CAN THE FIRST COST OF ELECTRICS BE LOWERED?

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How, by Reducing Overhead Charges, the Batteryelectric Machine Could Become Competitive with the Petrol-driven Lorry By "Azote " 6 T the outbreak of war, there were not more than 5,000 battery-electric vehicles in this country and,

1 i,

• of that total, only three were private cars, the rest• being goods vehicles. The blame for this paucity of electries is attributed to excessive battery weight, low speed and limited range of operation.

As a matter of fact, these reasons are not the correct explanation. In •normal times there are nearly 140,000 goods vehicles operating in this country, the daily duty of which never exceeds the mileage it is possible to get on a battery charge, Neither is the speed too low, because an electric vehicle accomplishes its daily tasks in the same time as its petrol competitor. Battery weight is a relative matter, and is taken into consideration in the foregoing statement of facts.

Weight reduction would • be most acceptable, but it is not a matter concerned in the 140,000 vehicles under discussion. Should a really light battery be invented, this number would automatically be increased, and would, in all probability, result in a big reduction in the half a million, or so, petrol-driven goods vehicles normally in service.

The real reason why there are only 5,000 electrics, instead of 140,000, is that the cost of the electric van is twice that of its petrol competitor. This is taking pre-war prices of £167 for a petrol-driven van of 10-cwt. pay-load and £325 for an electric van of approximately equal capacity.

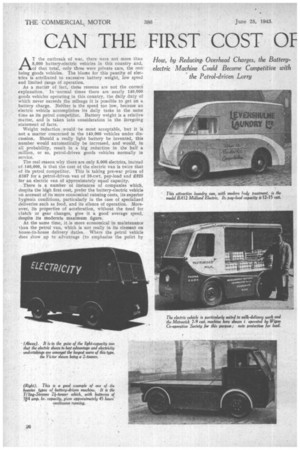

There is a number of instances of companies which, despite the high first cost, prefer the battery-electric vehicle on account of its more economical running costs, its superior hygienic conditions, particularly in the case of specialized deliveries such as food, and its silence of operation. Moreover, its properties of acceleration, without the need for clutch or gear changes, give it a good average speed, despite its moderate maximum figure.

At the same time it is more economical in maintenance than the petrol van, which is not really in its element on house-to-house delivery duties. Where the petrol vehicle does show up to advantage (to emphasize the point by repetition), is in the small initial Outlay involved, which so often outweighs all other considerations.

-Reducing the cost of an electric vehicle is not an impsSible matter, as analysis of the reasons for its relatively high cost Will show how reductions can be made so as to make the battery-electric strictly competitive with the petrol vehicle. Although there are electrics running with pay-load capacities from 2 to 5 tons, by far the greater percentage of them is in the lighter classes below 1-ton pay-load, averaging, perhaps, 15 cwt. There have never been more than 1;000 electric goods vehicles made in this country in one year whereas petrol goOds-vebicIe output is over 20 times that figure. Three manufacturers share in the proIluction of the 20,000 v.ehicles, whereas over a dozen makers bid for the battery-electric business. In such circumstances, the economic productian of electrics is, obviously, impossible, and the price is accordingly too high to attract any big volume of business, and without demand a competitive price is unattainable. Thus the position resolves itself into a vicious circle, tint, as already hinted, there is a way out, although it may be a painful one for those at present engaged in the electric-vehicle industry.

One reason why the petrol-vehicle manufacturer, who ,makes those types of small-load rating that compete with the electric, can 'produce at such a reasonable figure is because use is made of many of those components that are embodied in the private cars that are also built; it must be remembered that many makers of the lightest types build vehicles for both spheres. The result is that there are no additional tool charges to be met, as these will already have been written off in the car section: Such a useful advantage is not possessed by makers of battery-electrics.

The production of electrics consists in assembling into a frame components purchased from specialists who make such units for manufacturers of petrol vehicles. Obviously, the price of such parts is not so favourable as that charged to the petrol-vehicle maker, who has -probably paid all, or part, of the tool charges. On the other hand, the battery-electric maker could not possibly produce, in his own shops; axles, steering -gear, wheels, etc., atUnything like the price he has to pay to the specialist manufacturer.

There are indications that several manufacturers are . looking into the possibilities of.putting electric road traction on to a. more economic footing after the war. , These interests have, seemingly, become convinced of the fundamental soundness of the scheme, and are setting about making arrangements to remove what appears to be the only deterrent to it—that of high price.

• Should such interests as those engaged in the electrical or the petrol-vehicle industries take a hand in the , game, they would start off with advantages not possessed by the existing makers of electric vehicles. Of the two, the vehicle manufacturer would have the greater advantage, for reasons already given. On the other hand, the electrical people would have an advantage from the equipment point of view. It would not be impossible for either to undertake the manufacture of each other's speciality, and thus become self-contained.

There are other sources available for bringing down the high price of the leatterk-electric to a point where it could offer 'effective competition to the petrol van, and the battery and the charger can be mentioned in this connection.

The cost of these two components of an electric, the price of which is £325, is, respectively, between £80 and £100, and £40 and £50. Although, like everything else on the vehicle, they are purchased components, they are equally affected by the general economics of large or small volume output.

In a scheme of post,war production, it is a point of enormous importance that the cost of these two components can be eliminated from the price of the vehicle. They can be hired, instead of purchased, thus considerably reducing the first cost of the machine. An important point, bearing upon this matter, is. the fact that despite the increase in running costs, due to the hire charge, those costs are still well below those of the competing petrol vehicle. Under existing conditions, most costs of electric traction are lower, including current, tyres, maintenahce, lubrication, insurance and garaging.

In some cases, taxation is also lower.

Generallyspeaking, in the design of the post-war battery

, electric, light metalsi such as aluminium and magnesium will be largely employed, as the enormous increase in the production of these metals should result in their being available at prices which would make their employment economically possible. Every pound in weight taken off the chassis could provide for greater battery capacity, with consequent increases in range or of speed, or a combination ofthe two. Plastics, too, will have further developed, and will provide some alternatives to steel. Some plastics are already of the order of 25 to 30 tops tensile.

A2S Operating voltages vary considerably on different makes of vehicle, and may he anything from 24 to 160 volts. Nor is there any uniformity in voltages as, in vehicles of similar type and size, we_ find 88 volts supply in one case and in the other 160 volts. The current flow is of the order.of 50 to 60 amps., and road speeds vary from 10 m.p.h. to 15 m,p.h.

The advantage of an operating voltage in the region of 150 is that the charger has to take care only of converting the current from alternating to direct, and not stepping down the voltage. This saves cost in that no transformer is required. The question of battery charging, however,

might be solved by instituting a. battery-service scheme, whereby the operator neither owns nor is responsible for battery maintenance.

War conditions have enforced battery-electric developments in some countries, wheneconomics alone have been unable to do so. Although the information is somewhat sparse, it is clear that Sweden and Switzerland have both carried out work on such vehicles. Conversion of existing machines, and the fitting of electric equipment to new vehicles, have been carried out. Car starter-motors, as well as car batteries, have been used for many of these conversions, but the new equipment is specially manufactured for the purpose, and has been fitted to a number of 3-ton lorries.