavy recovery they can earn themselves quite a lot if business is brisk.

The vehicle recovery specialists on the trip were so impressed by the American organisation that they intend making the same moves in Britain. CM has been invited to assist in this venture. As a first step we are extending facilities at the Vehicle Recovery Conference at Wembley on the afternoon of Friday, May 6 for an inaugural meeting.