Scammell Trunker ha5 ;econd Steering Axle foi 52 tons g.t.w.

Page 66

Page 67

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

ByAJ P WILDING

AMIMechE.,

nNE of _ the anomalies of the latest Construction and Use Regulations is that whilst 32 tons gross is allowed for a four-axle outfit, the outer axle spread of 38 ft. that this entails makes it impracticable and practically impossible to design such a vehicle within a 42 ft. 7.75 in. overall length. So for 32 tons gross a five-axle artic is needed, but there is not much point in having an extra axle to increase from 30 to 32 tons gross when the axle and other parts that have to be fitted take up most of the 2 tons gained.

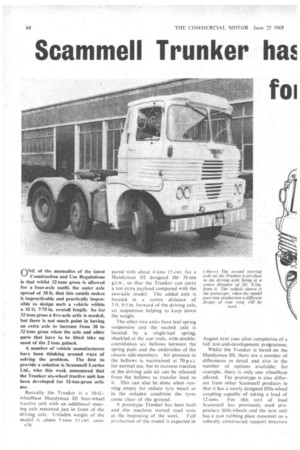

A number of vehicle manufacturers have been thinking around ways of solving the problem. The first to provide a solution is Scammell Lorries Ltd., who this week announced that the Trunker six-wheel tractive unit has been developed for 32-ton-gross artic use.

Basically the Trunker is a 10-ft.wheelbase Handyman Ill four-wheel tractive unit with an additional steering axle mounted just in front of the driving axle. Unladen weight of the model is about 5tons 15 cwt. corn (-34

pared with about 4 tons 15 cwt. for a Handyman Ill designed fen30 ton g.t.w., so that the Trunker can carry a ton extra payload compared with the two-axle model. The added axle is located at a centre distance of 3 ft. 9:5 in. forward of the driving axle, air suspension helping to keep down the weight.

The other two axles have leaf-spring suspension and the second axle is located by a single-leaf spring, shackled at the rear ends, With doubleconvOlution air bellows between the spring pads and the undersides of the chassis side-members. Air pressure in the bellows is Maintained at 70 p.s.i. for normal use, but to increase traction at the driving axle air can be released from the bellows to transfer load to it. This can also be done when running empty (to reduce tyre wear) as in the unladen condition the tyres come clear of the ground.

A prototype Trunker has been built and this machine started mad tests

at the beginning of the week. Full production of the model is expected in August next year after completion of a full test-and-development programme.

Whilst the Trunker is based on the Handyman Ili, there are a number of differences in detail and also in the number of options available; for example, there is only one wheelbase offered. The prototype is also different from other Scammell products in that it has a newly designed fifth-wheel coupling capable of taking a load of 12 tons. For this sort of load Scaturnell has previously used pro prietary tifth-wheels and the new unit has a cast rubbing plate mounted on a robustly constructed support structure which is bolted to 0-5 in. plates welded to the flanges of the frame sidemembers. These plates also provide the added strength needed for 32 tons g.t.w., as there is no other difference in the frame design from the Handyman 111. The cab used on the Trunker is the Michelatti-designed plastics unit as used on the Handyman UI with entry over the wheels. Two engine options are offered --the Leyland Power-Phis 0.680 with a maximum net output of 200 b.h.p. at 2,200 r.p.m. and maximum net torque of 548 lb. ft. at 1,200 r.p.m., and the Gardner 6LX which produces 150 b.h.p. (net) at 1,5(X) r.p.m. and 485 lb. ft. net torque at 1,000 r.p.m. With the 0.680 only, a no-loss" coolant system is employed.

Alternative Ratios With both engines, the power is transmitted through a Scammell sixspeed overdrive gearbox with ratios of 6-55, 4-07, 153, 1-61, 1 and 0-623 to 1 forward, and 8-37 to I reverse. Alternative gear ratios can be supplied to suit particular operating conditions. This gearbox is used also on the Handyman ill and its predecessor the Handyman It—and the same applies to the driving axle, which is the Scammell fully floating spiral-bevel and epicyclic double-reduction unit. Load capacity of the axle is 10 tons, this figure having been increased from 9 tons at the time of the introduction of the Handyman III. Final-drive ratios available are 6-44, 7-13,. 7-78, 8-56 and 9-4 to 1.

The front and second steering axles are identical and have 15-5 in. by 4-25 in. brakes, whilst the driving axle brake size is 15-5 in. by 7 in. All are S-cam operated and the total frictional area is 829 sq. in. The air-pressureoperating system is based on the design produced by Scammell to meet the requirements for emergency and secondary systems under the new regulations did was announced some months ago. Triple-diaphragm chambers are used at the front and driving axles with single-diaphragm units at the second steering axle.

Both actuating diaphragms of the front-axle units are 20 sq. in., the single-diaphragms of the second axle are 9 sq. in. and the triples at the rear are Type 24/30; 24 sq. in. are for service actuation, and the 30 sq. in. are brought into use on application of the handbrake. On service-brake application, the diaphragms at all three axles are actuated together with the service line to the semi-trailer coupling.

The foot-brake valve is a dual unit (-36

and feeds the emergency or secondary braking system at a pressure 25 p.s.i. less than that applied to the service line (and at the same time), the fullbraking pressure being obtained in the emergency side only after the pedal has been moved beyond the point at which full service braking is normally obtained. This means that there is no delay in the application of the emergency system when a sudden failure of the service brake system occurs. But as the emergency brake is applied only to the front axle and to the auxiliary coupling for the semi-trailer brakes it is debatable that sufficient safety and stability will be retained in the event of service-brake failure. A favourable point in this connection, however, is that application of the mechanical handbrake directs air to the secondary side of the driving-axle diaphragms so that two of the three tractive unit axles can be braked in an emergeney.

A hand-reaction valve for separate application of the semi-trailer brakes is not fitted in the cab as standard; but this can be supplied on request, in which case the usual connection to the trailer service coupling is made.

The Trunker has been designed so that with the fifth-wheel mounted 18 in. forward of the driving axle the first and second steering axles carry 3 tons each and the driving axle 10 tons when 11-5 tons is applied to the coupling; releasing air from the second-axle suspension puts 2 tons on the driving axle and 6 cwt. on the front steering axle.

To cater for the load on the steering

axles, power-assisted steering is standard. The steering box is an Adamant cam-and-double-roller type and incorporates valves arranged to feed oil under pressure to a ram which operates on the auxiliary drop arm in the steering linkage to the second axle. Standard tyres on the first and second axles are 9.00-20 (12-ply) and on the driving axle 10.00-20 (16-ply), although other sizes can be supplied.

The space between the first and second axles restricts the size of fuel tank which can be employed, and to get over this difficulty two 25-gal. tanks are used, one on each side of the frame. Both have filler caps and are linked so that they can be filled from one point al the same time.

No Tyre Scrub Whilst at the Scammell factory getting details of the Trunker I was able to make a short run in the prototype, this being coupled to a

Sta mrnell tandem-axle semi-trailer and running at 30 tons g.t.w. There was nothing in the performance of the vehicic to indicate that the tractive unit was not a four:wheeler and it was particularly noticeable on making a tight turn that there was a complete absence of bogie-tyre scrub which one would expect with a conventional sixwheel tractive unit or rigid vehicle.

The driver commented favourably on the lightness of the steering; this was to be expected, as although there was 6 tons over the steering axles the angular movement of the second axle is only about one third that of the front axle because of its being set close to the driving axle.