HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

501.—Curing a Slipping Fan Belt.

A_ slipping -fan belt is a trouble which can cause considerable annoyance. 1t, seldom occurs with the link-type belt, but fairly often-,-with the fiat belt. -Tightening the belt does not always effect a cure and, as is well known, a tight belt will quickly wear the bearings, apart from the possib lity of pulling the belt fasteners through.

• A simple but effective method which was recently tried was to secure several rubber bands, such as can be bOught at any stationers, and to stretch these round-the pulley side by side. This has the .effect of increasing the coefficient of friction between the pulley and the belt, and the bands will wear a long time, providing that grease and oil are prevented from reaching the rubber.

502.—Some Useful Notes on the Swiss Berna.

' Several interesting improvements to the four-ton Swiss Berna are contained in a letter sent to us recently by a user of one of these vehicles.

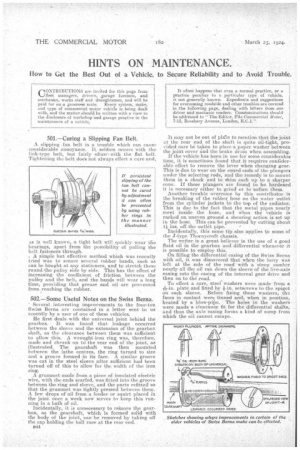

He first deals-with the universal joint behind the gearbox. It was found that leakage occurred between the sleeve and the extension of the gearbox shaft, as the clearance between them was sufficient to allow this, A wrought-iron ring was, therefore, made and shrunk on td-the rear end of the joint, as illustrated. The gearshaft was then mounted between the lathe centres, the ring turned to size and a groove formed in its face. A similar groove was cut in the steel sleeve after sufficient had been turned off of this to allow for the width of the iron ring.

A grommet made from a piece ef insulated electric wire, with the ends scarfed, was fitted into the groove between the ring and sleeve, and the parts refitted so that the grummet was tightly pressed between them. A few drops of oil from a feed-er or squirt placed in the joint once a week now series tokeep this running in a bath of oil.

Incidentally, it is unnecessary to remove the gearbox, as the gearshaft, which is formed solid with the body of the joint, can be removed by taking off the cap holding the ball race at the rear end.

B44

It may not be out of pla72.e to mention that the joint at the rear end of the shaft is quite oil-tight, provided care be taken to place-a paper washer between the joint cover and the brake drum when assembling:

If the vehicle has been in use for some considerable time, it is sornetiines found that it requires considerable effort to remove the lever when changing gear. This is-due to wear on the coned ends of the plungers under the selecting rods, and the remedy is to mount them in a chuck and to skim each up to a sharper cone.. If -these plungers are found to be hardened it is necessary either to grind or to-soften them.

Another troubleovercome by this contributor -is the, breaking of the rubber hose on the water outlet from the cylinder jackets ito the top of the radiator. This is due to the fact that the metal pipes nearly meet inside the hose, and When the vehicle is racked on uneven ground a shearing action -is set up in the hose. This can be prevented by cutting about 14 ins, off the outlet pipe. .

Incidentally, this same tip also applies to some of the J-type Thornycroft chassis.

The writer is a great believer in the use of a good fluid oil in the gearbox and differential whenever it is possible to employ this.

On filling the differential casing of the Swiss Berna with oil, it was discovered that when the lorry was left at the side of the road with a steep eamber nearly all the Oil ran down the sleeve of the live-axle casing into the casing of the internal gear drive and then on to the road.

To effect a cure,' steel washers were made from a re' -in. plate and fixed by. kin. setscrews to the spigot on each sleeve. Before fixing these washers, the faces in contact were tinned and, when in position, heated' by a blow-pipe. The holes in the washers were made a clearance fit for the differential shuts, and thus the axle easing forms a kind of sump from which the oil cannot escape.