Commercial Body-building in Quantities.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

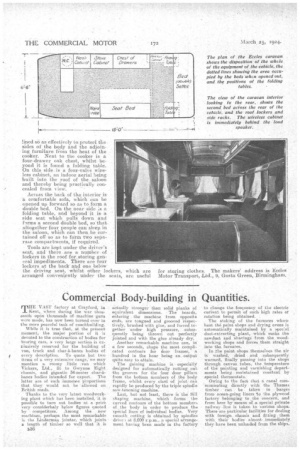

T" ' A.ST factory at Crayford, in Kent, where_ during the war thou0,13.116 11.1p5n thousands of machine guns were ina•de, has now been turned over to the more peaceful task of coachbuilding. While it is true that, at the present moment,the major portion of it is devoted to the construction Of bodies for touring cars, A very large section is exiusively reserved for the building of van, truck and char-ti-bancs bodies of every description. To quote but two items very extensive range,' we may mention a roomy little va•n which 'Vickers, Ltd., fit to Gwynne Eight chassis, and gigantic 34-seater char-bbanes bodies intended for export. The latter are of such _immense. proportions that they would not. be allowed on British roads. Thanks to the very latest woodworking plant which has been installed, it is possible to turn out bodies ..at. a price very coesiderbaly below figures quoted by • competitors. Among the new machines. perhaps the most remarkable is the Linderman jointer, which joints a length of timber so well that it is

L36

actually -stronger than solid planks of equivalent dimensions. The boards, entering the machine from opposite ends, are tongued and grooved respectively, brushed with glue, and forced together under high pressure, subse9nentiy being thrown out perfectly 3ointed and with the glue already dry. Another remarkable machine can, in a few seconds, shape the most complicated contours for door frames, a hundred in the hour being an outPut quite easy to attain. The gaining Machine is especially designed for automatically cutting out the grooves for the four door pillars from the bottom members of the body frame, whilst every clas1 of joint can rapidly be produced by the triple spindle saw-tenoning machine. Last, but not least, there is the Sill shaping machine, which forms the curved contours of the bottom members of the body in order t-o produce the special lines of individual bodies. Very smooth cutting is obtained by spit-idles drive at 8,090 r.p.m., a special arrangement having been made in the faCtory to change the frequency of the electric current to permit of such high rates or rotation being obtained. The stoking of the furnaces which heat the paint shops and drying ovens is automatically maintained by a specal dust-extracting plant, which sucks the sawdust and shavings from the woodworking shops and forces them straight into the furnaces. In ,the paint shops themselves t•he air is washed, dried and subsequently warmed, finally passing into the shops through canvas tubes, the temperature of the painting and varnishing departments being maintained constant by special thermostats. Owing to the fact that. a canal com"municating directly with the Thames. timber can be taken in barges fromocean-going liners to the plywood factory belonging to the concern, and from here by means ti.f a special private railway .line is taken to various shops. There are particular facilities for dealing With foreign. chassis and fitting them with their bodies almostimmediately they have been unloaded from the ships.